This post was written by Rick Anderson of Rockwell Automation.

Industrial engineers are well aware of the electrical consumption burden their motors—especially those running pumps, compressors, and fans—put on their operating budgets. In response, they have turned to efficient motor control technologies that use just enough energy to start motors, provide diagnostics data, and reduce downtime. As motor starter adoption has widened over the years, motor starter technology has also become more sophisticated.

Motor starter methods

Common motor starter technologies include direct-on-line (DOL) starters (or across-the-line starters), soft starters, and variable frequency drives (VFDs). Understanding the application and what is critical for motor control in that application will help determine which starting method to use.

As a basic starting method, a DOL starter applies full voltage, current, and torque immediately to the motor after the start command. A soft starter, or smart motor controller, actively manages voltage to control the starting/stopping current and torque profiles to enhance the electrical and mechanical characteristics of the motor, motor circuit, and machine operation. A VFD converts the AC line voltage to DC voltage, and then inverts it back to a simulated AC voltage for the motor.

DOL methods have the most basic motor-starting capabilities, while VFDs have motor control throughout the start, stop, and run time. For applications requiring motor control only when starting and stopping, soft starters are more economical than VFDs and have more advanced control than DOL options. In addition, the soft starter and the VFD can start a motor with reduced voltage and current. They promote less mechanical wear, reduce maintenance, and often lead to other operating efficiencies in the system. Although the list of potential application considerations may feel exhaustive, the following questions can help focus decision making:

- Does the application need speed control once the motor is at speed?

- Does the application need precise starting and stopping times?

- Does the application need full torque at zero speed?

- Does the application need constant torque?

- What are the cost, size, and thermal considerations?

- Are there installation and harmonics concerns?

1. Speed control

The first consideration in choosing a motor control technology is the speed control requirements. Some soft starters have limited slow-speed control between starting and stopping. Slow speeds can vary from 1 to 15 percent of the full speed and can be used in a maintenance or alignment operation. Due to silicon-controlled rectifier (SCR) temperature rise and reduced motor cooling, this mode is meant for relatively short-term operation. Once the soft starters transition to full voltage, even though a fixed frequency is applied, the output speed is actually determined by the motor load. The operating speed of the motor cannot be varied, because the soft starter only adjusts the voltage to the motor and not the frequency.

VFDs use a DC bus and insulated-gate bipolar transistor (IGBT) switching to control both voltage and frequency. This allows full and continuous adjustable speed control. If a process requires tight speed regulation, the frequency applied to the motor by the VFD can be changed in relation to the load. In addition, the VFD output to the motor can be any frequency up to the limits of the IGBT inverter or the mechanical limits of the motor.

2. Starting and stopping times

A second consideration is starting and stopping times, and how precise they need to be. Typically, starting and stopping times with soft starters are load dependent. Internal algorithms adjust the voltage based on programmed start and stop times to increase the current and torque to start the motor or decrease them to stop it. If the load is light, the motor might start in less time than the programmed value. If the load is heavy, it may take longer to start. Some newer soft starters have implemented advanced algorithms allowing more accurate and less load-dependent starting and stopping times. On the other hand, VFDs control voltage and frequency, which allows accurate starting and stopping times with minimal load dependency.

3. Full torque at zero speed

For applications requiring full torque at zero speed, a VFD may be the best option. A VFD can produce rated motor torque from zero to rated speed, including full torque at zero speed. Soft starters operate at a fixed frequency (typically 50 to 60 hertz), and full torque is only available at full voltage. Initial torque, or torque available at zero speed, is a programmable value, which usually ranges from zero to 75 percent.

4. Constant torque

Soft starters use voltage to control current and torque. When starting, the current varies directly to the voltage applied, and the motor torque varies as the square of the applied voltage. This means that at different applied voltages, the torque is not always constant. This can be made more complicated with the loading conditions. Some soft starters implement torque control algorithms, but this does not translate directly to constant torque. Conversely, during acceleration, VFDs apply different frequencies to the motor, and voltage is changed in direct proportion to the frequency. This simple VFD control mode is often referred to as constant volts per hertz, and it produces constant torque.

5. Cost, size, and thermal considerations

At low amperage (less than 40 amps), soft starters have a slight cost advantage over VFDs. As amperage and power increase, the cost of VFDs increases more quickly than the cost of soft starters. At high amperages (greater than 100 amps), this cost can be significant.

Regarding size, soft starters have a physical size advantage over VFDs at all amperage ratings due to the physical construction of each device. As current and power increase, this difference can become exponentially large.

In addition, when paired with an electromechanical bypass (internal or external), soft starters tend to be more efficient than VFDs and typically produce less heat. This is also due to the physical construction of the power-switching devices—soft starters have less active components in the circuitry during start, run, and stop modes than VFDs.

6. Installation and harmonics

Installation considerations can be difficult to quantify, but can be classified into a few rough categories, such as cost, size, temperature, and power quality. Soft-starter installations usually have fewer concerns due to the smaller size and lower costs. If harmonic quality is a concern, soft-starter harmonics are less than those of VFDs, and long cable runs for VFDs need to be considered more carefully than those of soft starters. Special wire types are usually not needed for soft starters, and typically electromagnetic compatibility (EMC) mitigation is not needed.

