The following insights are part of an occasional series authored by Greg McMillan, industry consultant, author of numerous process control books and a retired Senior Fellow from Monsanto.

Well-mixed liquid reactors have dynamics that offer the possibility of extremely tight control of product composition but lack some of the self-regulation in multiple phase reactors achieved by inventory control. For a reactor to achieve its full potential requires an  intelligent design of the control strategy. Here we look at how to set up the control loops based with some guidance as to how the loops change for batch, fed-batch, or continuous reactors.

intelligent design of the control strategy. Here we look at how to set up the control loops based with some guidance as to how the loops change for batch, fed-batch, or continuous reactors.

For reactions that are all in one phase (gas, liquid, or solid), inventory control (pressure or level control) cannot automatically adjust a reactant flow for changes in conversion (amount of product or byproduct formed per unit of reactant added) to prevent an excess or deficiency of reactant in a product phase (e.g., liquid) that is the opposite of the reactant phase (e.g., gas). Consequently, for single phase reactors, the use of analyzers is more important to control reactant stoichiometry for maximizing yield beyond what tight temperature control can do.

Insight: Single phase chemical reactors have a greater dependence on analyzers to maximize yield since there is not the inherent prevention of excess reactants by pressure or level control.

For well mixed single phase reactors the largest sources of improper reactant concentration leading to excess reactant are errors in reactant flow measurement and changes in reactant composition. Note that a deficiency in one reactant concentration creates an excess of another reactant. Coriolis meters can be used to provide the greatest mass flow measurement precision and rangeability with density correction for any changes in reactant feed concentration. Consequently, Coriolis meters on reactant feeds eliminate most of the sources of reactant unbalances if the mass flow ratios are correct and coordinated to maintain reaction stoichiometry.

Insight: Coriolis meters in reactant feeds are the best way to ensure correct stoichiometry if the feed setpoints are changed in unison with the correct ratio and the same closed loop response.

If the density of the excess reactant is significantly different than the density of the other components in the reactor, a Coriolis meter in the recirculation line can provide an inline inferential measurement of the excess reactant concentration to provide a fast and accurate correction of the ratio of reactants.

Insight: If changes in excess reactant concentration cause density changes greater than 1 percent and are at least 100 times larger than other density changes, a Coriolis meter in a recirculation line can be used as an inline analyzer for excess reactant concentration.

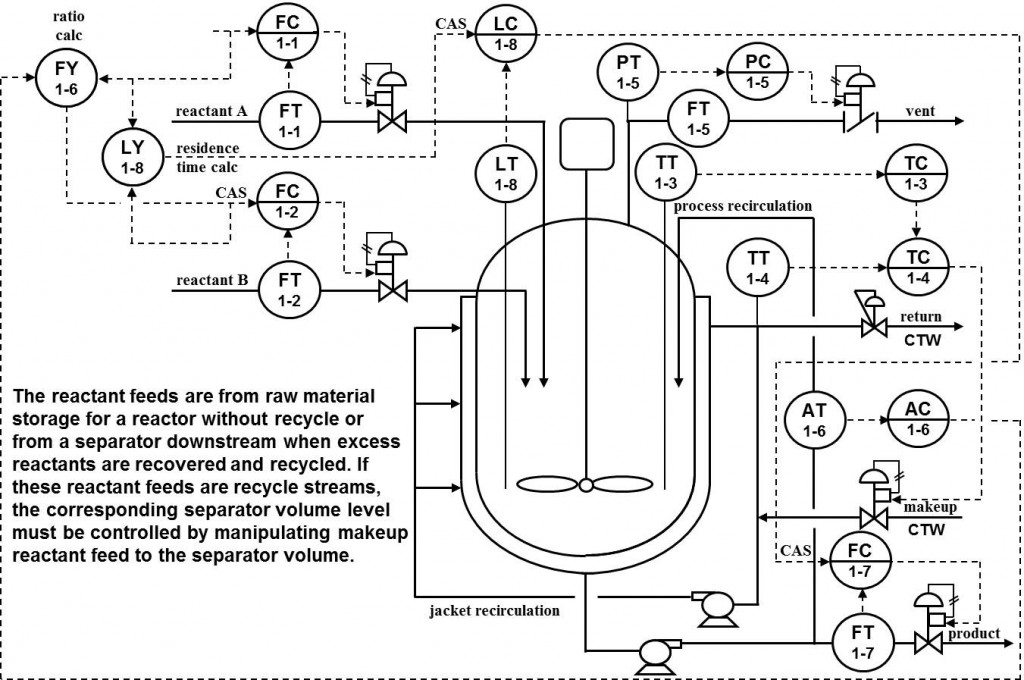

For continuous reactors with liquid reactants and liquid product, a level loop controls the inventory and thus the time available for reaction by manipulating the discharge product flow. If the desired reactor residence time multiplied by the total reactant flow is scaled and used as the setpoint of the level controller, the level loop helps maintain a constant residence time important to provide enough time for slow reactions. The reactor discharge flow is not used in the residence time calculation, to avoid the creation of a second loop within the level loop where a change in level PID output would cause a change in level PID setpoint which would cause a change in level PID output and so forth. The reactant feed setpoints are used instead of reactant flow measurements for the same reasons that setpoints are used in feedforward flow signals.

