This blog post was written by Mart Berutti, president and COO of MYNAH Technologies LLC.

The oil and gas production explosion is driving the renaissance of the chemical and process industries. With low-cost natural gas comes low-cost feedstock for many chemical compounds, in the form of ethane, propane, and butane, economically boosting the chemical industry. The American Chemistry Council released a report predicting capital investment of $72 billion in more than 100 new chemical plant projects through 2020 in North America alone. The report claims this investment will result in 500,000 additional jobs, many in plant operations.

In spite of all this good news, operations managers at process plants have greater challenges than ever before. Worker safety, environmental stewardship, process uptime, and conservation of plant resources have been common goals for plant operations for the past several decades. In addition to these goals, new challenges are stretching the limits of plant operations.

The challenges are real and must be addressed. The good news is that lifecycle dynamic simulation, the virtual plant, is an available, proven technology to help plant operations address these challenges.

Demographic time bomb

Who is going to run the process plant of the future? The term “demographic time bomb” describes the upcoming crisis in the process industry in finding experienced operations personnel. The U.S. Department of Labor reports the average age of energy industry workers is older than 50, and half the current workforce (more than 500,000 workers) is expected to retire over the next five to 10 years. As these experienced operators leave industry, they take with them an irreplaceable amount of knowledge and experience. Although older operators came from a predigital age and relied upon mechanical skills and experience, younger operators, in general, have fewer mechanical skills, but are adept at using technology at their jobs. The operators of the past, who could diagnose compressor health by sound, are being replaced by a new generation more comfortable behind a computer display.

Seven years to operator competency

How long does it take to develop a competent operator? A study from the Oil and Gas Journal states that it takes, on average, seven years for new workers to achieve a competence level to make or recommend appropriate risk decisions. These seven years conflict with the average worker’s expectation of staying only five years in one position. This means that in many process plants, members of the operations staff are looking for their next positions before they become competent in their current roles.

Petrochemical and energy plants have already been compromised by their lack of qualified operators. A fertilizer plant in the Midwest claimed if it lost one more experienced operator, it might not be able to run the plant. It was one good operator away from plant closure.

Automation saves money, adds complexity

Can we apply automation to address this challenge? Well, the lack of operations experience makes the role of process automation critical to success. Modern automation technology has an excellent return on investment; it can be used to operate process plants with fewer qualified operators. Highly automated plants also have fewer operations-related errors. Modern control systems are very advanced and can handle many tasks quicker, safer, and at a lower cost than a human operator can. And advances in automation system and process technology allow process plants to operate longer without downtime.

However, in a highly automated plant, the role of the operator is different and more difficult. The operator now has to monitor a sophisticated system and make decisions about the health of the process and the performance of the system based on information from the operator console. With the industry trend to remove the operator from the dangerous process area, the control room operator station becomes the only window to the process in many plants.

Also, because the system and process are more reliable, operators may seldom or never see upset conditions. They can quickly lose critical skills necessary to deal with those situations. This often causes compromised operating conditions. Studies show that the greatest cause of operational loss in the process industries is due to operator error.

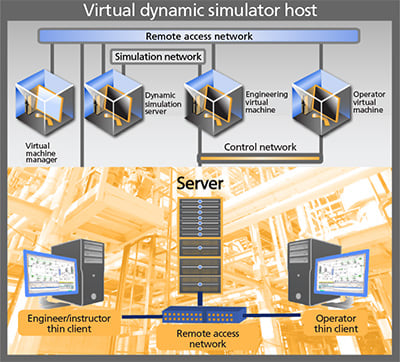

A virtual “private cloud” implementation brings the greatest benefits of security, accessibility, and ease of use. The example shown includes a dynamic simulation virtual server providing I/O and process simulation, offline control system virtual workstations, and a hypervisor management virtual appliance.

A virtual “private cloud” implementation brings the greatest benefits of security, accessibility, and ease of use. The example shown includes a dynamic simulation virtual server providing I/O and process simulation, offline control system virtual workstations, and a hypervisor management virtual appliance.

