This post is an excerpt from the journal ISA Transactions. All ISA Transactions articles are free to ISA members, or can be purchased from Elsevier Press.

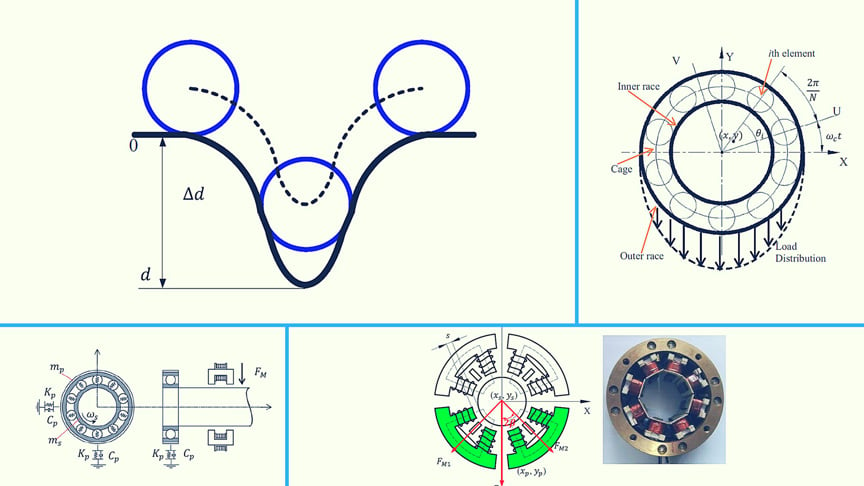

Abstract: The active health monitoring of rotordynamic systems in the presence of bearing outer race defect is considered in this paper. The shaft is assumed to be supported by conventional mechanical bearings and an active magnetic bearing (AMB) is used in the mid of the shaft location as an exciter to apply electromagnetic force to the system. We investigate a nonlinear bearing-pedestal system model with the outer race defect under the electromagnetic force. The nonlinear differential equations are integrated using the fourth-order Runge–Kutta algorithm. The simulation and experimental results show that the characteristic signal of outer race incipient defect is significantly amplified under the electromagnetic force through the AMBs, which is helpful to improve the diagnosis accuracy of rolling element bearing's incipient outer race defect. The rolling element bearing is one of the most common components in rotating machinery. The health condition of these bearings directly determines the performance of the rotating machinery. Defects in bearings that may occur during operation or the manufacturing process can cause vibration, noise, and even system failure. It is thus critical to detect the defects in bearings at their initial stage to prevent catastrophic damage or failures to the rotating machine, resulting in plant downtime and reduced efficiencies.

Free Bonus! To read the full version of this ISA Transactions article, click here.

Enjoy this technical resource article? Join ISA and get free access to all ISA Transactions articles as well as a wealth of other technical content, plus professional networking as well as discounts on technical training, books, conferences, and professional certification.

Click here to join ... learn, advance, succeed!

2006-2018 Elsevier Science Ltd. All rights reserved.