This post was authored by Jaime A. Alba, Peter Loomis, Robert Litzinger, Bruce P. Stevens, and Paul A. Miller.

One of the largest water reclamation facilities in northern Virginia needed to expand the facility from 18 to 24 million gallons per day (mgd) to support future growth in Prince William County, Va. At the same time, new regulations necessitated an upgrade to improve the nutrient removal capabilities of the plant.

The new waste load allocations for total nitrogen (TN) were based on permitted discharge flows with a 3 mg/L TN concentration. The Prince William County Service Authority (PWCSA) recognized the need to simultaneously increase flow and nutrient removal capabilities. At the same time, they needed to replace their plantwide data acquisition and control system (DACS) with a new modern supervisory control and data acquisition (SCADA) system.

This design-build project enhanced nutrient removal and increased capacity, doubling the existing aeration basin volume and reconfiguring to allow operation in either four-stage Bardenpho or modified Ludzack–Ettinger (MLE) modes. It implemented 14 new deep bed denitrification filters for a total of 24, and methanol feed to the filters was automated to be nitrate load paced and controlled by a proprietary software calculation algorithm. Furthermore, PWCSA installed an additional online analyzer for controlling the methanol feed to the filters for redundancy.

The proprietary software calculation algorithm for control is feedforward/feedback based upon flow and influent and effluent nitrate concentrations. This enhanced the operation and reliability of the process and also reduced the risk of methanol overdose by more closely matching the methanol feed to the actual demand. Consistent methanol dose control is challenging when trying to meet low effluent TN and simultaneously maintain a low effluent carbonaceous biochemical oxygen demand (CBOD).

This plant is currently in full operation and in compliance with the effluent requirements.

Process enhancements

Before the expansion, the plant operated with 10 denitrification filters that had insufficient surface area to process the full plant capacity of 18 mgd in denitrification mode. When the filters were operated in the denitrifying mode, flows beyond 12 mgd bypassed the filters to prevent hydraulic overloading. Even though the filters were capable of hydraulically passing the full plant flow, denitrification could not be achieved at higher flows. Based on the processing limitations and operational cost savings, the filters were often operated seasonally, with methanol added only during the winter for the additional denitrification needed to meet effluent TN requirements. During summer, the plant had sufficient denitrification capability in the secondary treatment (aeration basins) to meet effluent TN requirements, and the filters operated in a polishing mode without methanol addition to remove suspended solids.

During the design phase, the MLE and four-stage Bardenpho processes were selected for implementation based on a wide range of criteria, including capital cost, overall cost, net present value, land requirements, effluent quality, operability, maintainability, and schedule.

The plant was also required to reduce effluent total phosphorus to 0.18 mg/L. Phosphoric acid addition capability is provided in the filter's area if the filters become phosphorus limited. It was anticipated that any phosphorus allowed to bleed through to the filters or added to the secondary effluent will be removed by the denitrification filters and permit limits will not be exceeded. However, provisions were provided for future implementation of phosphoric acid feed.

The number of denitrification filters was increased from 10 to 24 to meet the new projected demands and to be able to handle when filters are offline for backwashing, bumping, or maintenance/repair.

Plantwide control system replacement

As part of this design-build project, the existing plantwide DACS was replaced. It was obsolete, with key components of the system no longer available from the manufacturer.

The facility transitioned the existing DACS to a modern SCADA system as part of the overall implementation, including designing a system with both new process area control panels and upgraded existing control panels. The final system has about 5,000 I/O points, 25 programmable logic controllers (PLCs) with a self-healing fiber-optic ring, an object-oriented human-machine interface (HMI) system, and a historian interfaced with reporting software that integrates the SCADA and laboratory databases.

The engineer of record managed construction and did quality assurance/quality control (QA/QC) for the new SCADA system and the field instrumentation portion of the project. Some of the activities included QA/QC for the new instruments, startup coordination between PWCSA and the subcontractor, onsite response to design/implementation questions and clarifications, development of maintenance of plant operations (MOPO) plans for transitioning existing and in-service systems to the new SCADA system (with the objective of minimizing the effect on plant operations), and developing and continually updating the SCADA project schedule.

Furthermore, toward the end of the project, the engineer of record also guided, witnessed, and approved the testing procedures and results for the SCADA system as a whole. This activity included network testing, uninterruptible power supply (UPS) testing, software testing, and PLC programming testing. The subcontractor performed loop testing (operational readiness test) and the functional demonstration test with coordination from PWCSA, witnessed and approved by the engineer of record.

Automation of the methanol feed system

As part of the new denitrification filters implementation, methanol feed to the filters was automated to be controlled by TETRAPace calculation algorithms. The primary method of operation was feedforward/feedback based upon flow and influent and effluent nitrate concentrations.