Risks in process automation

Should we automate these new processes? Of course, investment in automation and new technology is critical to meeting the goals of these process investments. However, there are risks in automation projects. Although modern process automation systems have great reliability and performance, the risks introduced by human engineering and operations still remain. These risks are:

- Hidden errors and issues in the automation system application software undetected until they cause process or operational issues.

- Inappropriate operator actions or, conversely, operators not taking action when they should.

- Operating procedures that are in error or incomplete, so they are not used or trusted.

In addition, government bodies continue to pressure process plants to document their efforts to administer a safe and effective operations environment. Initiatives like the OSHA National Awareness Program require operations management to prove adherence to standard operating procedures, control system standards, and other plant operation documentation. Insufficient evidence to due diligence can result in fines or citations.

Why not operations simulation

None of us would want to get on an airplane with a pilot who is not trained. Why would we want someone to run our plants without proper training? To  prepare a commercial airline pilot to operate a new airplane, weeks of training in a flight simulator is mandated, as well as hours of instruction and study. Shouldn’t process plant operators have the same time of preparation before managing complicated processes?

prepare a commercial airline pilot to operate a new airplane, weeks of training in a flight simulator is mandated, as well as hours of instruction and study. Shouldn’t process plant operators have the same time of preparation before managing complicated processes?

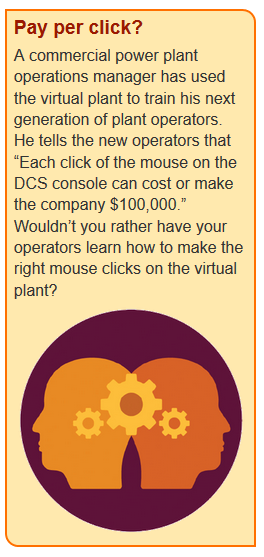

Consider that a typical pilot has more than 100 variables to manage from the cockpit. It is not unusual for a process plant operator to manage more than 1,000 variables from one control room console.

So, is there any evidence to the value of dynamic simulation? In a survey of users of dynamic simulation by World Oil Online, users reported an average increase in operator effectiveness of 31 percent. The same survey attributed an average total savings of $15.3 million from the use of the simulator. The value of using dynamic simulation has been proven time after time, but not everyone who would benefit from one is using one

Barriers to using simulation

Why don’t all process plants use a dynamic simulator? For one thing, the solutions traditionally offered in the industry are difficult to use and require extensive customization. Traditional approaches to dynamic simulation have made system maintenance a nightmare. In that same World Oil Online survey, 52 percent of the respondents said that they seldom or never updated their simulator. The investment to update traditional approaches to dynamic simulation can be significant.

Finally, these traditional solutions are seldom built to support automation system and operational improvement. But this application can be just as important as operator training. Most dynamic simulation systems are justified as an operator training system. However, if a lifecycle dynamic simulation approach is followed, issues are uncovered in the automation system or operation of the plant that could be catastrophic when operating the plant.

A recent lifecycle dynamic simulation showed a major operational issue on a chemical process in the Houston area that has been running for nearly 20 years. The plant was designed so it could conduct maintenance and improvements without shutting down, eliminating the need for a cold start. At the same time, the plant experienced a high turnover in operators and needed to validate its start-up procedures. A dynamic simulation of the plant allowed the organization to verify all standard operating procedures, including the cold startup. None of the operators could start the plant in the simulator. The plant engineering team found significant automation issues keeping them from starting up the plant. The dynamic simulator allowed them to correct the control system and verify the start-up procedures.

In most cases, the benefits from automation and operational improvements are the same or greater than the benefits from an operator training system. Training operators and making automation changes on the running plant are costly and dangerous. A better approach to applying the benefits of dynamic simulation offers hope for plant operations.

