Globalization has been a very successful strategy for many businesses. Distributing the supply chain across the world and capitalizing on lower-cost locations has helped improve productivity and reduce costs.

When major disasters or emergencies happen, organizations may need to put into play their emergency response or continuity of operations plans. In recent years, we’ve seen major flooding, earthquakes, and extensive wildfires disrupt business. Pandemics, though, are on an entirely different level of disruption. While organizations may be able to move parts of their supply chain out of affected areas, the affected area in a pandemic is, by definition, something that covers multiple continents.

The top 10 shipbuilders in the world are all based in Asia. Most of the world’s largest marine construction projects will be found in these yards. These projects are always on tight timescales, with major pressure on their sponsor for on-time delivery. So, what do you do during a pandemic where large parts of Asia shut down, or if your workers need to be demobilized from there to minimize the threat of infection?

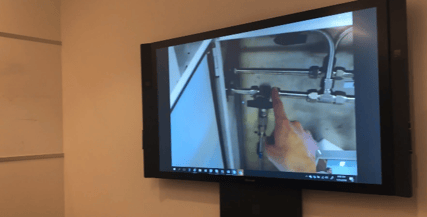

Immersive technology, such as smart glasses, may be one solution to address this challenge. It is now possible to have someone local wear the glasses and make a video/voice call with others, so that they can be part of the inspection process. The local engineer can work normally, with hands free, and the remote users can see exactly what the local engineer sees. Nothing is perfect, but when faced with an unexpected challenge like COVID-19, this solution is much better than the alternatives.

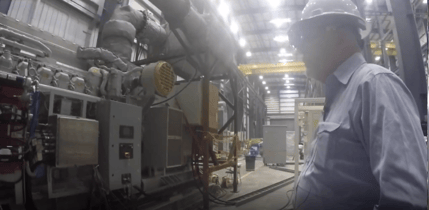

An example of using immersive technology to enable remote inspection: at left, an engineer on site is wearing a smart glass solution.

An example of using immersive technology to enable remote inspection: at left, an engineer on site is wearing a smart glass solution.

At left, inspectors can interact with this engineer through a video/voice call and see whatever he sees.

Images courtesy of Steve Mustard

ISA’s upcoming event, Digital Transformation in Deepwater Production, will look at immersive technology and many other leading-edge concepts. We will look at how they can be deployed to improve performance and safety and how to manage operations in this more uncertain time.

We are monitoring the COVID-19 situation, but please plan to come and join us in Galveston, Texas, 16-17 September 2020.

About the Co-Authors

Steve Mustard is an independent automation consultant and the 2021 ISA president-elect. Ken Nguyen is the digital program manager at BP and the chair of ISA's 2020 Digital Transformation in Deepwater Production Conference.