This is an excerpt from the November/December 2013 issue of InTech magazine by Ehren Kiker, a product manager with Endress+Hauser. To read the full article, please see the link at the bottom of this post.

Thermocouples (TCs) and resistance temperature detectors (RTDs) are the most widely used temperature sensors in automation and process control. They are found embedded in motors, valves, turbines, bearings, and a host of other devices. Most smart instruments such as flowmeters, pressure transmitters, and level transmitters also have an embedded temperature sensor-used to correct the primary measured variable or for process control.

When used alone, temperature sensors are often installed in thermowells, which are inserted into tanks, vessels, and pipes. A thermowell protects the sensor from the environment, but it slows the response time and degrades the accuracy. Installing sensors in a thermowell is a different subject, and will not be covered here. Instead, this article discusses direct immersion sensors; i.e., TCs and RTDs that are directly inserted and exposed to the process without the protection of a thermowell.

Theories of Operation

A thermocouple consists of two wires of dissimilar metals, joined at both ends-at the reference point outside the process (cold junction) and at a junction at the point of measurement (hot junction). The metals react differently to temperature changes and generate an electromotive force (EMF) voltage based on the temperature differential between the junctions (the Seebeck effect). A resistance temperature detector is based on the principle that electrical resistance in a wire increases with temperature.

In both cases, the sensor is wired to a transducer or signal conditioner that has been calibrated to accept the input voltage or resistance, calculate the correct temperature, and output it as a 4-20 mA, mV, or digital signal to an automation system.

The above is pretty basic, taught in every Instrumentation 101 class. But it poses the first question to consider when choosing a sensor: How do you wire the sensor to the transducer, signal conditioner, or automation system? Such devices and systems, being electronic in nature, need to be mounted in a reasonably safe location, away from high temperatures.

TCs must be wired with thermocouple extension wire, which is the same as the wire used in the TC. For example, a Type K TC uses a wire of nickel-chromium connected at the sensing junction to a wire of nickel-alumel. Extension wire must be the same composition, that is, one nickel-chromium and one nickel-alumel wire. In general, longer runs of extension wire are discouraged, as the wires act as an antenna, making the measurement more susceptible to electromagnetic and radio frequency interference. Cost may also be an issue when dealing with long extension wires, especially ones with exotic materials (e.g., Type R TCs). In certain cases, a compensation cable made up of a less expensive material with similar EMF properties to the TC can be used.

RTDs, on the other hand, can be wired with standard cable for much longer distances; however, they are typically limited by issues related to self-heating errors. In both cases, the extension wiring must be shielded against electrical noise in the plant. Note that TC extension wire is more susceptible to noise than RTD cable.

Sensor construction

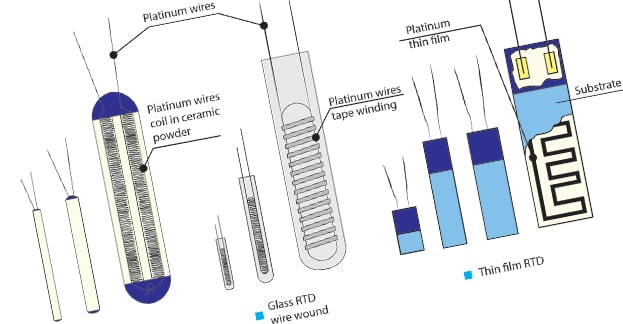

A wire-wound RTD consists of fine coiled wire wrapped around a ceramic or glass element, then placed in a sheathed probe for protection (see figure 1). Thin-film RTDs have a platinum coating over a ceramic substrate. Thin-film RTDs are not as susceptible to vibration as wire-wound RTDs but typically are more limited in their applicable temperature range.

Wire-wound RTDs are typically made from copper, nickel, or platinum alloys. Platinum is the most popular, because it has better accuracy and works over a wider temperature range. RTDs can be taped or cemented to a surface, mounted in a probe, or embedded in a device via threaded holes.

Thermocouples are not as fragile as RTDs, and are typically protected by a metal covering that can be bolted, welded, soldered, or glued to a surface. In some cases, the temperature junction can be left exposed to the environment, allowing for faster response times (see figure 2).

Grounding can be an issue. A TC can build up a static charge that affects its accuracy, so it may need to be grounded. However, TCs can also pick up circuit noise when grounded to an electrical device or machine. Determining whether or not to ground a TC depends on specifics of the particular application, such as the amount of electrical noise present in the measurement environment and the grounding circuit.