Well-mixed single liquid phase reactors have an excellent process time constant to dead time ratio but lack the ability for inventory control to inherently optimize excess reactant concentration. The use of accurate ratio control of reactant flows is critical. See Greg McMillan’s new ISA book, Advances in Reactor Measurement and Control, for an extensive view of practical opportunities for designing control strategies to achieve product quality and maximize yield and capacity in different types of reactors.

Batch reactors don’t have a level loop and the concept of a residence time is replaced with a batch time for available time for reaction. The rising level of a batch reduces any self-regulation that might exist; changes in heat or mass transfer with temperature and concentration affect the open loop responses of temperature and product composition necessitating the use of higher controller gains to provide sufficient closed loop regulation. Integral action is also more likely to produce overshoot of setpoint.

Insight: A liquid level controller with a setpoint proportional to production rate can help provide the necessary residence time for liquid reactants in a continuous reactor.

Temperature loops control the energy balance and the reaction rate through the Arrhenius equation for chemical reaction kinetics. A cascade temperature control system offers the greatest linearity and responsiveness to coolant pressure and temperature upsets. The reactor temperature PID manipulates the setpoint of a jacket inlet temperature control that in turn manipulates makeup coolant flow. The coolant exit flow, such as cooling tower water (CTW) return flow, equals the coolant makeup flow to the jacket by piping design and in some case by pressure control in the recirculation system. The resulting constant jacket coolant flow eliminates the increase dead time, process gain and fouling from a decrease in jacket flow. An enhanced PID is used for the jacket inlet temperature loop to prevent limit cycling from valve stick-slip.

Insight: Temperature control determines the reaction rate via the Arrhenius equation.

Insight: Cascade control of reactor to jacket temperature isolates the reactor temperature PID from most of the nonlinearities and disturbances associated the jacket temperature response.

For batch reactors, as previously mentioned there is no level control and hence no residence time control but otherwise the temperature and gas pressure control systems shown for continuous liquid reactors are generally applicable. The tuning is even similar since a large primary process time constant enables continuous liquid reactor composition and temperature loops to be treated as having a near-integrating response that is similar to the integrating response of batch reactors.

Insight: The temperature and gas pressure control systems and PID tuning for batch reactors and liquid continuous reactors are similar.

For pure batch operations where flows are sequenced and scheduled based on batch times and totals the concentration endpoint is achieved by accurate charging of reactants and by a batch cycle time long enough to insure complete reaction. The simultaneous feeding of reactants by flow loops whose setpoints can be manipulated termed fed-batch control or semi-continuous control opens up opportunities for the use of concentration control as the batch progresses. The control schemes for concentration control of excess reactants in continuous liquid reactors, by correction of the reactant ratio shown in this chapter can be extended to fed-batch reactors. However, for non-reversible reactions the concentration control of product, as the batch progresses requires the translation of the controlled variable because the product concentration response is only in one direction. A translation to a rate of change of product concentration; slope of the batch product concentration profile provides a controlled variable that can increase and decrease based on feedback action. The computation provides an indication of product formation rate and yield and enables a prediction of batch endpoint.

Insight: Reactant concentration control systems for continuous liquid reactors can be extended to fed-batch reactors. However, product concentration control of non-reversible reactions requires a translation of the controlled variable to be the product concentration profile slope.

Analyzers and inferential measurements can provide composition control to correct the ratio of reactants. The lead reactant flow controller setpoint is multiplied by a ratio factor and added to the composition controller output. The setpoint is used instead of the actual flow measurement to reduce noise from the process and sensor (e.g. pressure and velocity profile fluctuations in differential head meters) and cycling from valve backlash or stick-slip and to enable better timing of the flow adjustments for production rate changes. However, the valve must be able to reach the flow setpoint by proper valve sizing and a valve design that prevents the valve from getting stuck or plugged. The reactant flow controllers are tuned for the same closed loop time constant to eliminate transient unbalances in the stoichiometric ratio of reactants added. A feedforward summer is used because both the process gain and the process time constant have an inverse relationship to reactant flow. Since the maximum controller gain is proportional to the ratio of process time constant to process gain, the effect of flow cancels out in the PID tuning.

At-line analyzers can be multiplexed with automated sample systems so one analyzer can service several reactors to help justify the cost. Inferential measurements can make the concentration measurement faster and smoother and less susceptible to missing or spurious results and noise. Inferential measurements except possibly for those from Coriolis meters must be periodically corrected by analyzer measurements ideally in the process but possibly in the lab. An enhanced PID is used in the composition loop to prevent excessive reset action and cycling from the large sample time and analyzer cycle time of at-line analyzers.

Insight: Analyzers and inferential measurements can provide concentration control to correct the ratio of reactants to account for unknowns in the reactants and reaction chemistry.

Insight: Inferential measurements can provide smoother and faster concentration measurements but do not eliminate the need for analyzers somewhere except for those measurements based on Coriolis meters.

Well-mixed single phase liquid reactors can achieve tight composition control by tight temperature and composition control. Accurate measurement and tight ratio control of reactants is critical. For continuous reactors tight level control is also important for slow reactions with a setpoint adjusted based on production rate to keep the residence time constant.