Sound is such a common part of everyday life that we rarely appreciate all of its functions. It provides enjoyable experiences such as listening to music, enables spoken communication, and it can alert or warn us. Sound also permits us to make quality evaluations and diagnoses—the chattering of car valves, a squeaking wheel, or a heart murmur.

Why Do We Measure Sound?

Measurements provide definite quantities, which describe and rate sounds. The measurements give us an objective means of comparing annoying sounds under different conditions. Sound measurements also give a clear indication of when a sound may cause damage to hearing and permit corrective measures to be taken.

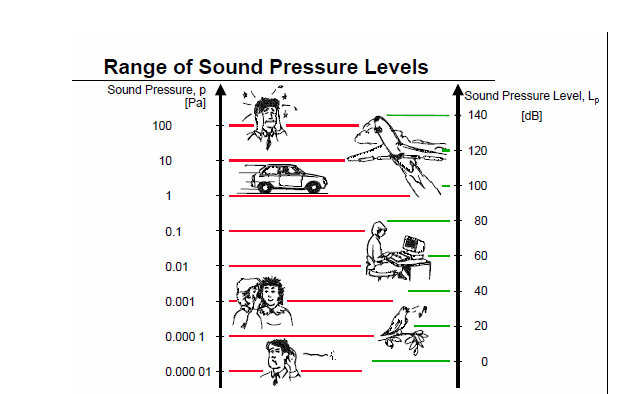

The measurement and analysis of sound is a powerful diagnostic tool in noise reduction programs. It is a tool which can help to improve the quality of our lives. The second main quantity used to describe a sound is the size or amplitude of the pressure fluctuations. The weakest sound a healthy human ear can detect has an amplitude of 20 millionths of a Pascal (20 μPa)—some 500,000,0000 times less than normal atmospheric pressure. Thus, if we measured sound in Pa, we would end up with some quite large, unmanageable numbers.

To avoid this, another scale is used—the decibel or dB scale. One useful aspect of the decibel scale is that it gives a much better approximation to the human perception of relative loudness than the Pascal scale. This is because the ear reacts to a logarithmic change in level, which corresponds to the decibel scale where 1 dB is the same relative change everywhere on the scale. The measurement of sound is done using measurement microphones, a calibrated microphone used in system for measuring sound. The reason for the high degree of acceptance is that the condenser microphone has the following properties which are essential for a standard transducer:

The measurement of sound is done using measurement microphones, a calibrated microphone used in system for measuring sound. The reason for the high degree of acceptance is that the condenser microphone has the following properties which are essential for a standard transducer:

- High stability under various environmental conditions

- Flat frequency response over a wide frequency range

- Low distortion

- Very low internal noise

- Wide dynamic range

- High sensitivity

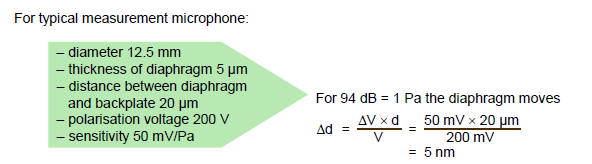

How Much Does the Diaphragm Move?

This infinitesimal movement requires the highest of precision in manufacturing and selection of material. To attain the microphone’s high standard, considerable care is required in both design and production. This includes advanced clean-room techniques, very tight mechanical tolerances, a special diaphragm construction, and artificial aging techniques.

This infinitesimal movement requires the highest of precision in manufacturing and selection of material. To attain the microphone’s high standard, considerable care is required in both design and production. This includes advanced clean-room techniques, very tight mechanical tolerances, a special diaphragm construction, and artificial aging techniques.

Measurement microphones are based on a very simple physical principle: Capacitance. The capacity of a microphone is inversely proportional to the distance between the backplate (a stiff plate), and the diaphragm (a thin, highly tensioned metal foil). When exposed to sound pressure, the diaphragm deforms and moves closer to or further away from the backplate, changing the capacity of the system. These variations in capacitance are converted to voltage variation. Most measurement microphones are based on this principle.

Microphones are primarily of two types:

- Polarized: These need a DC Voltage across the diaphragm to back plate the air gap to fix the charge and therefore require an external voltage power supply.

- Prepolarized: These require no external polarization voltage; the charge is fixed by a thin layer of charge holding electrets.

Microphone selection is based also on the frequency and level (db) to be measured. The selection is based on the diaphragm diameter and the typical standards are 1” ½”, ¼”, or 1/8”. The smaller the diaphragm, the higher the frequency and dynamic range.

After the measurement of the sound, frequency analysis is typically carried out using octave analysis. Octave analysis filters the signal and measures the energy at the output to provide useful frequency information. While sound pressure can measure the amount of noise that is emitted, it varies based on the ambient conditions. Therefore, to ensure standardization, sound power is calculated.

Sound power is a calculated quantity and is either calculated using sound pressure levels as per standards like ISO 3744 and ISO 3745, or by intensity as per standards like ISO 9614. Another fascinating topic is sound quality, which qualifies perception with measured quantities. Acoustics as the study of sound is another fascinating topic and has evolved over the years, taking advantage of new measurement techniques and technology development which has made measurements both faster and more accurate, and at the same time lead to miniaturization of the instruments.