This post is an excerpt from the journal ISA Transactions. All ISA Transactions articles are free to ISA members, or can be purchased from Elsevier Press.

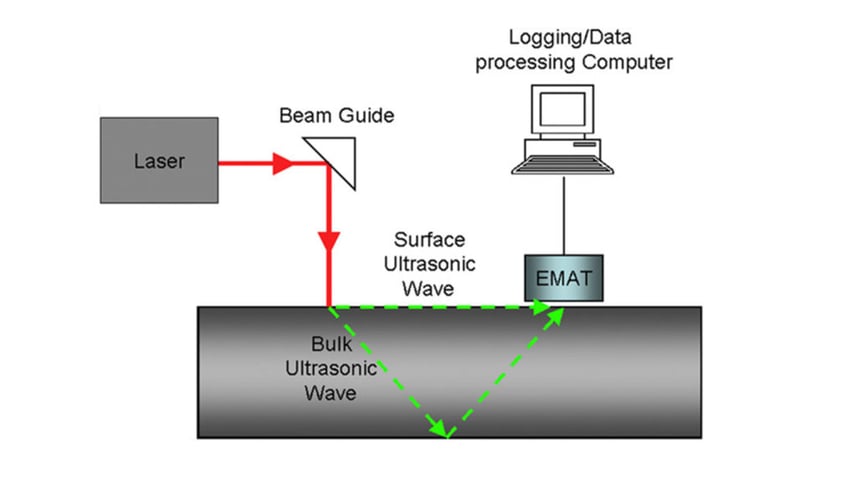

Abstract: Non-destructive test systems are increasingly applied in the industrial context for their strong potentialities in improving and standardizing quality control. Especially in the intermediate manufacturing stages, early detection of defects on semi-finished products allow their direction towards later production processes according to their quality, with consequent considerable savings in time, energy, materials and work. However, the raw data coming from non destructive test systems are not always immediately suitable for sophisticated defect detection algorithms, due to noise and disturbances which are unavoidable, especially in harsh operating conditions, such as the ones which are typical of the steelmaking cycle. The paper describes some pre-processing operations which are required in order to exploit the data coming from a non destructive test system. Such a system is based on the joint exploitation of Laser and Electro-Magnetic Acoustic Transducer technologies and is applied to the detection of surface and sub-surface cracks in cold and hot steel slabs.

Free Bonus! To read the full version of this ISA Transactions article, click here.

Join ISA and get free access to all ISA Transactions articles as well as a wealth of other technical content, plus discounts on events, webinars, training & education courses, and professional certification.

Click here to join ... learn, advance, succeed!

2006 Elsevier Science Ltd. All rights reserved.