Assessing soft starters

If, after considering these factors, engineers decide a soft starter is most appropriate, there are a wide array of soft starter types available. Many soft starters have multiple start functions, such as soft start, current limit, pump control, slow speed, and full-voltage starting. For stopping, many perform pump stop, motor braking, and soft stop. In addition, the need for advanced torque and speed control to start centrifugal pumps and high-inertia loads has led to new developments in soft starters.

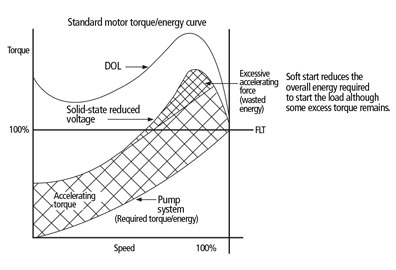

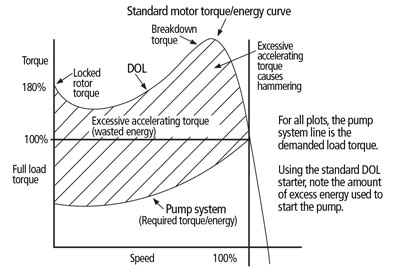

The following graphs depict sample analysis reports and displays:

These new products often have a bevy of control functions and application options, forcing engineers to reassess the performance a soft starter can now provide. Considerations include:

- Advanced starting and stopping methods: In addition to traditional starting methods like soft start, current limit, pump control, and full-voltage starting, there are new exciting control modes.

- Linear speed: Regardless of the load type, this method starts the motor in the given time without using an external tachometer. The controller uses just enough energy for both starting and stopping loads, regardless of size.

- Torque ramp: Engineers can adjust the initial and maximum torque of a defined ramp time for precise control when starting the motor. Soft start mode uses a voltage ramp. In comparison, torque ramp control is much more linear and potentially will cause less stress on the system’s mechanics.

- Slow speed: Slow speed allows short-term operation at speeds other than full speed. Operation at 1 to 15 percent of full speed in forward and reverse without a reversing contactor is useful for maintenance, adjustment, and alignment activities.

- Metering: Metering and operational information is essential for accurately monitoring performance and making timely process adjustments to improve performance and energy efficiency. If users can measure it, more often than not they can optimize it. Built-in energy and power monitoring in soft starters provide real-time energy footprint information for process optimization without additional equipment.

- Energy saver: An energy saver feature uses the soft starter’s internal feedback circuitry to monitor the load and recognize when the motor is using less energy—especially common under light loads—and adjust by decreasing the motor terminal voltage.

- Phase rebalance: Uneven line voltages can be equalized using this unique balancing algorithm. The resultant voltage waveforms potentially mitigate the uneven motor winding, heating, and bearing wear that can occur with unbalanced waveforms.

- Solid-state power structures: Benefits of solid-state power structures include improved performance in high-vibration applications, greater harsh environment immunity, higher operations per hour, scalable thermal ratings, and higher short-circuit current rating.

- Motor and controller diagnostics: User-defined system preventive maintenance, user-defined faults and alarms, tending and fault-triggered data capture, and a real-time clock provide application flexibility, diagnostic capabilities, and improved uptime.

- Network and integration capabilities: Optional communication modules allow soft starters to be integrated into a larger controls environment. This allows improved data flow and plantwide visibility. Networks, such as EtherNet/IP, allow for fast commissioning and easy integration.

- Onboard logic capabilities: Embedded user-defined control technology uses digital and analog inputs and soft-starter internal parameters to control outputs, manage information locally, and perform start/stop functions autonomously. This embedded logic often uses function block programming and can stand alone or be complementary to supervisory control.

- Scalability: Hardware expansion ports accept optional I/O and protection modules. This allows process scalability and optimizations, as well as simple-to-complex application flexibility.

When to use a soft starter or a VFD

Soft starter

- In lower-to-medium starting torque applications

- In light-to-medium loaded applications

- If little or no speed control is required during run mode

- If reduced mechanical wear and damage to system is required

- If limiting current is the primary reason for not starting at full voltage

- For lower monitoring

VFD

- In single-phase applications on certain drives

- For speed control and system efficiencies operating at reduced speeds during the run mode

- For higher starting torque

- For continuous feedback for critical position control

Engineers have many motor control options. Considering exactly what their application requires and choosing the best fit can reduce downtime, improve efficiencies, and reduce costs. The engineering choice now includes new soft starters with multiple starting methods and advanced features. Engineers can match the start/stop profile to the load with a simple control parameter change instead of swapping out control modules. The improved performance and energy savings will lighten the burden motors put on their operating budgets

About the Author

Rick Anderson is a product manager for Rockwell Automation. He is responsible for managing the SMC controllers portfolio and the identification and implementation of new product requirements.

A version of the article also was published at InTech magazine.