Internet of Things (IoT) concepts and technology continue to create a great deal of interest, activity, and new industrial automation industry initiatives. The IoT concepts and technology are having a big effect on information technology (IT), consumer products, medical products, the automotive industry, and other applications. The industrial automation industry, typically a late adopter of technology, is not leveraging IoT and related technologies at the pace of these other segments.

IoT describes a connected world from the “edge” (sensors and actuators/controls) using computer applications (embedded, on-site computing, and cloud computing) to improve and expand efficiency and productivity in a wide range of use cases. IoT edge devices leverage the connection of uniquely identifiable electronic devices using the Internet “data plumbing,” including Internet Protocol (IP), Web services, and cloud computing. Each edge device is uniquely identifiable within the Internet infrastructure of wired, wireless, and cellular communications. Broad applications using IoT concepts and technologies are often referred to as cyber-physical systems, such as smart grids, intelligent transportation, and smart homes, factories, and cities.

New technologies continue to drive this growth with IoT leveraging a range of technological innovations and open standards that have made pervasive communications (voice, data, and video), computing (smartphones, tablet computers, cloud computing), embedded computing (smart appliances, personal fitness trackers), and sensing (microelectromechanical systems, GPS) possible. The integration of all these functions into single-chip computers is dramatically increasing capabilities and lowering costs. The majority are in high-volume applications in business to business, business to consumer, and consumer to consumer.

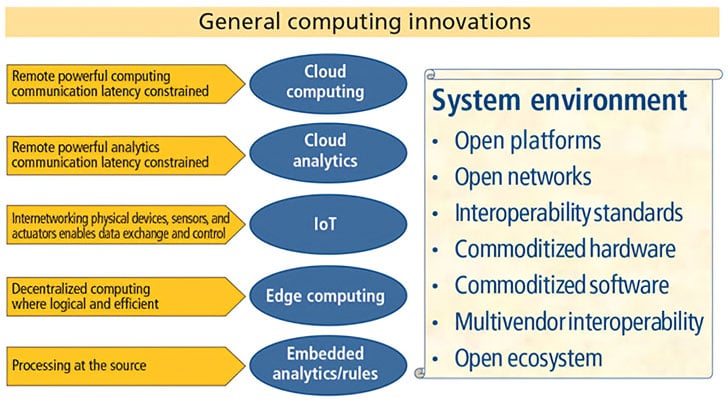

- Cloud computing: Cloud computing leverages shared resources and economies of scale similar to an electric utility. The cloud deliverscomputing power and massive storage on demand. This model transforms a traditional capital expenditure of investing in dedicated hardware to an operating expenditure where you "pay as you go" or pay for use. One advantage is enabling users to focus on projects instead of infrastructure and software administration details. Cloud storage, for example, can be used as a plant historian. The constraint on cloud computing communications is latency, because it is remote.

- Cloud analytics: Cloud analytics for predictive maintenance, optimization, and other use cases is a way to provide powerful analysis without having to invest in local computing.

- IoT: High-volume Internet of Things products and applications are driving the creation of low-cost, high-power computer chips with integrated communications and low-cost sensors to be the bedrock of cyber-physical systems.

- Edge computing: Edge-of-network devices, including Ethernet switches, sensors, actuators, and video cameras, are incorporating open, embedded computing platforms that allow users to download executable applications.

- Embedded analytics/rules: Embedded computing in edge devices, sensors, and actuators enables analytics and rules engines running distributed in the field (e.g., wireless analyzers attached to an electric motor frame that relays operational and predictive maintenance information).

IoT is starting to create a world that is more connected, with the application of pervasive communications, economical sensors that enable powerful analytics, and predictive software. Edge-of-network devices, including smartphones, tablet computers, personal fitness devices, smart sensors and analyzers, and people sensors, illustrate new possibilities from the leaps of technology. IoT and related innovations and broad ecosystems are making implementation of solutions easier with fewer technical skills required. Every day—using apps and applications like Salesforce, LinkedIn, Facebook, and Snapchat—people are doing things that not many years ago required programmers. The effect as this grows will be dramatic. IoT technologies empower people to use new tools to accomplish more. This is analogous to the impact of spreadsheets, PC databases, Visual Basic, and word processors in the past. They empowered people to leverage computers without programming. Think back to the day when spreadsheet software was introduced, eliminating the need to ask a programmer to create reports and analysis.