The calculation algorithm needs the influent and effluent nitrate concentrations. The existing ChemScan unit was used for this measurement. The ChemScan system (analyzer) is a multiparameter, multisample line analyzer that PWCSA had already been using for some time. The plant staff is used to working with it, keeping the system accurate and responsive. However, during the plant expansion, the facility decided to have a second ChemScan unit installed for redundancy and to eliminate the risk of methanol overdose if one of the units is unavailable. If only one unit was installed and was unavailable, typical programming utilizes the last known readings; however, this could result in significant over- or underdosing of methanol if the characteristics of the wastewater change, potentially resulting in permit violations for CBOD or TN. Also, overdosing methanol to the denitrification filters could occur due to the variations in the secondary effluent nitrate levels while the analyzer unit is out of service. This increase of the effluent CBOD level may cause a permit violation.

Instrumentation

In designing critical process systems, redundant systems were used. When permit limits of stringent levels are implemented, operations must use the instruments to optimize the facility and then rely on the electronic components to work reliably over time to enable compliance.

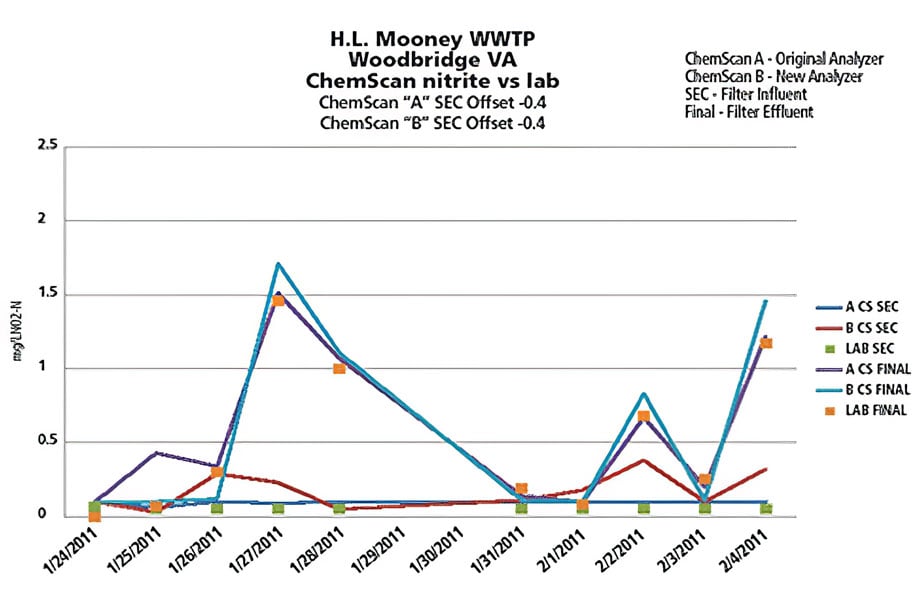

The analyzer is essentially a lab spectrometer that is automated to read more than 254 wavelengths through a process sample from before and after the denitrification filters common inlet and effluent troughs. The sample pumps constantly deliver a small stream to the analyzer, and the system alternates between each sample line in a continuous sequence to monitor ammonia, nitrate, nitrite, and ortho-phosphorous. The system also self-calibrates with a zero standard of deionized water. It self-cleans with an acidic solution to keep the total suspended solids and hardness from fouling the flow through the cell and other components in the plumbing manifold. Detection limits and process trends need to be understood, and plant staff must vet data excursions regularly to ensure the expectations of the operators are met with confidence. The data presented in figure 1 shows a nitrite excursion during startup that indicates an upset in the process, which allows the operators to react to the situation, adjust upstream processes, and adjust chemical feed systems if necessary. Figure 1 also displays how the data from the ChemScan analyzers and the grab samples are very close to each other, confirming the calibration of the instrumentation.

Figure 1. ChemScan nitrite analysis during startup

Figure 1. ChemScan nitrite analysis during startup

Online analyzers mainly provide intermittent data, which gives the effect of sharp high and low points in graphical terms, so operators must understand that these peaks and valleys are much smoother and time depressed than seen here. Process control decisions cannot be made on single points of data that stand uncorroborated. Patterns with repeatable trends and occasional outliers in the data are used to make rational decisions with and after vetting equipment.

Online monitoring devices can help run a facility better, but they are not foolproof and need regular care and inspection. Maintenance instructions and protection of transient electrical power surges must be done to protect the investment in this data gathering infrastructure.

