This article was written by Paul Brandenburg a senior consultant with Brillig Systems.

Delivering an integrated manufacturing execution system (MES) is complex; however, by focusing on the key factors outlined in this article, successful projects have been implemented. Folklore among many automation and IT professionals is that MES projects are complex, expensive, and never complete. This article illustrates how to develop a high-level understanding of the MES system implementation process with concrete examples of how automation and IT delivery teams can function together to ensure success.

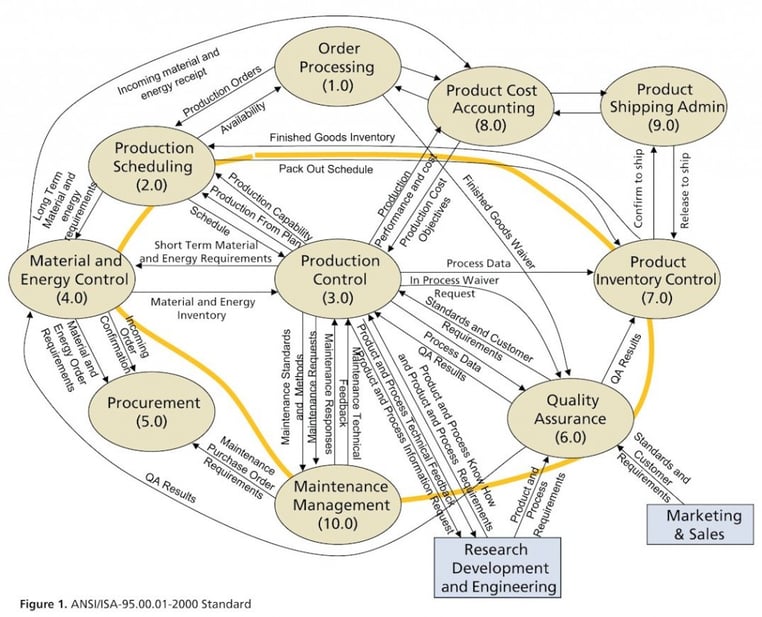

The ANSI/ISA95.00.01-2000 standard, shown in Figure 1, defines 10 functions related to the production operations; it also defines the boundaries between enterprise (business systems) and control (MES/automation systems) domains. One excellent first step to a successful project execution is reviewing the standards documentation as a way to provide a common language related to data structures and interface definitions for discussions between automation and MES execution teams.

For the purposes of this article, we will focus on the following three major MES functions:

- Production operations management

- Quality operations management

- Inventory operations management

Production operations management is, at the core, the sequencing and execution of both operator and automation production steps. The sequencing is based on the product manufacturing requirements (how much is needed) and specifications (what is needed). Also included is the capture of all product- and production-related data. Benefits include the ability to rapidly modify a “shop floor” production schedule to meet current product demand, the availability of near real-time data to business systems, and a reduction in time for data entry time by interfacing directly with the automation systems.

Quality operations management is the automated monitoring of production and product data to ensure conformance to established specifications. Benefits include rapid identification of either process or quality issues. One major time savings is to be able to “review by exception” the critical parameters necessary to ensure a quality product. With all critical product and process data being tracked in real time against established specifications, the MES is able to present for review only those items outside established limits; leading to a quicker review and approval by quality representatives. Another time-saving aspect is the ability to automate equipment state tracking due to MES awareness of what products and batches are associated with each unit of equipment over time.

Inventory operations management is the tracking and movement of material through the production process, including items considered “in-process” or stored as a “warehouse item.” Included also is the automated tracking of “weigh and dispense” activities. Benefits include the detailed tracking and reporting of materials produced and consumed in near real-time, allowing for the rapid updating of production schedules to minimize downtime and reduce overall inventory.

Looking to the actual MES components, a key success factor is to design the MES hardware and software architecture to have the same level of availability as the facility automation systems. Avoid the temptation to design a facility based on the belief that the MES system will be unavailable, as this adds unnecessary complexity and cost. Systems designed for high-availability systems are available; simply use them.

