Companies that can best optimize their cyber-physical systems and their workforce will be the winners in their market, and digital transformation is the key to that success. But adoption of digital transformation technologies like the industrial internet of things (IIoT), big data, and data visualization has been uneven across market sectors.

What do engineers and managers need to know about digital transformation, and how can becoming a digital transformation expert transform your career?

Free On-Demand Webinar

In February 2023, subject matter experts from the International Society of Automation (ISA) presented an informative webinar entitled, "Responsible Disruption: What Engineers Need to Know about Digital Transformation."

Speakers included Steve Mustard, former ISA President and President and CEO of National Automation, Inc.; Dave Lafferty, President of Scientific Technical Services; and Scott Sommer, Department Manager, Instrumentation & Control with DPS Group Global.

Watch the webinar and access the slides here:

What is Digital Transformation?

Digital transformation is fundamentally changing how an organization operates by the adoption of digital technology to increase value through innovation, invention, customer experience, or efficiency.

The concept of digital transformation is often confused with Industry 4.0.

Industry 4.0 is about using digital to gain a competitive advantage, much like steam engines, assembly lines, and industrial robots did in previous industrial revolutions. But it may not necessarily include changing behavior.

Digital transformation is a more substantial change that impacts the way that business is conducted - it is as much a shift in mindset as it is the adoption of technologies.

Digital, Digitalization, Digital Transformation - What's the Difference?

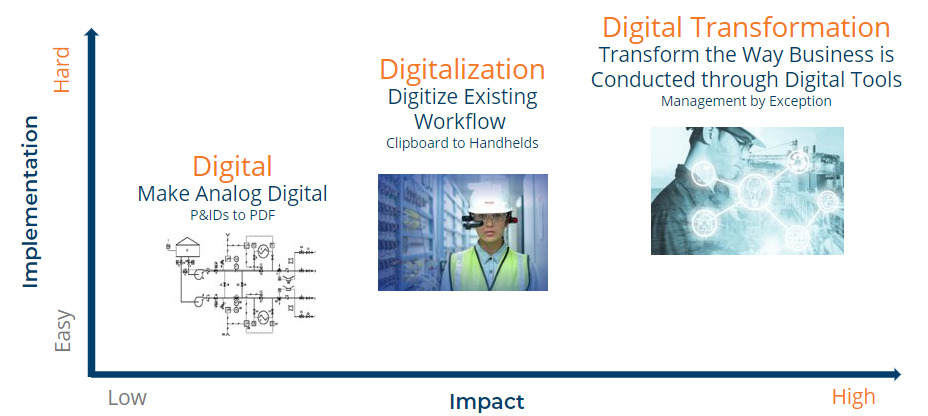

There can be confusion about what it really means to enact a digital transformation, and so it's important to consider the different steps along the way.

Making analog files digital and shared across the organization is a clear first step, and something that a lot of organizations already do. This is easy to implement, but relatively low impact in terms of the total digital transformation journey.

An intermediate step is digitalization, where teams take an existing workflow - such as walking the plant floor with a clipboard performing inspections - and digitize it. For example, inspectors may use tablets to update data or may even wear augmented reality tech like smart glasses. The use of these technologies can allow users to access documentation from central repositories, and allow them to record measurements, readings, and observations in terms of notes, photographs, and videos. All of this information can be easily associated with specific locations, making the processing of a report much simpler.

The final step is true digital transformation - where digital tools fundamentally change (and improve!) the way business is conducted. An example shared during the webinar was relying upon machine learning to identify corrosion through image analysis. Advanced analytic engines predict where corrosion issues are developing and reduce the need for manual and potentially biased analysis. Machine learning also may result in the early identification of potential issues that might otherwise be missed.

People and Culture

Digital transformation is not a project. It is a journey.

It is also not something that one determined and passionate engineer can will into reality.

This journey involves much more than just implementing new technology. It involves the people and culture of an organization, as well as its business capabilities. And of course, there are always regulatory and compliance considerations at play.

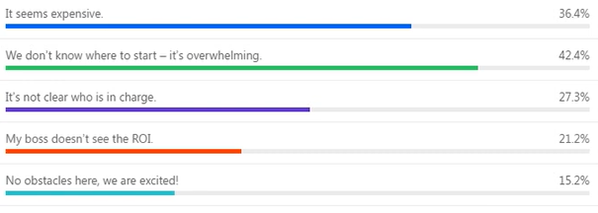

Webinar attendees were asked to identify the biggest obstacles to putting digital transformation in place within their organization:

42% of respondents said, "We don't know where to start - it's overwhelming."

42% of respondents said, "We don't know where to start - it's overwhelming."

Other concerns centered around the cost, lack of clarity around who is in charge of the project, and whether return on investment (ROI) was demonstrable.

But 15% of respondents said, "No obstacles here, we are excited!" That's great news, and we will doubtless see that type of response become more and more common as digital transformation becomes increasingly prevalent across industrial and manufacturing sectors.

Digital Transformation Training Series

Demystifying digital transformation is critical to ensuring that these common objections can be easily addressed. ISA offers training that will provide you with all the tools necessary to actively and efficiently participate in digital transformation projects at your plant site or organization:

Introduction to IIoT — The Industrial Internet of Things (DT101)

Sign up any time for this self-paced modular course. It covers the basic concepts of the internet of things and how these concepts and underlying technologies have evolved, and how they are currently being applied to industrial applications. It also covers supporting technologies that are often employed in IIoT applications in greater detail, including:

- Machine learning/AI

- Data preparation/cleansing

- Data analytics

- Data presentation technologies

Participants will review actual IIoT projects in greater depth and examine these projects' technical and business aspects, giving registrants deeper insights into IIoT applications.

Join Us at an Event

ISA’s 2023 line up includes four hybrid events for automation and cybersecurity professionals. While digital transformation is the specific focus of two events, the topics addressed at all four events will be of interest to those looking to move digital transformation forward at their organization:

- OT Cybersecurity Summit, Aberdeen, Scotland, 31 May – 1 June

- Digital Transformation Conference, Brazil, September

- Automation and Leadership Conference, Colorado Springs, CO, 4 – 6 October

- Digital Transformation Conference, Asia Pacific, November