The following technical discussion is part of an occasional series showcasing the ISA Mentor Program, authored by Greg McMillan, industry consultant, author of numerous process control books, 2010 ISA Life Achievement Award recipient and retired Senior Fellow from Solutia Inc. (now Eastman Chemical). Greg will be posting questions and responses from the ISA Mentor Program, with contributions from program participants.

In the ISA Mentor Program, I am providing guidance for extremely talented individuals from countries such as Argentina, Brazil, Malaysia, Mexico, Saudi Arabia, and the USA. This question comes from Caroline Cisneros.

Negative resistance also known as positive feedback can cause processes to jump, accelerate and oscillate confusing the control system and the operator. These are characterized as open loop unstable processes. Not properly addressing these situations can result in equipment damage and plant shutdowns besides the loss of process efficiency. Here we first develop a fundamental understanding of the causes and then quickly move on to the solutions to keep the process safe and productive.

Caroline Cisneros, a recent graduate of the University of Texas who became a protégé about a year ago, is gaining significant experience working with some of the best process control engineers in an advanced control applications group. Caroline asks a question about the dynamics that cause unstable processes. The deeper understanding gained as to the sources of instability can lead to process and control system solutions to minimize risk and to increase process performance.

Caroline Cisneros’ Question

What causes processes to be unstable when controllers are in manual?

Greg McMillan’s Answer

Fortunately, most processes are self-regulating by virtue of having negative feedback that provides a resistance to excursions (e.g., flow, liquid pressure, and continuous composition and temperature). These processes come to a steady state when the controller is in manual. Somewhat less common are processes that have no feedback that will result in a ramp (e.g., batch composition and temperature, gas pressure and level). Fortunately, the ramp rate is quite slow except for gas pressure giving the operator time to intervene.

There are a few processes where the deviation from setpoint can accelerate when in manual due to positive feedback. These processes should never be left in manual. We can appreciate how positive feedback causes problems in sound systems (e.g., microphones too close to speakers). We can also appreciate from circuit theory how negative resistance and positive feedback would cause an acceleration of a change in current flow. We can turn this insight into an understanding of how a similar situation develops for compressor, steam-jet ejector, exothermic reactor and parallel heat exchanger control.

The compressor characteristic curves from the compressor manufacturer that are a plot of compressor pressure rise versus suction flow shows a curve of decreasing pressure rise for each speed or suction vane position whose slope magnitude increases as the suction flow increases in the normal operating region. The pressure rise consequently decreases more as the flow increases opposing additional increases in compressor flow creating a positive resistance to flow. Not commonly seen is that compressor characteristic curve slope to the left of the surge point becomes zero as you decrease flow, which denotes a point on the surge curve, and then as the flow decreases further, the pressure rise decreases causing a further decrease in compressor flow creating a negative resistance to a decrease in flow.

ISA Mentor Program

The ISA Mentor Program enables young professionals to access the wisdom and expertise of seasoned ISA members, and offers veteran ISA professionals the chance to share their wisdom and make a difference in someone’s career. Click this link to learn more about the ISA Mentor Program.

When the flow becomes negative, the slope reverses sign creating a positive resistance with a shape similar to that seen in the normal operating region to the right of the surge point. The compressor flow then increases to a positive flow at which point the slope reverses sign creating negative resistance. The compressor flow jumps in about 0.03 seconds from the start of negative resistance to some point of positive resistance. The result is a jump in 0.03 seconds to negative flow across the negative resistance, a slower transition along positive resistance to zero flow, than a jump in 0.03 seconds across the negative resistance to a positive flow well to the right of the surge curve. If the surge valve is not open far enough, the operating point walks about 0.5 to 0.75 seconds along the positive resistance to the surge point. The whole cycle repeats itself with an oscillation period of 1 to 2 seconds. If this seems confusing, don’t feel alone. The PID controller is confused as well.

Once a compressor gets into surge, the very rapid jumps and oscillations are too much for a conventional PID loop. Even a very fast measurement, PID execution rate and control valve response can’t deal with it alone. Consequently, the oscillation persists until an open loop backup activates and holds open the surge valves till the operating point is sustained well to the right of the surge curve for about 10 seconds at which point there is a bumpless transfer back to PID control. The solution is a very fast valve and PID working bumplessly with an open loop backup that detects a zero slope indicating an approach to surge or a rapid dip in flow indicating an actual surge. The operating point should always be kept well to the right of the surge point.

For much more on compressor surge control see the article Compressor surge control: Deeper understanding, simulation can eliminate instabilities.