Powerful, low-cost cloud computing, wired and wireless communications, and systems-on-a-chip for embedded computing are fueling IoT.

Powerful, low-cost cloud computing, wired and wireless communications, and systems-on-a-chip for embedded computing are fueling IoT.

Ecosystems

Broad, open ecosystems, including Windows, iOS, Android, Linux, telecommunications, and the Internet, have enabled a wide range of solutions and unleashed the creativity and innovation of developers worldwide. These ecosystems are shared platforms that use more human and investment capital to create solutions than any single company.

Low cost, high value

A number of edge devices on the market today provide high capabilities at low cost. A great example is the Fitbit, which incorporates processing, sensors, display, and wireless communications supported by a cloud application. A teardown analysis performed by IHS Teardown Services revealed that the Fitbit Flex, which retails for $99.95, costs $17.36 to make, including material and manufacturing costs. This includes the wristband, enclosure, 32-bit ARM Cortex-M3, 32-MHz CPU, 128-KB Flash, 16-KB SRAM, 24 Channel x 12-bit analog-to-digital converter, Bluetooth wireless, three-axis accelerometer, battery, and vibration motor. This is essentially a wireless supervisory control and data acquisition (SCADA) system. It is a glimpse into a possible future of industrial automation with end devices, such as sensors, actuators, motors, and valves, having embedded processing and communications.

Human sensors

The notion of sensors placed on humans opens possibilities to improve resource utilization, productivity, and safety. One example today is wearable technology, including interactive eyeglasses providing employees with manuals, real-time data displays, and real-time assistance from remote experts.

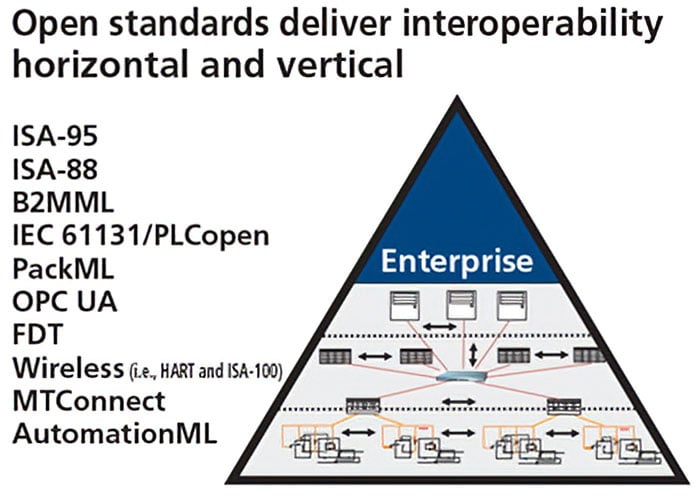

Technology innovations coupled with open standards create open multivendor ecosystems leveraging open, multivendor interoperability.

Technology innovations coupled with open standards create open multivendor ecosystems leveraging open, multivendor interoperability.

Industrial automation

The industrial automation industry has always leveraged commercial technologies after they become mainstream in commercial applications. Examples include programmable logic controllers displacing banks of relays, commercial PCs displacing custom-built CRT consoles, digital control displacing pneumatic/analog electronic control, Ethernet (802.11) displacing proprietary communications, and 802.15.4 wireless sensors. The bottom line is the application of new technology over the years has reduced the total cost of automation system ownership, while increasing the value delivered and creating more possibilities for automation and optimization.

IoT and industrial automation

IoT is creating a flood of new technology and tools for the automation industry to use to solve problems, improve operations, and increase productivity

There are many existing industrial standards that support IoT principles.

There are many existing industrial standards that support IoT principles.

This comes at a time when many believe the technology gap between state-of-the-art technology and industrial automation systems has widened significantly. Don Bartusiak, chief engineer at ExxonMobil Research and Engineering, challenges users to think about this with these questions and rhetorical answers:

“Would you accept a Verizon cell phone that could not talk to Sprint, AT&T, or Vodafone cell phones? This is where we are with industrial automation today!

“If you switched your computer from a Dell to an HP or Lenovo would you accept having to rewrite all your Word documents, spreadsheets, presentations, and other documents? This is where we are with industrial automation today!

