This guest post was authored by Pekka Videnoja, professional services manager at Beamex, in conjunction with an ISA co-hosted webinar series on calibration. Click this link to watch the first webinar in this two-part ISA technical series on how to avoid the pitfalls of implementing a calibration process change.

Editor's Note: This is Part 2 of a two-part series on avoiding the pitfalls of implementing a calibration process change. To watch Part 1, click this link.

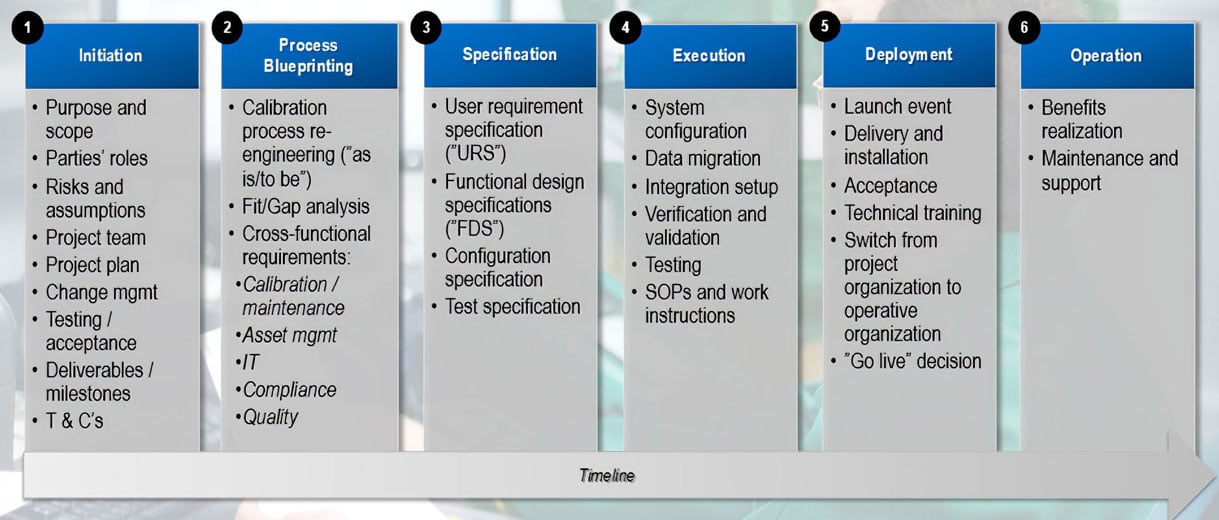

After you have made the decision to get out of your calibration rut, the next step is to outline a system implementation process. Remember that implementing a fully integrated, automated calibration solution is a process. It simply won’t happen overnight, and needs to be done in steps. Before talking about the steps, let’s review a few fundamentals to keep in mind:

- There are a large number of interrelated tasks that need to be carried out in an appropriate sequence. Every step is important and decisions need to be made throughout the process.

- Utilizing a proven implementation model will be a faster process than a new, or extremely customized solution.

- The implementation process is usually overseen by a project manager and requires involvement of several professionals.

- The biggest problems (e.g. scope creep, budget and schedule overruns) are usually caused by poor planning and inadequate resourcing, rather than the individual steps being particularly difficult.

Six Steps of a Calibration System Implementation Process

1) Initiation

In this phase, the entire framework for the project is established. A target “go live” launch event is defined, as well as the purpose and scope for the new calibration system. Furthermore, in this phase you appoint the project team, prepare a project plan and establish certain important rules and principles for the project, such as testing and acceptance procedures and change management for managing changes in the project requirements.

Also, it is very important that you define the roles and responsibilities of both the vendor and customer, as a calibration process change is never a “one man show” – actually the majority of the resource requirements typically relate to customer tasks and responsibilities. All of this must be then documented in the supply agreement, project plan, statement(s) of work and progress reports. To ensure a successful outcome, set milestones and continuously review your progress.

Some important items to keep in mind are the definition of all deliverables relating to each milestone. Remember that your vendor should help you with this, as their role is not just to provide a solution, but to act as a consultant, offering support and expert advice from delivery to full functionality.