At the same time, and as part of the design-build expansion project, a backup methanol feed pump was installed so that the loss of methanol feed to the denitrification filters (when running in denitrification mode) is minimized during a failure or scheduled maintenance for the main feed pump. Also, as part of the plantwide DACS replacement, the network backbone was designed with a self-healing fiber-optic ring to minimize the risk of losing the SCADA system and with UPS systems to prevent spikes and brownouts from damaging the critical equipment of the control system.

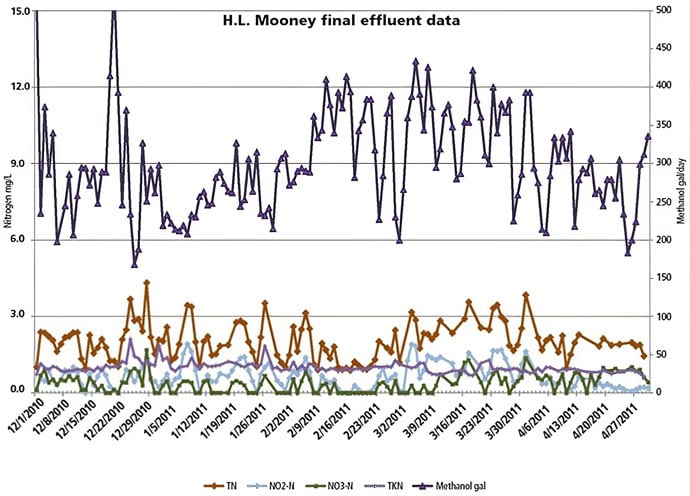

This whole implementation enhanced the plant operations and reliability of the process, and also reduced the risk of methanol overdose by more closely matching the methanol feed to the actual demand (figure 2). Consistent methanol dose control is challenging when trying to meet low effluent TN while simultaneously maintaining a low CBOD.

Figure 2. Effluent nitrate and nitrite concentrations, and methanol feed rates after the upgrade

Figure 2. Effluent nitrate and nitrite concentrations, and methanol feed rates after the upgrade

During construction

One of the biggest challenges during this plant upgrade was the coordination, planning, and execution of the MOPO plans. Because the plant had to be kept online during this upgrade, there were many factors to consider to minimize the plant downtime. One of the key factors was to test the hardware and software before it even was shipped to the plant. Once the equipment was onsite, another thorough test was executed to test the field connections and installation.

The startup process was done in phases, taking into consideration that not only the instrumentation, but also the plantwide control system was being transitioned and that there were construction aspects of the project that had to be considered as well. This led to an initial setup and calibration of the TETRAPace calculation algorithms and the analyzer units that later had to be changed to accommodate the different conditions of the phased approach.

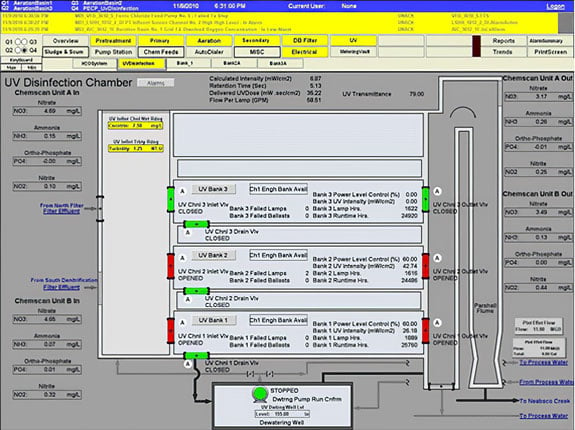

Due to the redundant analyzer units setup, the PLC and HMI systems were programmed and configured to accommodate this redundant system. A screen shot of the ultraviolet system area is displayed in figure 3, where the readings of both analyzer units are displayed.

Figure 3. Filters influent and effluent ChemScan units readings

Figure 3. Filters influent and effluent ChemScan units readings

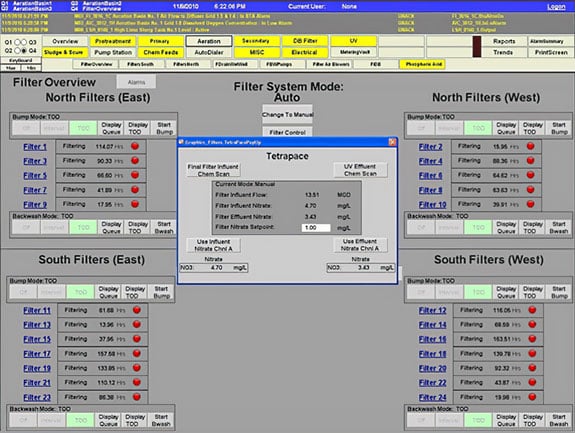

At every operator workstation, which are distributed throughout the plant, the operators have the option to select which analyzer unit readings to use in the calculation algorithms. Figure 4 shows a screen shot of the denitrification filters area where the operators can select which analyzer unit readings to use for the calculation algorithms. This also added flexibility for maintenance of the analyzer units.