“Would you accept the requirement to have a dedicated router for your Dell computer, a second router for your Apple computer, and a third router for your Android computer? This is where we are with industrial automation today!”

Manufacturing is ripe for a revolution, and leveraging these new concepts and technologies makes it possible. IoT concepts and technology are only recently starting to be considered and adopted for industrial automation applications. Not surprisingly, industrial automation systems are designed conservatively and adopt new technology when it is stable.

The last major adoption of commercial open technology with an open ecosystem in industrial automation was replacing proprietary system software with Microsoft Windows–based “front ends” and human-machine interfaces. Connectivity with open databases, spreadsheets, and enterprise resource planning changed from unique proprietary interfaces to open standards, including Open Database Connectivity, dynamic data exchange, and OPC, creating an ecosystem of creative developers building innovative and useful applications for a range of industries.

The success of the Internet and now IoT is not simply applying the latest technology, but creating ecosystems that expand the creative contributors with open, interoperable standards. Many industrial automation vendors are embracing cloud analytics and historians in various ways, because they add incremental value and only require making their proprietary data available through software and hardware gateways to their closed ecosystems.

Complete visibility

Attaching sensors to machines and processes lets companies track progress and receive immediate notification of issues. This improves productivity, efficiency, responsiveness, and economic results. Customers and suppliers can be given real-time visibility to achieve accurate, just-in time production, optimizing inventory with precise real-time information.

Is this your old SCADA/automation system with new technology?

Many industrial automation vendors believe the present SCADA and industrial automation systems have been doing IoT functions for years, and the application of IoT concepts and technology to existing offerings can be used to incrementally improve existing industrial automation architectures and devices.

There is some truth in these thoughts, but this is the same type of thinking that mainframe and minicomputer manufacturers had when there was an influx of new technologies and open ecosystems in the computer industry that they resisted when PCs were coming on the market. PCs leveraged highly integrated microprocessors, TCP/IP Ethernet and open systems software (DOS, Windows), and open hardware platforms (Industry Standard Architecture Bus, Extended Industry Standard Architecture Bus, Peripheral Component Interconnect Bus, and Universal Serial Bus) that created an ecosystem of highly creative and productive application developers. They naturally improved competition, value, and cost.

The shift to open unleashed creativity and innovation that brought to market a wide range of solutions that dramatically expanded the computer hardware and software industry. The winners in the computer industry learned a lesson—open systems dramatically increase the number of applications and expand the market by enabling more applications.

IoT-spawned initiatives

The influx of IoT concepts, technology, and architectures has been a big factor in the development of industrial automation initiatives, including:

- The Open Process Automation Forum: Focused on developing a standards-based, open, secure, and interoperable process control architecture

- Industry 4.0: Industrial automation architecture for cyber-physical systems to create smart factories using IoT and other new technologies

- Industry 4.0 for Process: The application of Industry 4.0 concepts to improve process automation given the advanced technology available

Keep sight of the goals

The danger with new “shiny” technology is staying focused on the goals, such as applying automation to increase productivity and leverage data to competitively manufacture quality products at a profit. Major functions include synchronized manufacturing, advanced optimization, predictive maintenance, and tracking and tracing.

These shifts in technology have worldwide implications for manufacturers, enabling more companies to compete. Rather than getting mesmerized by new technology, it is important to focus on high-level goals to improve quality, uptime, and efficiency, and to drive out the labor cost of production. IoT is a set of concepts and technologies to interconnect, orchestrate, and optimize across the entire value chain of industry, including suppliers, manufacturers, logistics, and users.

To be competitive in their industry, the big question users should consider is which new IoT technology-based solutions are stable and add value. Those will be the worthwhile investments.

Industry perspectives

I asked some industry analysts for their thoughts on the subject:

Greg Gorbach, vice president and IIoT team leader, ARC Advisory Group

“At ARC, we view IIoT [Industrial Internet of Things] as much more than simply connecting industrial things to the Internet or to each other. IIoT includes that, but also includes a collection of technologies from network communications up to the cloud, including analytics and software. IIoT impacts two distinct areas: IIoT for industrial operations and IIoT for products and services.