This is perhaps the most important phase of implementing a new calibration system because this is when the existing calibration process is documented as well as the new target calibration process specified. The key question in the entire project is the ability to accept and adopt a new calibration process, as you cannot just introduce a new system and tools and assume that they can be used in accordance with the old legacy process.

However, if you feel that you are not capable of adopting the new process, you can still cancel the project in this phase and you have anyway learned a lot from your existing work procedures and new possibilities. Typically a significant amount of input from a number of users and cross-functional subject matter experts, such as IT, compliance and quality is required, as the calibration process has connections to many different areas. As much as you plan and have set your goals, more than likely there will be some unanticipated functionalities or specifications required. That is why it is important to outline processes, so, if such an instance arises, everyone knows how to respond.

3) Specification

The basis for this phase is set in the process blueprint. It is a common mistake to jump straight into the specification phase by skipping the initiation and process blueprinting phases. It is important to be sure that you are on the same page with your vendor in terms of technical specifications and functionalities, so both parties are working toward the same desired outcome. It is surprising how many different interpretations a single word can have, so going through the technical specifications in detail is very important task to ensure that everyone understands them in the same manner. User requirements, functional design and test specifications are all defined during this phase.

4) Execution

If the first three phases have been done well, this is the easy part. The plans prepared are ready to be executed, mainly by your vendor. If you notice something was not specified or requirements have changed or change, refer to the change management procedures you agreed upon with the vendor in the initiation phase, as the change management procedures are usually described in the supply agreement or project plan.

5) Deployment

The “go live” launch event defined in the initiation phase occurs during deployment. This is when all software, equipment and training is put into the end user’s hands and accepted by the customer. More than likely, the process and system must be “re-sold” to all stakeholders, therefore it is advisable to plan a launch for motivating people. Even if many have been involved in different phases of the process, this will help guarantee acceptance and a successful implementation.

6) Operation

The operation phase concludes the implementation of a calibration process change. The system is running and the expected benefits are realized. The new system is used in accordance with the new process that is well-documented with new standard operating procedures and work instructions and all are trained accordingly. Hopefully, you have chosen a supplier that offers strong customer support to have your back if something goes awry.

All in all, implementing an overhaul to your calibration process will take time and resources. After all of it is complete, you will be able to realize the benefits of your efforts through improved efficiency, accuracy and savings in time and money.

Click this link to watch Part 1 of the ISA co-hosted webinar series focusing on how to avoid the pitfalls of implementing a calibration process change.

Blog Posts

How Often Do Measurements Need to Be Calibrated?

Just in Time, or Just Too Late? A Kaizen Approach to Calibration

How to Improve Industrial Productivity with Loop Calibration

Temperature Calibration: Using a Dry Block to Calculate Total Uncertainty

How Can Advanced Calibration Strategies Improve Control Performance?

How to Calibrate a Pressure Transmitter

Webinar Recordings

Uncertainty in Calibration

Calibration Uncertainty and Why Technicians Need to Understand It

How to Avoid the Most Common Mistakes in Field Calibration

Learn Advanced Techniques in Field Calibration

How to Build an Industrial Calibration System Business Case

How to Use Calibration Tools for Accurate Process Temperature Measurement

How Does Low Flow Affect Differential Pressure Flowmeter Calibration?

Three Common Pitfalls of Pressure Calibration

How to Calibrate Differential Pressure Flowmeters

Free Downloads

ISA Industrial Calibration Worksheets

Measurement Uncertainty Analysis Excel template plus book excerpt

Calibration Handbook of Measuring Instruments book excerpt

In-Depth Guide to Calibration for the Process Industries eBook

Calibration Uncertainty for Non-Mathematicians white paper

About the Presenter

Pekka Videnoja is a professional services manager at Beamex. Pekka manages the Beamex professional services team and provides technical support to Beamex customers and the sales team globally. Pekka has been involved in software development and implementation for more than 14 years. He has master of engineering degree in strategic leading of technology-based business from Centria University of Applied Sciences and a bachelor of engineering degree in information technology from Oulu University of Applied Sciences.