This guest post is authored by Ned Espy, technical director at Beamex. This post was written in conjunction with an ISA co-hosted webinar on differential pressure flowmeter calibration. This is Part 1 of the two-part ISA webinar series. To watch the webinar recording for Part 2, click this link.

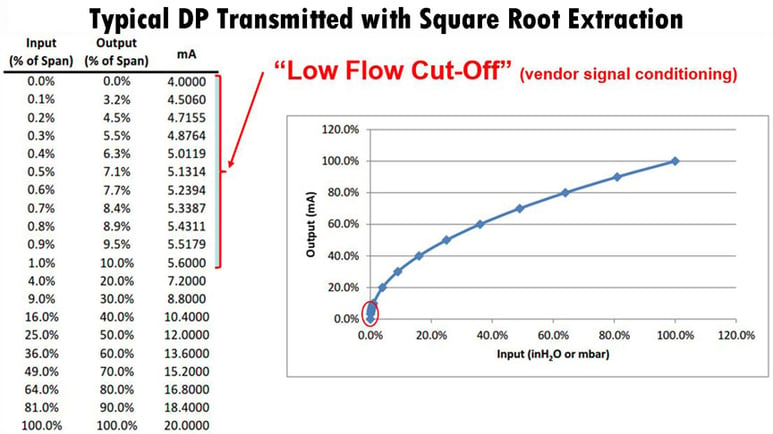

For flowmeter calibration, the phenomenon of “low flow cut-off” is only associated with differential pressure transmitters with square root extraction—if the square root (flow) calculation is done in the control system (DCS/PLC), then this test approach does not apply. The graphic below illustrates the issue.

Some may ask why we are testing the initial point at 10 percent and may be concerned that we are not measuring the first 10 percent of flow. Note in the graphic above how rapidly the output flow signal (mA) changes with a very small change in the differential pressure input. For testing such a transmitter, the first 10 percent of flow cannot be used to meter the process because it is unstable, unpredictable and vendors filter that portion of the signal.

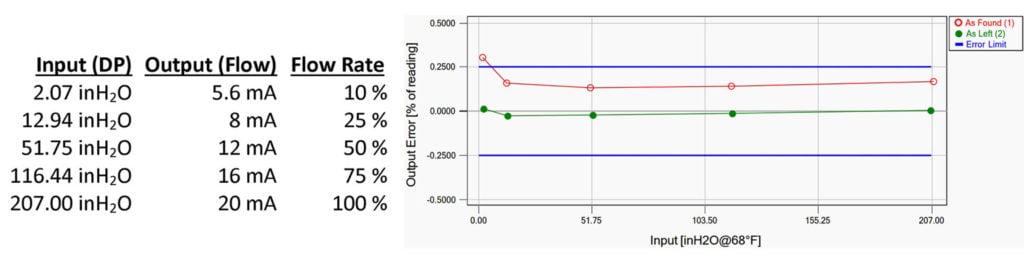

In demonstrating how to test and trim a DP transmitter, our first test point was actually at 1 percent of the input (DP) which represents 10 percent of the output (flow). When the signal is below this value, it is usually converted to zero by the control system because it jumps around too much. The graphic below displays recommended example test points and a graph of actual test data.

If your application requires accurate metering below 5.6 mA (less than 1 percent of the differential pressure, which is less than 10 percent of the flow rate), then you will need a secondary meter with a lower range (for example, 0 to 30 in H2O would complement a 0 to 207 in H2O range).

Takeaway: There is no reason to test a differential pressure transmitter with square root extraction below 1 percent of DP/10 percent of flow (mA). Check with your control engineer to see if they utilize a low flow cut-off strategy.

Takeaway: There is no reason to test a differential pressure transmitter with square root extraction below 1 percent of DP/10 percent of flow (mA). Check with your control engineer to see if they utilize a low flow cut-off strategy.

To watch the webinar recording for Part 2, click this link.

Blog Posts

How Often Do Measurements Need to Be Calibrated?

Just in Time, or Just Too Late? A Kaizen Approach to Calibration

How to Improve Industrial Productivity with Loop Calibration

Temperature Calibration: Using a Dry Block to Calculate Total Uncertainty

How Can Advanced Calibration Strategies Improve Control Performance?

How to Calibrate a Pressure Transmitter

Webinar Recordings

Uncertainty in Calibration

Calibration Uncertainty and Why Technicians Need to Understand It

How to Avoid the Most Common Mistakes in Field Calibration

Learn Advanced Techniques in Field Calibration

How to Build an Industrial Calibration System Business Case

How to Use Calibration Tools for Accurate Process Temperature Measurement

How Does Low Flow Affect Differential Pressure Flowmeter Calibration?

Three Common Pitfalls of Pressure Calibration

Webinar Recording: How to Calibrate Differential Pressure Flowmeters

Free Downloads

ISA Industrial Calibration Worksheets

Measurement Uncertainty Analysis Excel template plus book excerpt

Calibration Handbook of Measuring Instruments book excerpt

In-Depth Guide to Calibration for the Process Industries eBook

Calibration Uncertainty for Non-Mathematicians white paper

About the Presenter

Ned Espy has been promoting calibration management with Beamex for more than 20 years. He has directed field experience in instrumentation measurement application for over 27 years. Today, Ned provides technical & application support to Beamex clients and partners throughout North America.