This post was authored by Kevin Klustner, executive director at the Center for Advanced Materials and Clean Energy Technologies (CAMCET) at the University of Washington, and former CEO of Powerit Solutions (acquired by Customized Energy Solutions).

Most energy-intensive businesses think of electrical bills as a cost that must be borne, rather than one that can be managed. Efforts to improve business sustainability are changing this, but they tend to focus only on part of the equation: improving energy efficiency.

With advanced demand management automation technology, businesses can do much more than that; they can connect to the smart grid and save money on electricity while contributing to grid stability and helping to eliminate the need for more power plants. Even businesses with complex, demanding production processes can cut energy costs without compromising production or quality – improving profit margins and freeing up the budget for other automation needs.

The key is to take full advantage of a suite of demand management strategies: demand control, demand response, and dynamic pricing optimization. Technology providing the most sophisticated analytic capabilities allows businesses to then refine each of these strategies by drilling down into the performance of specific loads, comparing current and historical data, and viewing data across the enterprise.

Demand management strategies defined and decoded

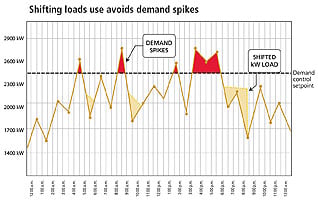

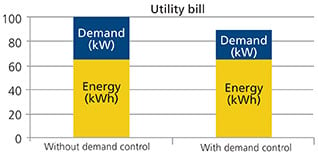

Demand control: In addition to paying for the amount of energy they use (measured in kWh), many energy-intensive businesses pay a demand charge based on the peak rate of electrical flow during a billing cycle, measured in kilowatts (kW). This is usually the highest usage during a 15-minute period. The business pays for kWh, plus peak usage, multiplied by a rate for demand. Demand control (DC) involves preventing demand spikes, rooting out inefficiencies, and shifting power demand to the lowest-rate periods.

An advanced demand management system (DMS) allows you to do this safely and reliably by automating strategic demand reductions over a collection of loads while maintaining productivity. It can prioritize loads sequentially, by group, or by other factors, and it can orchestrate load shedding to achieve both savings and productivity targets. This level of control and precision is impossible for most facilities to achieve manually or with disparate automation systems. Actions the DMS might take for an industrial business include:

- Slowing down or cycling fans and blowers (or raising the temperature setpoint in a cooled area) to reduce kilowatt load from exhaust fans, refrigeration compressors, and condensers.

- Applying slight changes in suction pressure to reduce the load from refrigeration compressor motors.

- Curtailing nitrogen system compressor motors.

- Reducing wastewater treatment loads to minimize energy consumption by blowers, agitators, and pumps.

- Shutting down battery chargers.

- Delaying the start of vacuum tubes or grinder.

The savings can be significant: peak-time energy use can account for as much as 40 percent of an industrial user’s electricity bill; avoiding these spikes can reduce the overall bill by as much as 15 percent.

Demand control in action: kW use is simply shifted or slightly delayed, lowering peak kW while not affecting facility productivity based on total kWh.

Demand control in action: kW use is simply shifted or slightly delayed, lowering peak kW while not affecting facility productivity based on total kWh.

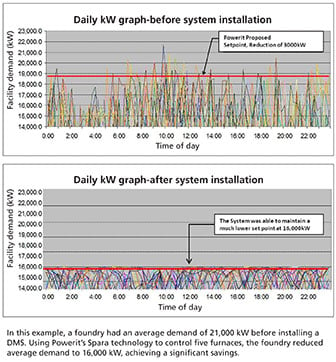

For example, at Mission Produce in Oxnard, Calif., the DMS controls evaporator and condenser fans via variable frequency drives (VFDs), five refrigeration compressors in two locations, and battery chargers. Since system implementation, Mission Produce has reduced its peak-load energy use and monthly energy bills by about one-third. The company has set rules in the system to protect production - the DMS never takes curtailment actions beyond the levels specified. Rochester Metal Products in Rochester, Ind., had an average demand of 21,000 kW before installing a DMS. Using a DMS to control five furnaces and working in stages to ensure there was no loss in production, the foundry reduced average demand to 16,000 kW, achieving a significant savings.

Utilities typically bill a peak demand charge based on highest average kW during a set time interval. This charge typically is 10 to 40 percent of the bill. Demand control can reduce demand charges 10 to 30 percent, which cuts the overall utility bill 5 to 10 percent.

Utilities typically bill a peak demand charge based on highest average kW during a set time interval. This charge typically is 10 to 40 percent of the bill. Demand control can reduce demand charges 10 to 30 percent, which cuts the overall utility bill 5 to 10 percent.

