The following insights are part of an occasional series authored by Greg McMillan, industry consultant, author of numerous process control books and a retired Senior Fellow from Monsanto.

For both batch and continuous reactors, completion control seeks to provide a complete conversion of all the reactants and consequently no excess accumulation of a reactant in a particular phase. If the reactants are in different phases and the product is a single phase, inventory control can be used for reaction completion control. The product must  be a gas, liquid, or solids with no recycle or co-products in the other phases.

be a gas, liquid, or solids with no recycle or co-products in the other phases.

Inventory control is possible if there is a discharge flow in addition to a feed flow to the phase. Gas volumes have a continuous discharge flow in batch as well as in continuous reactors by means of an off-gas flow going to a vent or recovery system. Liquid and solid volumes only have a discharge flow in continuous operations unless there is a phase separator physically built-in to continuously separate solids from liquids during batch operation (e.g., a hydroclone in a recirculation line).

Insight: Completion control seeks to provide for batch and continuous reactors a complete conversion of all reactants.

Multiphase reactors offer an inherent ability to optimize excess reactant concentration by the proper use of a simple pressure or temperature control loop. The remaining optimization opportunity is in terms of setting the best purge flow. See Greg McMillan’s new ISA book Advances in Reactor Measurement and Control for an extensive view of practical opportunities for designing control strategies to achieve product quality and maximize yield and capacity in different types of reactors.

