Artificial intelligence (AI) is one of the biggest buzzwords for 2020 and will only continue to become more popular in the future as we start to fully capitalize on its potential. For those new to the subject, you might wonder why you almost always see the concept “artificial intelligence” accompanied with “machine learning?”

What are they? How are they different? Where can they be applied in an industrial setting? Why are they so important? Similar to many other terms that have arisen through Industry 4.0, artificial intelligence and machine learning seem to be often overused and misapplied. This article attempts to clarify the difference without any of the marketing hype.

AI & ML Defined

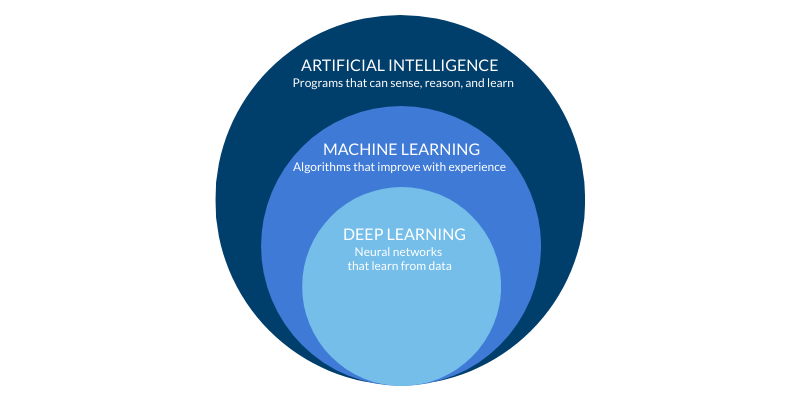

Artificial intelligence is a technique that enables machines to imitate human behavior. Machine learning (ML) is a subset of AI that uses statistical methods to improve over time as it gains experience. There are many types of artificial intelligence, encompassing topics like natural language processing, image recognition, and smart robots.

Artificial intelligence has the ability to sense, reason, and learn. Machine learning, which is the basis of many artificial intelligence systems, only has the ability to make predictions on outcomes. While ML can identify differences in patterns of data, it will never understand what it is actually doing. AI will use the results of machine learning, along with other analytical methods, to arrive at some level of intelligence.

Diagram of interrelationships: artificial intelligence, machine learning, and deep learning

Difference

Machine learning is tasked with making binary decisions. Something is either true or it is not. Over time, the method used to make the decision is improved, leading to greater confidence that the decision is the correct one. Facial recognition is a classic example of machine learning. It is either you or it is not you in a picture. Artificial intelligence, on the other hand, uses the combined decisions of many inputs to improve all of them. It draws from many different aspects of the decisions. If you appear often in photographs with another person, artificial intelligence will learn from this experience and update the machine learning algorithm to improve the decision process.

Application

The most common application of machine learning is pattern recognition. Using supervised learning, a machine learning algorithm is provided a robust set of data. Two of the most common learning methods are regression and decision tree. The programmer identifies the conditions that are of interest. The algorithm will then look for similar conditions in the future.

Machine learning systems are often applied to monitor asset health. For example, vibration analysis is used to detect issues with a bearing in a rotating piece of equipment. Using machine learning, an algorithm is provided a large set of vibration data, perhaps several years’ worth, and identifies patterns in the data. The programmer will identify the times a bearing failure occurred in the data set. The system will make a decision, along with a level of confidence. For instance, the system could be 90% confident the bearing will fail within six weeks.

Where artificial intelligence comes into this situation is through the use of other data analytics methods. This may be the introduction of manufacturing data, like process data or quality data. The AI system will then seek to enhance the machine learning algorithm to better detect bearing failures. It also has the capability to provide the best conditions to achieve some desired outcome. Perhaps there is a planned shutdown in eight weeks. The AI system will provide the conditions needed to enhance the likelihood the bearing will not fail before then.

Importance

ML and AI techniques will become critical to success in manufacturing. Through the ability to capture more data and the use of analytic tools, better decisions can be made faster. This will dramatically improve both operational and business efficiency. Processes can be improved by optimizing certain parameters while constraining other values—for instance, maximizing efficiency while maintaining quality. Purchasing decisions can be optimized during varying market conditions. As noted above, equipment can be operated at optimized levels.

Conclusion

A word of caution before trying to implement artificial intelligence and machine learning. While there are many benefits of using them in your business, they should not be the first step in your digital transformation. You will need to have a system that has a significant amount of computational power. It is recommended you explore a cloud architecture as these systems can be scaled to meet your application needs.

Data quality is also critical to the success of these efforts. The adage of “garbage in, garbage out” certainly applies. But once your data is correct and organized, and you have the power to process it, artificial intelligence using machine learning will most certainly lead to the aforementioned outcomes.

This article is a product of the International Society of Automation (ISA) Smart Manufacturing & IIoT Division. If you are an ISA member and are interested in joining this division, please email info@isa.org.