This is an excerpt from the November/December 2013 issue of InTech magazine by Thomas J. Burke, OPC Foundation president and executive director. To read the full article, please see the link at the bottom of this post.

Is the concept of open standards all myth and magic? Is there a real business and technical value proposition for open standards like OPC that justifies the end users demanding the suppliers to deliver? How does OPC provide timeless durability and deliver specifications and technology that the suppliers build into their product portfolios? This article explores the OPC vision, and the who, what, when, where, and why of OPC interoperability in 2014.

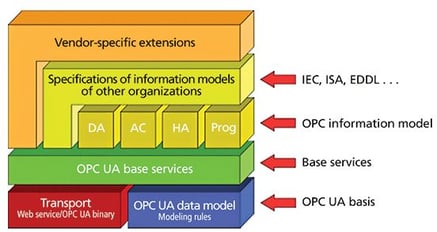

OPC became the de facto standard for data acquisition for discrete and process control applications, and over time has evolved and revolutionized industrial automation multiplatform interoperability. The OPC Foundation strategy is providing the infrastructure to enable the community of suppliers, consortia, and end users to collaborate to bring interoperable products to market. In addition, the OPC Foundation had established a certification program that validates the interoperability of products to meet and exceed the quality standards of the end user community.

What are the benefits?

Typically suppliers have always preferred the brand-loyalty architecture; we want our end users to only use products from "our" company and our preferred suppliers. The suppliers assert and assume they know what their end users want and need! Suppliers always tell the story that standards are the least common denominator approach, and they can give users better compatibility and performance along with guaranteed interoperability with their proprietary architectures.

The world of consumer electronics and the expectations set with out-of-the-box multivendor plug-and-play interoperability is changing the world. End users have high expectations that technology innovations in consumer electronics must be propagated to industrial automation, and that tablets and smartphones must be integrated with their industrial automation devices and applications.

OPC Foundation

Has the OPC Foundation successfully delivered the right technology and value proposition to change the landscape of industrial automation and related domains?

OPC2OPC was started in 1995 by a group of companies that had the vision for a simple interface that allowed first-tier visualization applications on Microsoft platforms to read and write data from process control and factory automation devices. The value proposition at that time was simple; vendors were looking to make their lives simpler and more cost-effective. They did not want to be burdened with continual development of complex device-driver software to talk to the myriad devices. Before OPC, companies had developed their own "proprietary open" technology and distributed tool kits to multitudes of vendors to develop software as an interface for their software to discrete and process devices.

When OPC first started, it was all about a small set of vendors. It was a community thinking and collaborating to solve a critical problem of moving data from the factory and process control devices to the first-tier visualization applications. The key concept here is a community collaborating together.

OPC continued to develop new standards beyond the first data-access specification that was developed in the mid-1990s. OPC solves problems beyond data access, including specifications for alarming and historical data access. The Microsoft platform-based specifications of data access, alarms of events, and historical data access are now labeled the classic OPC specifications.

To read the full article on OPC standards, click here.

About the Author

About the Author

Thomas J. Burke is the OPC Foundation president and executive director. He was one of the original architects of OPC, and his vision of interoperability is to develop and maintain the best technology, specifications, certification, and process to enable multivendor, multiplatform, secure, and reliable interoperability for and between industrial automation and related domains. Contact Thomas at: thomas.burke@opcfoundation.org.