AutoQuiz is edited by Joel Don, ISA's community manager.

Today's automation industry quiz question comes from the ISA Certified Control Systems Technician (CCST) program. Certified Control System Technicians calibrate, document, troubleshoot, and repair/replace instrumentation for systems that measure and control level, temperature, pressure, flow, and other process variables. Click this link for information about the CCST program. This question is from the Level III study guide, Domain 2, Loop checking. Level III represents a professional who has a 13-year total of education, training, and/or experience.

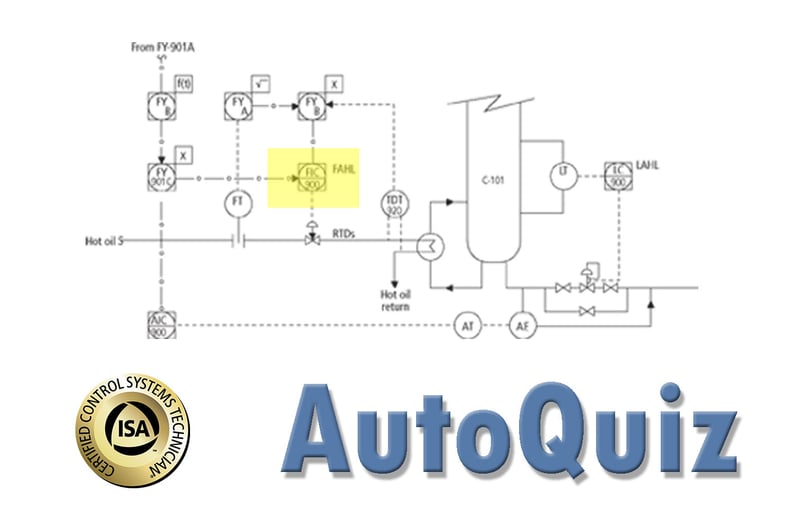

In the post graphic (highlighted), a loss of power to FIC 900 will result in the:

a) level in C-101 to increase

b) level in C-101 to decrease

c) output of TDT 920 to increase

d) output of TDT 920 to decrease

e) none of the above

A loss of power to FIC 900, which is a flow controlling mechanism and opens and closes the valve, causes the valve to automatically close-Fail-Closed (FC). Symbols for failure modes are on the line between the valve symbol and the actuator symbol. The arrow pointing down, as it does here, indicates FC.

If the arrow had pointed up, that would indicate Fail-Open.

Therefore, with the valve closed, hot oil quits flowing through the line. The purpose of this flow is to transfer heat from the oil to the contents of the process vessel C-101.

TDT 920 measures the difference in the temperature of the hot oil flow before and after it contacts and transfers heat to the contents of C-101. Since there is no flow, the difference in temperatures of the two pipe sections move toward the same (ambient) temperature. Thus the difference in temperatures, and therefore TDT 920 output, decreases.

The correct answer is D.