Figure 4. Filters TETRAPace calculation and ChemScan readings selection

Figure 4. Filters TETRAPace calculation and ChemScan readings selection

Additionally, PLC programming and HMI development for the denitrification filters were implemented as an integral part of the SCADA system instead of having a vendor system communicating to it. This gave the plant staff a more standardized approach to facilitate future changes and maintenance to either of the systems.

Operational and economic benefits

As already mentioned, one of the main operational benefits is that the risk of methanol overdose was greatly reduced by more closely matching the methanol feed to the actual nitrate and nitrite changes when feeding methanol to the filters. This enhanced control simultaneously maintains a low CBOD. The denitrification filters can now denitrify meeting permit limits up to average day maximum month loading.

New denitrification filters

New denitrification filters

At the same time, and as a consequence of the improvements made to the aeration basins, plant operations fed methanol to the denitrification filters until about August 2011, very close to the substantial completion date of the project. Currently, the plant is able to completely denitrify to below 3.0 mg/L of TN consistently in the aeration basins. The fact that the plant is currently flowing at about 50 percent capacity might be an important factor for this, but if the flows increase and there is the need for it, methanol can be fed to the filters again.

With the lower flows through the aeration basins, the plant can operate year round in the four-stage Bardenpho mode with maximum anoxic zones. The mode of operation still allows complete nitrification in the aeration basins and maximized volume available for denitrification. At the same time, with the higher retention times, the plant can support a biological phosphorous accumulating organism in the aeration basins, allowing operations to stop all ferric chloride feed to the secondary system while maintaining ferric chloride feed to the primary clarifiers to meet the total phosphorus limit.

On the economic side, the daily average methanol consumption to the filters went down from about 413 gal/day to close to 300 gal/day. Methanol is fed to the filters for an average of 8 months a year, which translates to about 27,000 gallons less methanol used per year. Additionally, since currently sufficient denitrification is taking place in the aeration basins when operating in the four-stage Banderpho mode and no methanol is being fed to the filters, this means that the methanol savings would be about 41,000 gallons per year, above the 300 gal/day of filter methanol that was moved to the aeration basins to improve the nitrate reduction. With a gallon of methanol being about $1.755, this translates into a yearly savings of about $71,955. In other words, what was done before the upgrade to save money on methanol consumption by running the filters in polishing mode has now become normal operations for the plant.

Success

The H. L. Mooney advanced water reclamation facility upgrades became necessary because the average daily flows were reaching 85 to 90 percent of the plant capacity and further growth was expected. Additionally, PWCSA wanted to maintain a waste load allocation based upon 3 mg/L of effluent TN at the future flow capacity of 24 mgd. In addition to the process upgrades to the aeration basins and denitrifying filters, the upgrades included improved controls for the denitrifying filters, allowing a reliable methanol feed control to minimize methanol costs while also ensuring adequate feed.

Redundant ChemScan

Redundant ChemScan

The modifications to the overall plant have allowed a significant reduction in overall chemical usage for both methanol and ferric chloride. Ferric chloride use was reduced due to the increased volume in the aeration basins, resulting in biological phosphorus removal. Furthermore, the improved controls incorporated into the denitrification filters resulted in a reduction in methanol usage by approximately 25 percent while still meeting effluent nutrient loading criteria. Finally, the methanol reduction at the filters can be traced directly to the use of a load-based methanol addition algorithm for the denitrification filters.

About the Author

Jaime A. Alba, P.E. is a senior process control engineer working in the water and wastewater industry. His experience includes SCADA, HMI, and PLC design, implementation, startup and commissioning, as well as execution of QA/QC procedures and construction management.

About the Author

Peter Loomis, P.E. is a senior project manager with work in the water and wastewater industry. His experience includes treatment plant planning, design, construction, and startup/commissioning.

About the Author

Robert Litzinger is a water reclamation facility operations manager with a Virginia class I wastewater operator license and experience in the wastewater field. His experience includes the initial commissioning of the plant as well as plant upgrades.

About the Author

Bruce P. Stevens is a regional manager with ASA Analytics/ChemScan of Waukesha, Wis. He is based in Atlanta, Ga. and covers the southern U.S. working with municipalities and industrial clients.

About the Author

Paul A. Miller is a process engineer with experience in the municipal and industrial water and wastewater industry. His experience includes operating pilot studies, biological gravity, and pressure filter designs, metals removal technology design, and startup and commissioning of more than 90 treatment systems.

A version of this article also was published at InTech magazine.