No project is an island: the truth of an MES implementation and requirements

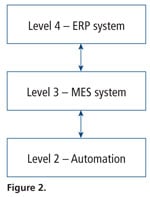

When describing the role of an MES, it serves, in part, as the "glue" between the "business" and "automation" systems (Figure 2).

As such, implementations are seldom done in isolation, with critical success factors being the need to understand the overall multi-level requirements definition process and establish effective communications between all organizations. As a start to understand the overall requirements, consider the major functionality of the systems at each level: The enterprise resource planning, or ERP, level systems focus on customer order demand, overall material and inventory planning, and financials. MES level systems focus on multi-production center sequencing conforming to a detailed schedule, material production and consumption, and the capture and analysis of production history. Automation level systems focus on production center equipment operation, control, and reporting. This is a very simplified view of the functionality at each level, but understanding the key items identified is critical for a successful integrated project.

Having now established that there are actually three co-dependent projects occurring during an MES implementation, we will now explore the interaction between each. Let us begin with a simplified model of each project consisting of requirements definition, build and test, and commissioning as shown in Figure 3.

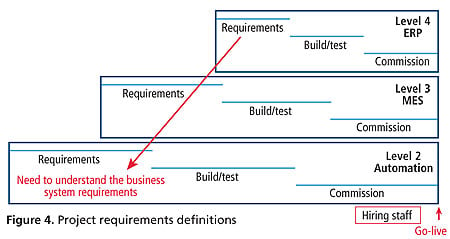

It would be great if projects at the ERP, MES, and automation levels had the same timelines and project implementation process. In looking at the typical project timing for each level, however, the actual integrated project appears more like Figure 4.

As can be seen, one of the major challenges is that, given the long lead time of certain automation projects, business-related requirements may not be fully understood until the automation team is in the middle of the build-and-test or commissioning phase of their project. So a key success factor is to understand the requirements from each level early enough in the overall project schedule to avoid major changes. Pay close attention to asking questions regarding the long-term information analysis needs of the business, as these usually translate to data capture and interfacing requirements.

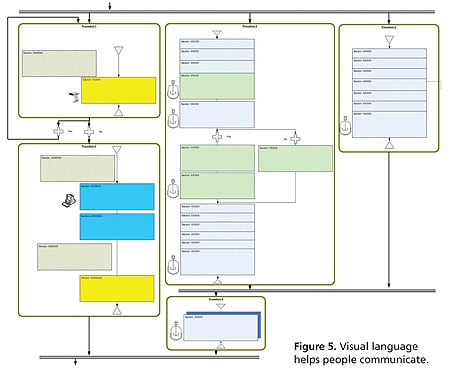

If you are fortunate enough to be implementing at a new facility, typically the operations staff is not completely hired until close to the actual go-live. You then have the fun of seeing experienced individuals review what is being delivered and then ask that it be changed to meet their needs for operational oversight. To minimize the chances of this happening, the key is to find experienced individuals to participate in the definition of the requirements and project delivery. We have been successful in having operations staff from other facilities join our project teams on temporary assignments. If you are implementing at an existing facility, plan on having individuals from operations join the team on a full-time basis. Chosen well, these folks know what is actually happening in the facility for defining the requirements and have the capability to bring the rest of the operations staff along with the implementation. Help these critical individuals in their discussions with coworkers by developing and using a "visual language" (Figure 5).

Describing MES and automation actions and operational sequences visually assists in the identification of parallel and co-mingled activities. On one project, we established a "team room" where we filled the walls with large drawings of the visual language and brought all the operations staff in multiple times to review and ensure that we had the process defined correctly prior to committing to coding. One side benefit was that we were able to identify several "unhappy path" scenarios where the production process might have deviated from the intended actions, allowing us to define and code these as alternative paths for the operations staff.

Additionally, consideration must be given to the organizational change impact of the delivery teams of multiple co-dependent projects. Automation and IT organizations must be closely aligned throughout the requirements definition and project execution processes through the use of robust change control that communicates and considers the impact of a modification at all levels and aided by the use of a common "cross-system" data definitions dictionary. Finally, it is important to understand and accept the implementation philosophy of each organization within the overall project. For example, the system environment and the development processes at the ERP level typically allow for rapid prototyping of several possible solutions prior to establishing the final business process. This leads to a desire for quick responses from the ERP team on questions regarding changes in requirements at the MES and automation levels.