Nasty environments

Temperature sensing is often done in “unfriendly” environments, such as corrosive, oxidizing, or reducing atmospheres, often accompanied by severe vibration and electrical noise. When selecting an RTD or TC, the environment must be taken into account. If the process environment poses a high degree of risk of sensor failure, a thermowell made of a material that is suitable for the process environment should be considered.

Vibration-Wire-wound RTDs are most susceptible to vibration. Wire-wound RTDs can fail from mechanical stress in high-vibration applications and should not be used. Thin-film RTDs have a higher tolerance for vibration, but they are not as good as TCs, which have the highest resistance to vibration.

Electrical noise-As noted above, the extension wires for both RTDs and TCs are susceptible to electrical noise. In high-noise environments, extension wires should be sheathed, shielded, grounded, and kept as short as possible. An RTD is a better choice in high-noise environments.

Harsh environments-When dealing with a harsh environment, check to see if the RTD or TC sensor manufacturer offers protection against adverse conditions. Wire-wound RTDs in their protective casings are quite rugged and immune to most environmental problems. For additional protection, RTDs can be coated with perfluoroalkoxy (PFA) polytetrafluoroethylene for use in plating baths, highly pressurized systems, or similar applications. RTD extension wires are available with polyvinyl chloride, PFA, or fiberglass insulation for protection.

TCs, especially those with metal cases, are much more rugged than RTDs and better able to deal with corrosive or oxidizing atmospheres. When exposed TC junctions are used, special care must be taken in harsh environments.

TCs are classified by type, i.e., Types E, J, K, N, T, S, R, and B. Each type is suitable for a specific temperature range from -201°C to 1700°C, and the construction of each makes it suitable for use in various environments:

- Type E: suitable for vacuum, inert, mildly oxidizing, or reducing atmospheres

- Type J: may be used, exposed or unexposed, where there is a deficiency of free oxygen

- Type K: typically requires metal or ceramic protection

- Type N: resists oxidation where sulfur is present

- Type T: can be used in either oxidizing or reducing atmospheres

- Types S, R, B: should always be protected with a ceramic tube, a secondary tube of porcelain, and a silicon carbide or metal outer tube as conditions require

Other considerations

Measuring range: RTDs can measure temperatures up to 1000°C, but it can be difficult to get accurate measurements from an RTD at temperatures above 400°C. TCs can measure up to 1700°C. The generally accepted rule is: for temperatures below 850°C, use an RTD for accuracy; for temperatures above 850°C, use a TC. Industrial measurements typically are 200°C to 400°C, so an RTD may be the best choice in that range.

Response time: While both sensors respond quickly to temperature changes, TCs are faster. In certain cases, however, manufacturing processes allow for production of thin-film RTDs with greatly improved response times.

Dimensions: Both sensors are fairly small, at about 0.5 mm diameter. If space is an issue for mounting a sensor, check with the supplier for size and mounting options.

Vibration: In general, TCs are less susceptible to vibration than RTDs. However, in certain manufacturing processes thin-film RTDs can be produced that are capable of much greater vibration resistance than standard RTDs.

Self-heating: An RTD is made of very fine wires or very fine coatings, and requires a voltage from a power supply-TCs do not require power. Although the power required is only 1 mA to 10 mA, it can cause the platinum element in the RTD to “heat up,” thus affecting accuracy of the measurement. If long extension wires are used, more power may be needed to overcome resistance in the wires, thus increasing the self-heating problem.

Stability: The long-term stability of an RTD is very good, meaning that its readings will be repeatable and stable for a long time. TCs, on the other hand, tend to drift. The EMF produced by a TC can change over time because of oxidation, corrosion, and other changes in the metallurgical properties of the sensing elements. TC drift is irreversible, and some provision is needed to detect it, such as software or testing for loop resistance.

Accuracy: As a general rule, RTDs are more accurate than TCs. RTDs can produce accuracy of 0.1C, while TCs are typically accurate to only 1C.

Although not a technical issue, TCs are considerably less expensive than RTDs due primarily to lower production costs. Depending on the number of sensors needed for a particular application, this could be a major factor.

Careful selection of the right temperature sensing technology is essential to ensure the best performance, reliability, and cost effectiveness. Suppliers that sell both TCs and RTDs are often good sources of information when deciding which type of sensor to use, as is previous experience with different sensor types in various applications.

About the Author

Ehren Kiker is a product manager with Endress+Hauser with more than 15 years of experience in process control instrumentation. Contact Ehren at: ehren.kiker@us.endress.com.

[/dropshadowbox]