The same shape but with much less of a dip in the compressor curve, sometimes occurs just to the right of the surge point. This local dip causes a jumping back and forth called buzzing. While the oscillation is much less severe than surge, the continual buzzing is disruptive to users.

A similar sort of dip in a curve occurs in a plot of pumping rate versus absolute pressure for a steam-jet ejector. The result is a jumping across the path of negative resistance. The solution here is a different operating pressure or nozzle design, or multiple jets to reduce the operating range so that operation to one side or the other of the dip can be assured.

Positive feedback occurs in exothermic reactors when the heat of reaction exceeds the cooling rate causing an accelerating rise in temperature that further increases the heat of reaction. The solution is to always insure the cooling rate is larger than the heat of reaction. However, in polymerization reactions the rate of reaction can accelerate so fast the cooling rate cannot be increased fast enough causing a shutdown or a severe oscillation. For safety and process performance, an aggressively tuned PID is essential where the time constants and dead time associated with heat transfer in cooling surface and thermowell and loop response are much less than the positive feedback time constant.

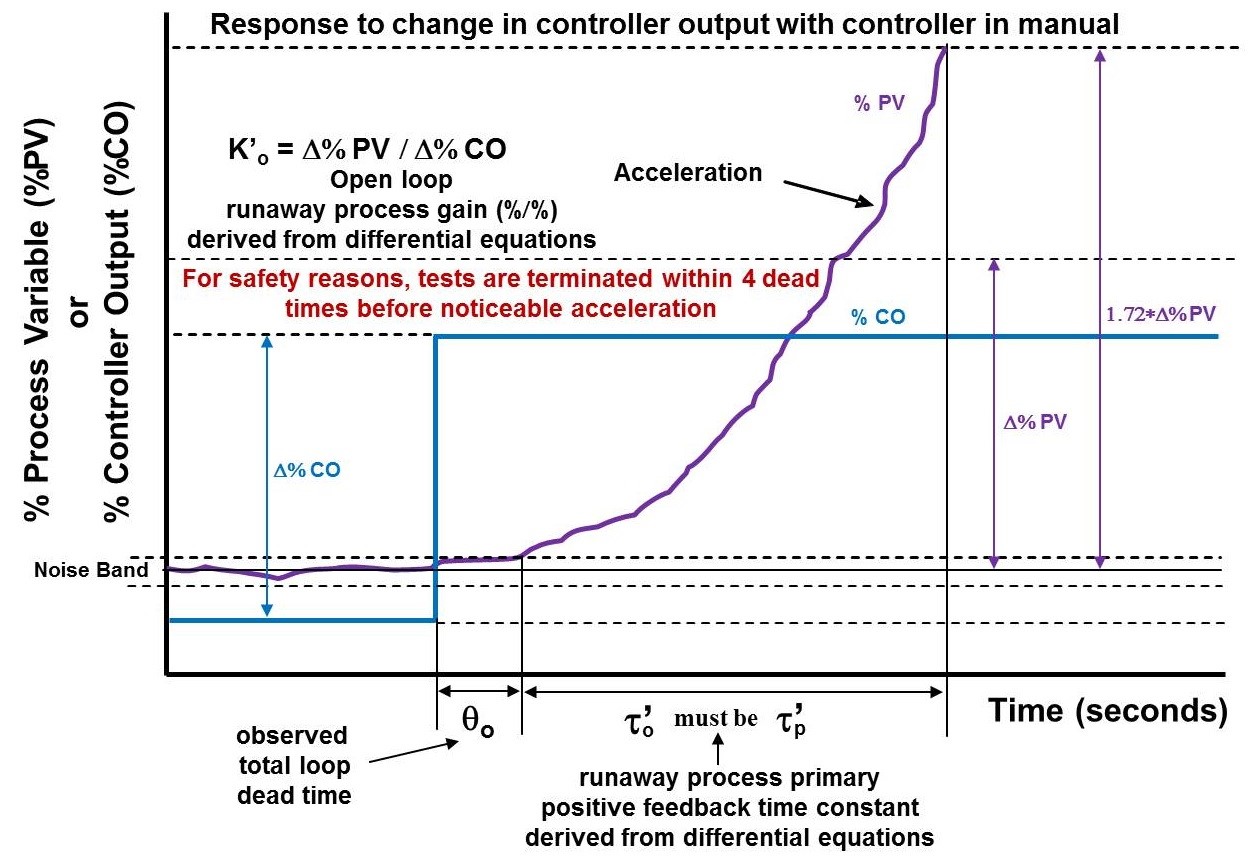

Derivative action must be maximized and integral action must be minimized. In some cases a proportional plus derivative controller is used. The runway response of such reactors is characterized by a positive feedback time constant as shown in Figure 1 for an open loop response. The positive feedback time constant is calculated from the ordinary differential equations for the energy balance as shown in Appendix F of 101 Tips for a Successful Automation Career. The point of acceleration cannot be measured in practice because it is unsafe to have the controller in manual. A PID gain too low will allow a reactor to runaway since the PID controller is not adding enough negative feedback. There is a window of allowable PID gains that closes as the time constants from heat transfer surface and thermowell and the total loop dead time approach the positive feedback time constant.

Figure 1: 1 Positive Feedback Process Open Loop Response

Figure 1: 1 Positive Feedback Process Open Loop Response

Positive feedback can also occur when parallel heat exchanges have a common process fluid input each with outlet temperature controller(s) with a setpoint close to the boiling point or temperature resulting in vaporization of a component in the process fluid. Each temperature controller is manipulating a utility stream providing heat input. The control system is stable if the process flow is exactly the same to all exchangers. However, a sudden reduction in one process flow causes overheating causing bubbles to form expanding back into the exchanger causing an increase in back pressure and hence a further decrease in process flow thru this hot exchanger.

The increasing back pressure eventually forces all of the process flow into the colder heat exchanger making it colder. The high velocity in the hot exchanger from boiling and vaporization causes vibration and possibly damage to any discontinuity in its path from slugs of water. When nearly all of the water is pushed out of the hot exchanger, its temperature drops drawing feed that was going to the cold heat exchanger that causes the hot exchanger to overheat repeating the whole cycle. The solution is separate flow controllers and pumps for all streams so that changes in the flow to one exchanger do not affect another and a lower temperature setpoint.

