As a concept, how can we define data analytics? Let's break down the term. Analytics is the process through which we turn data into usable information. Data is defined as the core, primary, raw readings from a measurement.

Raw data requires metadata (data associated with the primary data) to provide context and meaning. With that context, raw data becomes information: an interpretation of data that helps inform a decision or answer a question. Here is an example to illustrate how metadata can give data context and meaning:

- 62 is data

- 62 degrees Fahrenheit is data with additional metadata, providing more useful details

- 62 degrees Fahrenheit at 3:22 PM EST on April 4, 2021 is data with an additional series of contextualized metadata, making it a dataset

"Analytics" describes a set of tools that interprets datasets to provide more advanced insights to answer more complex questions. Those tools can include statistical analysis, trends and visualizations, and machine learning—anything that helps convert the raw dataset into useful information.

Image source: Principa

Image source: Principa

Types of Analytics

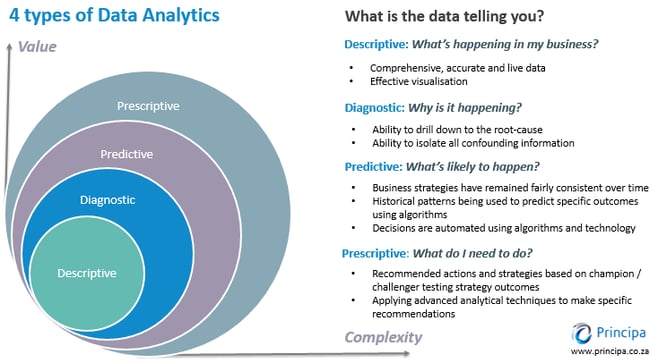

Common categories of data analytics include descriptive, diagnostic, predictive, and prescriptive.

Descriptive analytics looks to the past to describe what has already happened. You may use descriptive analytics to answer the question, "How many orders for Widget A do we usually get in November?" You could analyze data from all orders over the past five years to calculate an average order quantity.

Diagnostic analytics provides more insights into why something happened, often to find a root cause or to compare descriptive analytics. To understand why a company tends to get more orders for Widget A in November than it does in December, for example, you may compare the average orders for each month with external factors like advertising campaigns or voice-of-customer surveys.

Predictive analytics is used to anticipate what may happen in the future. If you wanted to know how many orders for Widget A this company should expect this November, you may run a different analysis to see that order quantities have been steadily increasing year-over-year, and that you can expect 10% more orders this year than last.

Prescriptive analytics, also looking to the future, suggests the best course of action to achieve a desired outcome. Prescriptive analytics aims to help provide guidance around questions like "Where should I invest in my manufacturing process to increase Widget A production capacity to meet the forecasted increase in demand?" Prescriptive analytics has the most value, but it is also the most complex.

Analytics in Manufacturing

It is easy to see how advances in analytics have changed our relationship with data and how we use it to inform decisions in a manufacturing environment. Popular use cases include:

- Supply chain teams can analyze data on perfect order fulfilment rates, historic and predicted demand, and manufacturing efficiency rates to help determine optimal production schedules and reduce on-hand inventory

- Plant managers can assess the utilization of their manufacturing assets and the root causes that detract from optimal output, then use this information to help determine how to reach new production targets

- Operations teams, aided by batch analysis tools, can use prior performance to predict if a current production run is trending in the wrong direction—and can make corrections in-flight

There are a number of technologies that enable manufacturers to realize these use cases, including:

- Technologies that make more factory-floor data available to analytics platforms, like process historians, IIoT-enabled sensors, edge devices, and communications protocols like OPC-UA and MQTT

- Connectivity solutions that make it easier to combine data from various sources, like SCADA, MES, ERP, PLM, WMS, and SCM systems

- Analytics platforms themselves, especially those that automate and streamline the process of turning raw data into valuable insights (for example, software that can identify phases of a continuous process or cleanse bad-quality data). This also includes the exciting and innovative subject of machine learning, where guided computer algorithms can automatically process datasets at rapid speed to provide insights with minimal human intervention

The Future of Analytics

The future of analytics can be summed up in one word: more.

We may soon see more manufacturing assets contributing to datasets through IIoT devices and advances in networking. Previously siloed data sources may soon experience more connectivity and collaboration. Advancements in computational power and analytics tools may enable more in-depth insights. More ready-made use cases may provide more value out-of-the-box. And more people will be eager to leverage these tools and insights to perform their jobs better.

Data analytics is a fundamental building block of the Industry 4.0 toolset. It is how we take advantage of modern advances in connectivity, computing, and technology to provide valuable insights and make better operational decisions every day.

This article is a product of the International Society of Automation (ISA) Smart Manufacturing & IIoT Division.