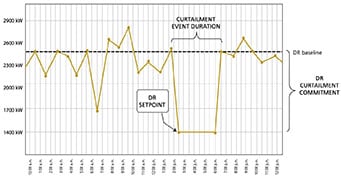

Demand response: Utilities and power system operators across the country are implementing demand response (DR) programs to relieve stress on the grid and reduce the need to build new power plants. DR programs pay electricity users to reduce consumption on demand at times to be determined, typically when the utility or power system operator is experiencing spikes in power demand. For example, on an unusually hot summer day, with air conditioners running full blast and causing a demand spike, a utility might call on DR participants to reduce their usage by an amount specified in their contract. There are numerous types of DR programs, with varying names and requirements. To understand the opportunities they offer and needs they fulfill from a business perspective, it is useful to group them into two main categories:

- Standby/reliability: Energy users commit in advance to making specific load reductions when the grid is stressed. These infrequent events often last two to four hours. Prices are usually $30,000 to $60,000 per megawatt.

- Reserves/market-based: Instead of committing in advance to reducing power usage by a certain number of kilowatts, as with standby/reliability programs, energy users agree to cut usage based on a set price. With reserves/market-based programs, the user can decide daily or on shorter notice whether to participate. Events are more frequent than standby/reliability events and usually last one hour or less. Prices are typically about $40,000 per megawatt.

A utility or power system operator may offer a variation of one or both types of DR programs. Variations that require automated demand response (Auto-DR) tend to be the most lucrative. In these programs, a business's system and the utility or grid operator's system "talk" with each other using a standard, such as Open Automated Demand Response (OpenADR), with a Smart Demand Response Automation Server (Smart DRAS) client providing a dynamic connection. The utility's system notifies the user's system of a DR event, and the user's system takes action according to the energy usage rules set for that facility.

In this example, a foundry had an average demand of 21,000 kW before installing a DMS.

In this example, a foundry had an average demand of 21,000 kW before installing a DMS.

One Northeast foundry operation is earning over $130,000 a year from two facilities participation in the regional grid operator's synchronous reserves program. The program is tricky: participants get only 10 minutes notice of each 30-minute event, and in that 10 minutes, they must reduce their load by the amount of power they bid into the market. The more they bid, the more they earn. But these events can happen several times a week, and the program runs around the clock. Participation is practical for the foundry because of its DMS. Plant managers load a schedule in the system, and when the grid operator calls an event the DMS checks to see if the foundry is in the market at that time. If it is, the system takes load-shedding actions to lower the plant's kilowatts to the prescribed amount. When the event is over, the DMA releases control of the furnaces, and they go back to full power.

The two foundry facilities together are also earning over $35,000 annually from participation in a more traditional interruptible load DR program and saving more than $76,000 a year through DC. Many businesses participate in DR programs through aggregators (also known as curtailment service providers, or CSPs), third-party contractors that serve as intermediaries between energy users and utilities or system operators. Aggregators combine curtailment potential from many power customers and guarantee that a large total amount will be available for reduction or interruption.

They develop their own DR programs, giving energy users more DR options, as well as a steady stream of DR payments. In many cases, participants in an aggregator DR program can use software supplied by the aggregator to identify energy-saving opportunities. But most energy-intensive businesses need an advanced DMS to obtain maximum benefit from aggregator programs because the DMS integrates with existing controls and enables automated responses. Manual responses are cumbersome and do not allow participation in the latest programs.

Dynamic pricing optimization: Many utilities employ dynamic pricing strategies, such as real-time pricing (RTP), that involve rate changes based on the market price of electricity, weather events, or other conditions. These changes can happen with notice ranging from just minutes to 24 hours. For participants in an RTP program, much of the time the rates are 20 to 40 percent lower, but peak rates can be astronomical - for short periods, as high as 100 times the usual rate.

An advanced DMS lets businesses respond automatically to ongoing price fluctuations by shifting consumption to lower rate periods or reducing consumption during costly super-peak times. For instance, a food processing plant participating in RTP might drop the temperature of a cooler lower than necessary during low-cost times, and then shut it down and allow it to come back up to the usual temperature during peak hours, conserving energy when the rates are high.

During a demand response (DR) event, an advanced DMS can automatically shed loads based on preset parameters, allowing the facility to earn DR payments while maintaining essential production capacity.

During a demand response (DR) event, an advanced DMS can automatically shed loads based on preset parameters, allowing the facility to earn DR payments while maintaining essential production capacity.

Case study: integrated energy demand management

Each major load-shedding strategy - DC, DR, and dynamic pricing, along with energy efficiency - has effects and requirements that make it a better match for some types of businesses than for others. Most energy-intensive businesses, however, will gain maximum control over and benefits from an integrated demand management strategy that involves two or more approaches. Case in point: Four Star Fruit of Delano, Calif., uses an advanced DMS to implement DC, Auto-DR, and energy efficiency measures that, combined, are saving the company 16 percent annually on its electricity bill. Four Star uses a very large amount of electricity during three critical months of the year, and its business is growing. In the 36 months preceding the implementation of its DMS, the business grew in the double digits while its power consumption doubled.