To summarize, to eliminate oscillations, the best solution is a process and equipment design that eliminates negative resistance and positive feedback. When this cannot provide the total solution, operating points may need to be restricted, loop dead time and thermowell time constant minimized and the controller gain increased with integral action decreased or suspended.

Additional Mentor Program Resources

See the ISA book 101 Tips for a Successful Automation Career that grew out of this Mentor Program to gain concise and practical advice. See the InTech magazine feature article Enabling new automation engineers for candid comments from some of the original program participants. See the Control Talk column How to effectively get engineering knowledge with the ISA Mentor Program protégée Keneisha Williams on the challenges faced by young engineers today, and the column How to succeed at career and project migration with protégé Bill Thomas on how to make the most out of yourself and your project. Providing discussion and answers besides Greg McMillan and co-founder of the program Hunter Vegas (project engineering manager at Wunderlich-Malec) are resources Mark Darby (principal consultant at CMiD Solutions), Brian Hrankowsky (consultant engineer at a major pharmaceutical company), Michel Ruel (executive director, engineering practice at BBA Inc.), Leah Ruder (director of global project engineering at the Midwest Engineering Center of Emerson Automation Solutions), Nick Sands (ISA Fellow and Manufacturing Technology Fellow at DuPont), Bart Propst (process control leader for the Ascend Performance Materials Chocolate Bayou plant), Angela Valdes (automation manager of the Toronto office for SNC-Lavalin), and Daniel Warren (senior instrumentation/electrical specialist at D.M.W. Instrumentation Consulting Services, Ltd.).

About the Author

Gregory K. McMillan, CAP, is a retired Senior Fellow from Solutia/Monsanto where he worked in engineering technology on process control improvement. Greg was also an affiliate professor for Washington University in Saint Louis. Greg is an ISA Fellow and received the ISA Kermit Fischer Environmental Award for pH control in 1991, the Control magazine Engineer of the Year award for the process industry in 1994, was inducted into the Control magazine Process Automation Hall of Fame in 2001, was honored by InTech magazine in 2003 as one of the most influential innovators in automation, and received the ISA Life Achievement Award in 2010. Greg is the author of numerous books on process control, including Advances in Reactor Measurement and Control and Essentials of Modern Measurements and Final Elements in the Process Industry. Greg has been the monthly "Control Talk" columnist for Control magazine since 2002. Presently, Greg is a part time modeling and control consultant in Technology for Process Simulation for Emerson Automation Solutions specializing in the use of the virtual plant for exploring new opportunities. He spends most of his time writing, teaching and leading the ISA Mentor Program he founded in 2011.