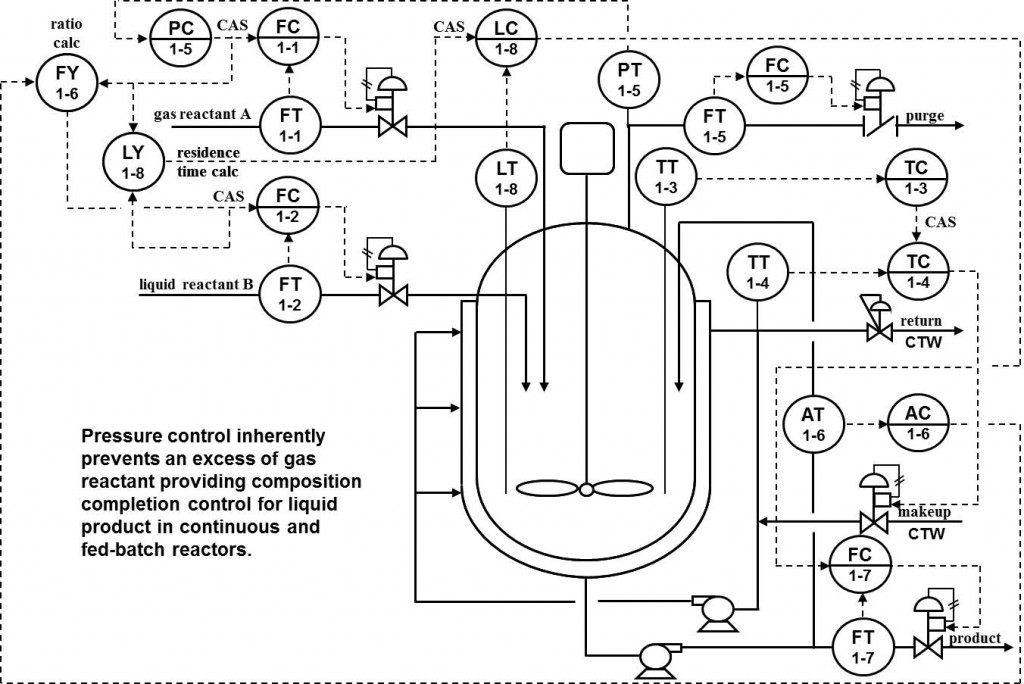

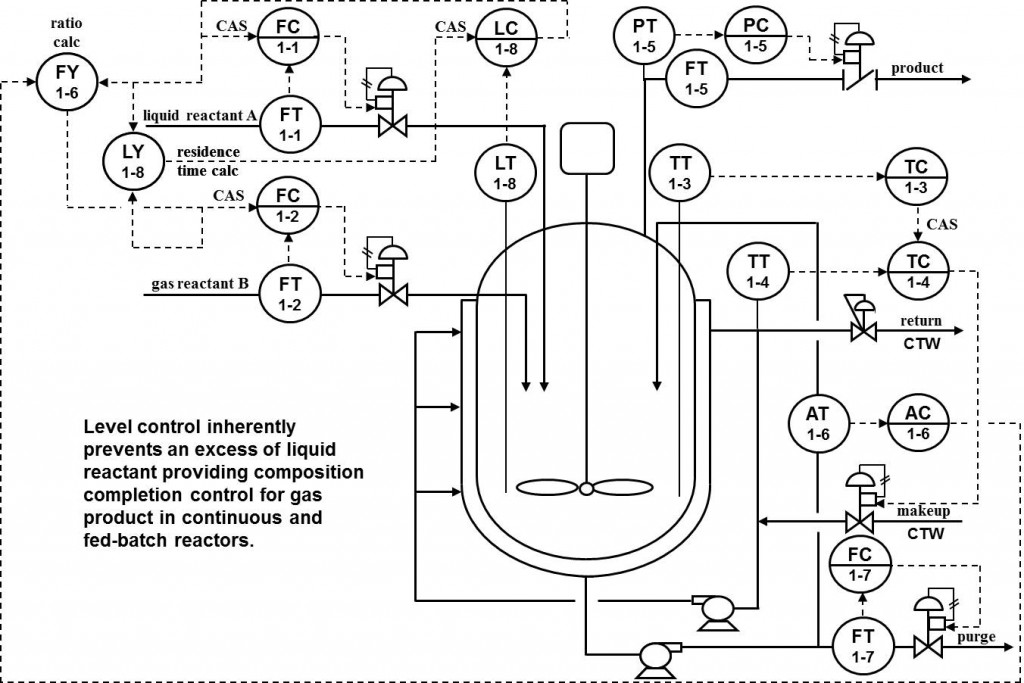

Using these concepts one can determine whether inventory control provides completion control. For a liquid product, excess gas reactant is inherently prevented by pressure control for both batch and continuous processes. For a gas product, excess liquid reactant is inherently prevented by level control for continuous processes and possibly solids control for all processes.

Insight: For multiple phase reactants and a single phase product, inventory control can provide reaction completion control. Batch processes do not have liquid inventory control (level control) to prevent the accumulation of reactants in the liquid phase.

For a liquid product, a pressure controller provides continuous completion control by increasing gas feed for a decrease in pressure from a deficiency of gas reactant and by decreasing gas feed for an increase in pressure from an excess of gas reactant (Figure 1). The gas phase reaction is normally fast enough for the gas reactant to be totally consumed in the reaction so that only the inerts are left in the overhead vapor space. An off-gas purge flow prevents the accumulation of inerts. A level controller maintains the liquid material balance by manipulating the liquid product discharge flow.

The residence time control by the level loop shown for a single phase liquid reaction (Figure 4) could help maintain the residence time in the gas phase as well the liquid phase by keeping the bubble rise time constant. The bubble rise time is the bubble path length set by level divided by the bubble velocity set by sparge rate. For pure batch and fed-batch reactors there is no level control and hence no residence time control but otherwise the control scheme is applicable.

Insight: An off-gas purge of inerts enables gas pressure control to provide reaction completion control in the gas phase for a liquid product.

For a gas product, a level controller provides continuous completion control by increasing liquid feed for a decrease in level for a deficiency of liquid reactant and decreasing liquid feed for an increase in level from an excess of liquid reactant (Figure 2). A purge flow from the bottom prevents the accumulation of inerts in the liquid phase. A gas pressure controller maintains the gas material balance by manipulating the gas product discharge flow. For residence time control, the liquid controller setpoint computed as the liquid reactant flow multiplied by the desired residence time would need a lag inserted because the level controller manipulating the liquid reactant flow forms a positive feedback loop. For fed-batch reactors this strategy is not applicable because there is no level control or purge.

Insight: A bottom liquid purge of inerts enables liquid level control to provide reaction completion control in the liquid phase for a gas product.

Production rate can be maximized in both cases by the use of a valve position controller (VPC) monitoring coolant valve position. The VPC setpoint is the maximum desirable valve position, and the VPC process variable is the temperature controller output. The output of the VPC trims the setpoint of the liquid and gas reactant flow controller for liquid and gas products, respectively. An enhanced PID with dynamic reset limiting for the VPC eliminates limit cycles, reduces interaction between the VPC and temperature controller, and enables smoother optimization with faster correction for disturbances.

The purge flow for both types of reactor presents an opportunity for optimization. An excess accumulation of inerts reduces the residence time and reaction rate. Inhibiters can reduce yield and initiators of undesirable compounds can cause poor product quality besides reducing yield. First principle models can provide an inferential measurement of inert, inhibiter, or side reaction initiator accumulation. The predicted accumulation is corrected by at-line or off-line analyzers of the concentrations in raw materials (reactants) and phases within the reactor. It is important that research studies be conducted on the type of inerts, inhibiters, and initiators of undesirable reactions that can be found in the reactant feeds and their effect on reaction rate and yield.

For a single liquid product, use tight gas pressure control to prevent excess reactants in the gas phase and optimize a gas purge. For a single gas product, use tight liquid level control to prevent excess reactants in the liquid phase and optimize a liquid purge. In both cases use research studies and measurements of components in raw materials and reactant phases that adversely affect reactor yield and capacity to optimize the purge rates.