Before we start, I have a few questions for my readers: Are we going to our customers and seeing how much they are comfortable or satisfied with our recently completed projects? Are they facing any challenges on these projects? The reason I ask is because I have worked for many years as an end user, and I can say that I have not seen any vendor come to me for this purpose. Of course, they come to me to see if any new projects are in the pipeline. What exactly is going wrong? We should always think about our customers first, because if the customers are happy, we as vendors are happy, and we should treat projects like our children and take care of them.

To end users, do you know how well your plant is running in real-time? Are you really making money? Answer yourself now:

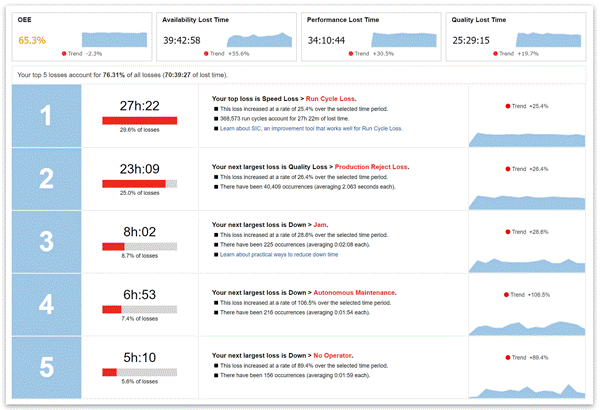

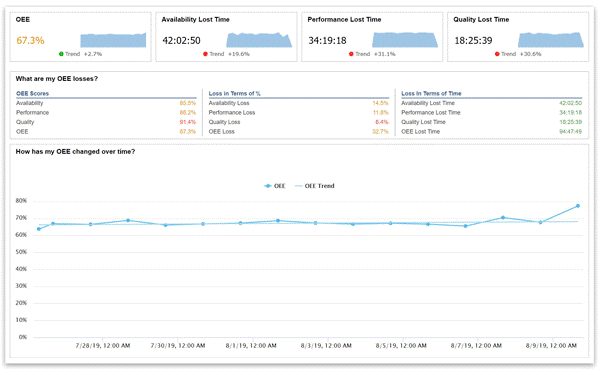

- Do you have an ongoing Overall Equipment Effectiveness (OEE) score for each process?

- Do you know why you should know your process OEE?

- Is performance based on validated ideal cycle times?

- Do you have an active incremental improvement target for OEE?

- Is your OEE measurement and data collection automated?

- Has the process constraint been identified?