“In the plant or factory, there are significant opportunities to optimize maintenance by improving asset uptime through predictive maintenance techniques and by using machine health data. There are also significant opportunities to improve production performance, worker safety and efficiency, quality, and responsiveness.

“Apart from industrial production, IIoT also offers tremendous potential for industrial companies that build smart, connected products for which they can offer new services enabled by the real-time information available from those connected products.

“Both areas—IIoT for industrial operations and IIoT for products and services—offer significant potential to improve the supply chain, design and engineering, business systems, and customer intimacy.”

Patrick Moorhead, president and principal analyst, Moor Insights and Strategy

"The bottom line is that manufacturers need to embrace IoT or risk losing business and even their entire business. Early IoT manufacturing rollouts have demonstrated that over the midterm, they can improve quality and even enable new XaaS [everything as a service] business models.

"First off, take a sobering and realistic view that you are just starting, so have a big strategy, but start with small projects and get some quick wins. Speak in customer and financial terms internally, not technical.

"I recommend setting up a cross-functional project team with two business leaders from both IT and OT [operational technology]. Also, scope those first projects small to get some quick wins."

Matthew Littlefield, president and principal analyst, LNS Research

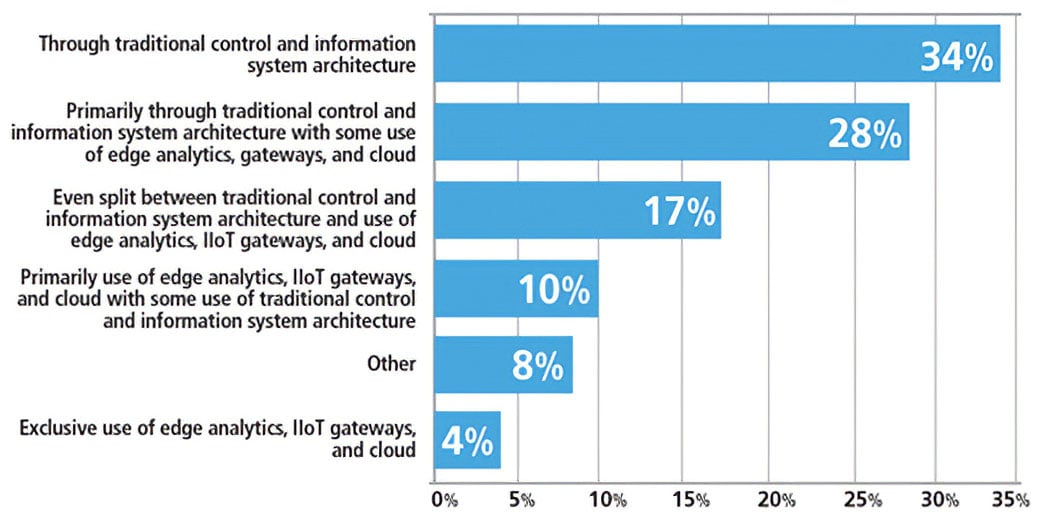

“In less than a year, we have seen over a 50 percent reduction among industrial companies that don’t know about or understand the IIoT. Two-thirds of industrial companies surveyed are already using some type of hardware and data architecture that flows information outside the traditional ISA-95 hierarchical model.”

Keep sight of the goals

The danger with new “shiny” technology is staying focused on the goals, such as applying automation to increase productivity and leverage data to competitively manufacture quality products at a profit. Major functions include synchronized manufacturing, advanced optimization, predictive maintenance, and tracking and tracing.

These shifts in technology have worldwide implications for manufacturers, enabling more companies to compete. Rather than getting mesmerized by new technology, it is important to focus on high-level goals to improve quality, uptime, and efficiency, and to drive out the labor cost of production. IoT is a set of concepts and technologies to interconnect, orchestrate, and optimize across the entire value chain of industry, including suppliers, manufacturers, logistics, and users.

To be competitive in their industry, the big question users should consider is which new IoT technology-based solutions are stable and add value. Those will be the worthwhile investments.

Source: LNS Research report, IIoT and Big Data Analytics: How manufacturing System Architecture is Being Transformed

Source: LNS Research report, IIoT and Big Data Analytics: How manufacturing System Architecture is Being TransformedA version of this article also was published at InTech magazine.