The company wanted to better control its energy use in light of a predicted rise in power prices over the next several years, as well as improve its sustainability credentials. Facilities like Four Star's offer good potential for both DR and DC strategies: the facility can precool and flywheel-cool in anticipation of a DR event, or use temperature buffers to ride out a DC event. In this case, Four Star can:

- Combine precooling rooms and long-term storage rooms to provide balanced loads.

- Load precooling rooms with produce all day, and then precool them in the evening.

- Flywheel long-term storage rooms, cooling them in advance and powering down their refrigeration when precooling needs occur.

This type of facility (cold long-term storage) made Four Star a good candidate for an Auto-DR program. Four Star's DMS integrates with DR automation servers operated by its utility (Southern California Edison) and DR aggregator (EnerNOC). The company has successfully participated in DR events, achieving a load reduction near its test demonstration reduction of 700 kW.

Advanced energy demand management at work

Most plant managers, and even automation specialists, have a hard time envisioning how the complex operations at their facility could really be controlled for energy savings without disrupting production. To illustrate how it works, here is an example of a typical DC operation at a food processing facility:

- The system's real-time algorithm predicts that the facility's current energy use will exceed its setpoint by x kW. The facility needs to shed load.

- The system determines which refrigeration compressors are enabled for reduction at this moment. These loads are available for curtailment.

- The system stages curtailment actions based on a preferred order that has been set in the system. Compressor A and Compressor B have a priority of 1 and 2. Compressor A has x kW available for reduction, so the system powers it down accordingly. It then powers Compressor B down x kW to get the remaining reduction needed.

- Each compressor can operate at reduced power for only so long without disrupting operations, and that time has been plugged into the system. The system monitors the reduction time and sees that Compressor A has hit that point. It releases Compressor A and further reduces Compressor B to get the rest of reduction needed.Note: Time as a constraint is a simple example of a rule that can be integrated into the system's decision-making process. Rules can also be complicated and logic-based (if pump speed is x and tank level is y, then the agitator can be curtailed to speed z) or triggered by schedules or production factors.

- Once the reduction goal is hit, the system releases all loads according to the procedure set by the facility.

The key point is that while the control operation manipulated the facility's processes to meet energy usage goals, it did not affect production. The changes were defined in advance as acceptable power reductions in return for energy savings.

Assessment: determining your facility's savings potential

Follow this four-step process when assessing the energy savings potential of any given facility:

- Define the savings opportunities. Analyze electric bills and historical kilowatt interval data, and evaluate opportunities to participate in DR or other incentive programs. (This analysis may be accomplished remotely by accessing metering data.)

- Create a data picture of the facility. Collect detailed data about the facility's main processes and largest electrical loads, and about the facility in general.

- Perform a site audit. The audit covers the entire facility and all processes, from receiving raw materials to final product shipping. Because the largest electrical loads provide the best ROI for automation investment, those loads should be analyzed in detail. Review current standard operating procedures, typical run time, time of use, and loads, and evaluate those areas for inefficiencies.

- Savings can come from multiple initiatives. In general, if a load has a process buffer (the output must be kept between a specified minimum and maximum level, or within a temperature range), that can be used to balance the facility's peak demand. The load can be turned off or slowed down when energy costs are high. By studying the entire process and identifying these buffers within batch or continuous processes, opportunities can be typically found for energy cost reductions via DC, DR, dynamic pricing, energy efficiency, or all four.

- Finalize the evaluation. Based on the results of data collection and the site audit, revise the initial savings estimate to correct any mistaken assumptions and reflect actual savings potential.

Assessing a DMS

Key features of the most effective energy DMS are:

- Ability to take control of the loads - within parameters you set - so that no human intervention is required.

- Seamless integration with existing systems and the ability to extend their functionality.

- Capacity to connect with many loads in order to take maximum advantage of potential savings.

- Access to real-time data from your equipment in order to analyze and predict demand spikes.

- A smart grid connection to your electricity provider and aggregator or ISO to receive event notifications.

- Rules-driven, process-protecting routines, tailored to your operations that can manage an infinite variety of industrial processes, limitations, and thresholds.

- Visualization and analysis tools that pull the data streams together and provide a comprehensive view of energy usage across the enterprise, as well as a window into the performance of specific loads.

- Ability to track and calculate peak demand based on your bill.

- Ability to manage different business scenarios, including time-of-use rate schedules, DR events, and real-time pricing.

- Insight into the facility's full energy use, not just production loads.

With advanced demand management technology used strategically, energy-intensive businesses can significantly reduce previously uncontrollable energy costs. And by aggressively managing a resource that will continue to rise in cost, you can increase your company's resilience and gain a competitive advantage.

About the Author

Kevin Klustner is executive director at the Center for Advanced Materials and Clean Energy Technologies (CAMCET) at the University of Washington. He formerly was CEO of Powerit Solutions, a Seattle-based international cleantech company that focused on advanced demand management technology. Powerit was acquired by Customized Energy Solutions. Kevin is the author of Energy Efficiency: The Future Is Now.

A version of this article also was published at InTech magazine.