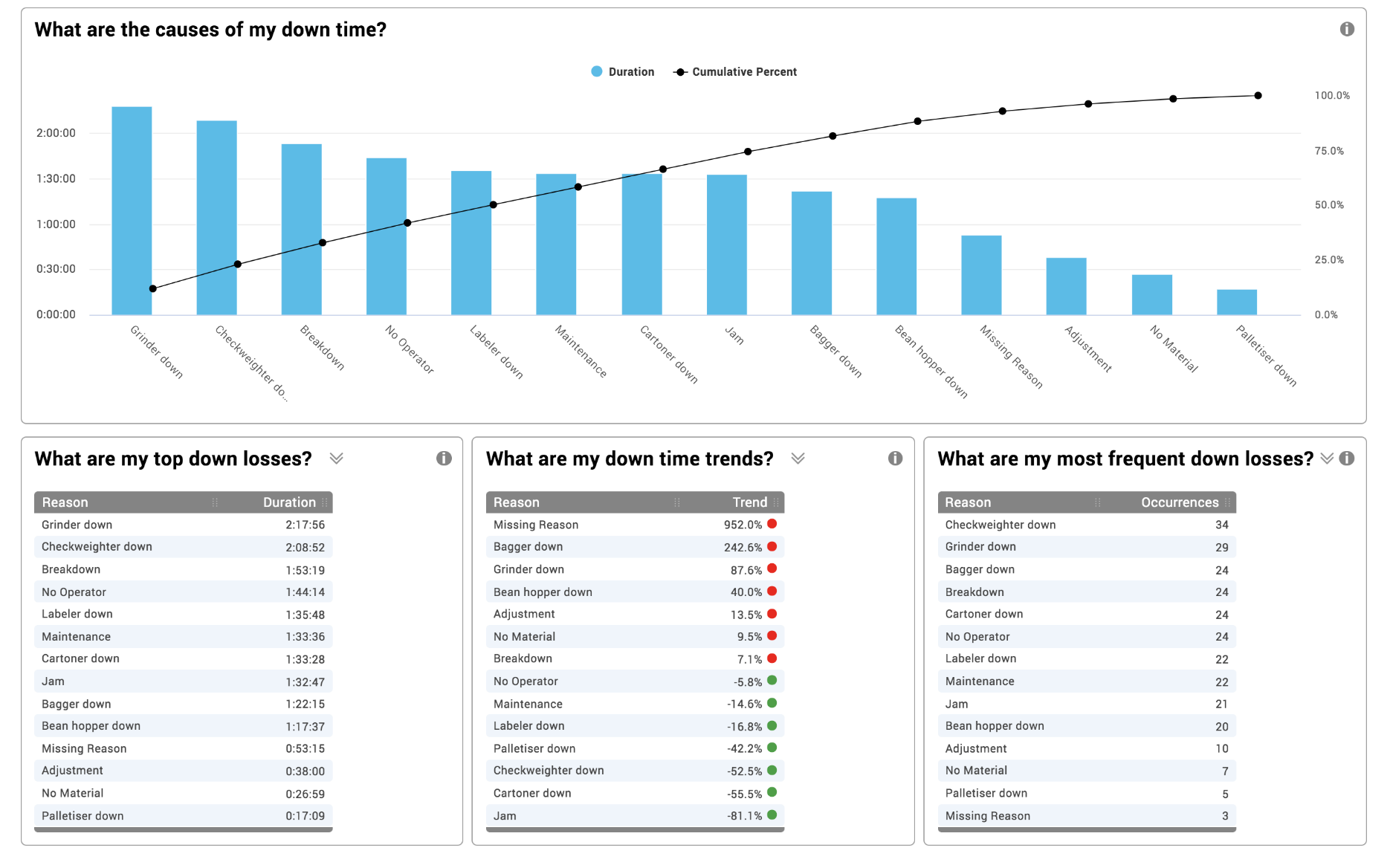

- Are reasons and duration captured for all downtime?

- Are we on track to hit our production goal today?

- Is each downtime incident evaluated for a quick fix?

- Do you have hour-by-hour production?

If you’ve answered “no” to any of these questions, then I would strongly recommend an Industrial Internet of Things (IIoT) system in your plant.

Now my final question is: For some of the big companies who get projects from end users due to their name, how much do they keep their promise on implementation once they have been awarded the project? My experience is that using buzzwords for end users is becoming very common. Whether we want to hear buzzwords or we want to see projects get implemented as per our customer’s expectations, we know that almost every customer is looking for a quick return of their investment. They can’t wait 3 to 4 years. We should always give solutions to our customer for ROI no more than 6 months’ time.

Imagine data coming to us in real-time where we know our exact production rates at any given second. What if we could remotely monitor the status of our equipment or production lines and process from anywhere? Or get instant alerts on our mobile phones when there is a problem on the production line? What if we could collect critical production data to track and improve long-term performance trends? What if we no longer needed manual data entered an Excel sheet? Even our clients will ask for automated values for more transparency.

IIoT will help leverage data throughout the factory in more meaningful and profitable ways and optimize operations in the long-term by tracking OEE. End-to-end IIoT will solve all real-time challenges on the factory floor by making better analyses, data-driven decisions, and increase overall efficiency.

We should always provide our customer IIoT with some of the following features:

- No programming, due to time and cost

- No software to install

- No servers to maintain

- Free cloud services

- Easy installation

- No recurring fees

- No contracts

- Unlimited users

- Free software updates

Here is the fascinating and extremely important fact: Most equipment is not used anywhere near its true capacity. In fact, the difference between typical manufacturing (an OEE score of 60%) and best-in-class manufacturing (an OEE score of 85%) represents an astounding 41.6% increase in capacity.

Here is the fascinating and extremely important fact: Most equipment is not used anywhere near its true capacity. In fact, the difference between typical manufacturing (an OEE score of 60%) and best-in-class manufacturing (an OEE score of 85%) represents an astounding 41.6% increase in capacity.

So, before thinking about adding shifts, overtime, outsourcing, or purchasing new equipment, we should make sure that we truly understand and consider the untapped potential that exists in current factories. OEE is a well-established performance metric that considers equipment losses (usually broken into Availability Loss, Performance Loss, and Quality Loss, and further broken into the Six Big Losses, as shown below). OEE measures performance with respect to planned production time (the percentage of planned production time that is fully productive).

Leveraging the Six Big Losses

Leveraging the Six Big Losses

A comprehensive and very practical way to address equipment losses is through the underlying Six Big Losses. The Six Big Losses are very well-aligned to discrete manufacturing and map to specific improvement tools and countermeasures.

The Six Big Losses are:

- Setups and Adjustments (Planned Stops)

- Breakdowns (Unplanned Stops)

- Reduced Speed (Slow Cycles)

- Small Stops

- Production Rejects

- Start-up Rejects

Improving manufacturing productivity leads to a “virtuous cycle” of increased capacity. More efficient equipment can be scheduled more accurately and for smaller lot sizes. This lowers cost and reduces lead times, which leads to more customer orders which utilize the increased capacity.