Process plants need a virtual plant

The better approach is investing in a lifecycle dynamic simulator or virtual plant. The exact same operator graphics, alarms, and controls used in the online control system are copied into a control system simulator made by the control system vendor. The operator works on an exact replica of the system in the control room, and the organization uses a real-time, dynamic model of the I/O and process to provide I/O signals to the simulated control system. The operator and control system appear to be controlling the actual process. Finally, the entire solution is implemented in a virtual, private cloud environment.

Lifecycle business results

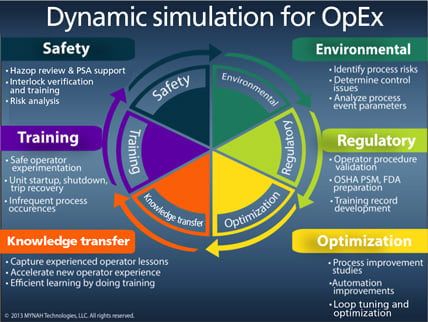

The investment in a virtual plant brings excellent returns for the lifecycle operation of the process plant. In addition, by using the virtual plant for capital projects, companies can realize additional business benefits. A lifecycle approach provides value across all aspects of running a process plant, including safety, environment, regulations, operator training, and process optimization.

- Process control improvements can be developed, tested, and demonstrated to operations management without affecting the operation or production of the actual plant. If implemented correctly, the control system configuration developed in the lifecycle dynamic simulator can be exported directly to the process automation system, minimizing operational risk. Users report system start-up savings of weeks or even months with returns of $500,000–$5,000,000.

- Training new operators on process operations, start-up and shutdown procedures, and hazardous or infrequent process occurrences can be accomplished without affecting the running process. Process plants run well and trip less, resulting in operational savings of $1,000,000 or more per year.

- Evaluating new and experienced plant operations can be done on predeveloped training scenarios. Plant operations competency requirements can be established and reinforced with repeatable, measurable, and documented training sessions. Trained operators make fewer mistakes. Avoiding process plant upsets or shutdowns can save $500,000–$1,000,000 per incident.

- Process optimization and modification studies can be done on the dynamic simulator, giving the process engineers a tool that accurately models the process dynamics not seen in steady-state design models. Process changes with control improvements can be thoroughly tested before construction begins, reducing rework and start-up times. Advanced control strategies are tested, tuned, and validated offline, reducing operational losses by $100,000–$500,000. Evaluating new operating procedures for different conditions can bring operational savings of 1–2 percent or $1,000,000–$2,000,000 per year.

- Process and regulatory documentation can be developed and tested on the dynamic simulator without affecting the operation of the process. One user claimed operations savings of $1,000,000 per year by using the virtual plant for regulatory documentation development.

- The benefits are proven. Plants that incorporate the virtual plant into their automation and operations planning save time and money. In this age of great challenges, plant operations need proven solutions to help survive.

The lifecycle approach to dynamic simulation provides the greatest benefits to process plant operators, from operator training to control system performance and operational improvement. With the pressure mounting on process plant operations, it is time to use this effective technology to address the challenges faced by the industry.

The investment in lifecycle dynamic simulation provides excellent returns for the lifecycle operation of the process plant. Best-practice use of the virtual plant improves all aspects of successful operation of the process, including safety, environment, regulations, training, and unit optimization.

The investment in lifecycle dynamic simulation provides excellent returns for the lifecycle operation of the process plant. Best-practice use of the virtual plant improves all aspects of successful operation of the process, including safety, environment, regulations, training, and unit optimization.About the Author Mart Berutti is the president and COO of MYNAH Technologies LLC. He has more than 25 years of experience in the fields of dynamic process simulation, control system validation, industrial Ethernet integration, and operator training. Berutti has been with MYNAH since its founding in 2002. He is a chemical engineering graduate from the Missouri University of Science and Technology.

Mart Berutti is the president and COO of MYNAH Technologies LLC. He has more than 25 years of experience in the fields of dynamic process simulation, control system validation, industrial Ethernet integration, and operator training. Berutti has been with MYNAH since its founding in 2002. He is a chemical engineering graduate from the Missouri University of Science and Technology.

Connect with Mart:

A version of this article also was published at InTech magazine.