Interfaces: The true joy of an MES implementation

Focus on the interfaces - simply stated: what interfaces are required; how is each interface triggered; and what data elements are contained within the interface. Document and reference these in your interactions with other system development teams. Avoid the temptation to try to understand the internal coding and data structures of each system and instead look at the "touch points" between systems. This allows you to build the necessary boundaries for the expectations of each system and avoid "functionality creep," where there is a loss of separation between the ERP, MES, and automation levels. Each level serves a distinct purpose with established business and operations processes; respect these differences by focusing on the interface. In addition, watch the number and level of complexity of the interfaces being established. It is easy to fall into the trap of trying to automate the interactions between systems to cover all possible scenarios, but this is not realistic. Learn to ask: "When (or how often) will this interface be triggered?" and then decide if the interface is necessary. Remember, there is a reason that most systems have a process for manual intervention; be prepared to suggest a manual process to avoid interfacing complexity of seldom-used actions. On one project, we decided that it was best to print a paper document for the movement of certain materials between two MESs due to the limited number of possible times this would occur.

Also seek to gain an understanding of the operational goals for the facility and the degree of operator interaction with the automated processes. Operator interaction can provide a "buffer" between automated actions, and it stands to reason that a greater desire to "automate" facility operations drives greater implementation complexity - usually appearing in an integrated automation/MES project as a need for increased interfacing. Further, as mentioned earlier, you may find yourself in the position of defining "automation" level requirements prior to there being either an MES or ERP team in place. In these cases, it is helpful to look at each system's focus as a predictor of what data interfacing may be required.

As a simple example, since the focus of an ERP system is customer orders, inventory, and financials, plan automation level interfaces to include:

- An interface to the automation system identifying a production job, sequenced to meet customer demand that includes the product to be produced, required raw materials, necessary parameters, and specifications

- An interface from the automation system on the completion of a production job - including start and end times, the amount of material produced and raw materials consumed, any byproducts of the productions process (including scrap and waste), any associated downtime during the production job, and quality indicators

Effective communications and accountability do matter

Consider the potential players in a major MES implementation today. Our current project includes an overall contracting team, seven major equipment/automation suppliers, six teams engaged in the MES development, and two ERP teams. And given the nature of software delivery today, these 16 teams are distributed across the world in seven different time zones. Since co-location is not an option, there is a need for an effective communications and accountability process that allows for rapid issue discovery and resolution. One effective method is to invest in an issues tracking system that is accessible to all individuals engaged in the project. The one we are using is cloud based and allows for the following: Overall statement and detailed description of the issue, the attachment of documents, entry of updates to the issue status with email notification to impacted individuals, and the assignment of an issue to a project milestone and issue owner. Simple in overall functionality, but with quickly customized reporting, we have accountability to an owner and are able to track open items to closure by a required milestone. This allows us to use focused conference calls with document display capability to allow for the rapid design decisions. Finally, we assign an individual to be the "issues moderator" to ensure that items are being addressed.

Successful automation, MES, and business systems integration are possible by focusing on the topics in this article.

About the Author Paul Brandenburg is a senior consultant with Brillig Systems. His focus areas are the delivery of MES projects and programs, developing implementation methodologies, and facilitating effective communications processes involving large geographically dispersed multi-cultural initiatives. He spent 28 years at Eli Lilly and Company in a wide variety of manufacturing facility and corporate IT assignments. He has a degree in electrical engineering and computer science from Rose-Hulman Institute of Technology and an MBA from Butler University.

Paul Brandenburg is a senior consultant with Brillig Systems. His focus areas are the delivery of MES projects and programs, developing implementation methodologies, and facilitating effective communications processes involving large geographically dispersed multi-cultural initiatives. He spent 28 years at Eli Lilly and Company in a wide variety of manufacturing facility and corporate IT assignments. He has a degree in electrical engineering and computer science from Rose-Hulman Institute of Technology and an MBA from Butler University.

Connect with Paul:

A version of this article also was published at InTech magazine.