The art and science of project management gives us useful knowledge and powerful tools and techniques to successfully manage complex projects in various areas. Nevertheless, it is necessary for project managers to combine all these benefits with a deep understanding of the industry-specific features of projects.

Industrial automation projects are sophisticated and have special aspects that should be considered for the execution to succeed. This article analyzes and shares some of the following points:

- industrial automation projects as a combination of construction and programming

- the multidisciplinary nature of automation projects

- lack of time reserves

- commissioning as a significant and particular part of an automation project

- importance of team member qualifications

- scope definition

- peculiarities of the startup phase

These peculiarities may be obvious to some people, but for others they may not be so easy to identify. This is especially true for project managers who are not familiar with industrial automation. Moreover, this is definitely not a complete list of specific aspects of automation projects, but rather insight into some of them. Full comprehension of these processes makes a project manager’s life a little bit easier.

Figure 1. Aspects of automation projects

Figure 1. Aspects of automation projects

1. Combining construction and programming

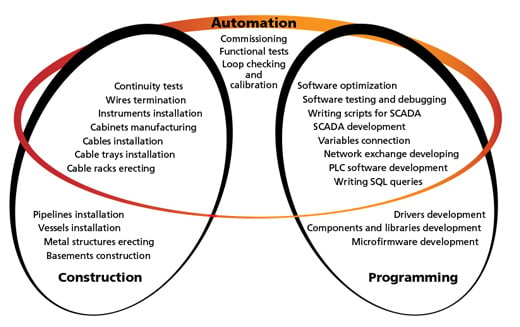

Automation projects include various types of activities in different areas, but the interdependence of construction and software development deserves to be highlighted. Both are important, but there is usually a lack of mutual understanding between the construction specialists (supervisors and installation engineers) and the programmers. It is clearly not an easy task to be proficient in both of these areas, but definitely valuable for a project manager.

Neither construction nor programming should be neglected, or the project could be in danger. For instance, all benefits of a sophisticated and advanced proportional, integral, derivative control could be devalued by an electromagnetic noise in the measurement circuit due to the wrong cable installation. Another example is a control loop with an accurate sensor and precise valve actuator that is completely useless because a programmer reduced the accuracy by using the wrong variable type.

Therefore, it is very useful for a project manager to develop his or her own expertise in these areas or at the very least have one member on the project team who is experienced in both areas.

Figure 2. Automation project as a combination of construction and programming

Figure 2. Automation project as a combination of construction and programming

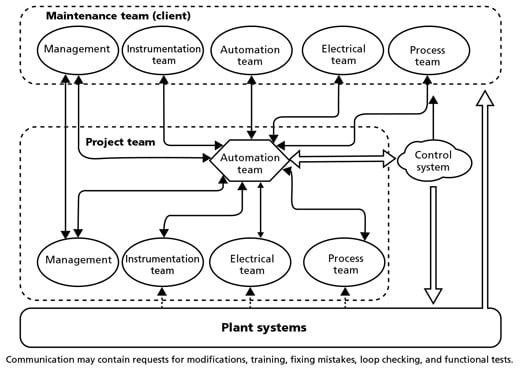

2. The multidisciplinary project

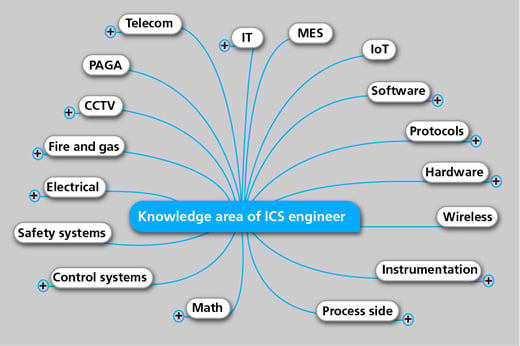

Automation and control projects are almost always supposed to be done with intensive cooperation from a large number of disciplines, such as instrumentation, electrics, fire and gas, process, and information technology. An automation engineer should be proficient enough in areas like the instrument range, type of signals, accuracy of sensors, and loop calibration methods. Furthermore, almost all the equipment (e.g., valves, motors) are energized by electrical panels that often have their own logic, automatic protections, parameters, and set points. The members of an automation team have to know all the important details of the electrical part of the project to avoid future problems.

For similar reasons, the automation project team members should not only be in charge of the automation, but it is also necessary for them to scrutinize all other parts of the overall project. To be able to do that, they must be proficient in other disciplines that are closely related to the overall process of an automation project. Otherwise, a misunderstanding between various discipline specialists and inevitable discrepancies between different parts of the project (electrical, instrumentation, fire and gas, process and automation) could endanger the automation project.

Figure 3. Multidisciplinary nature of automation projects

Figure 3. Multidisciplinary nature of automation projects

3. Automation projects lack time reserves

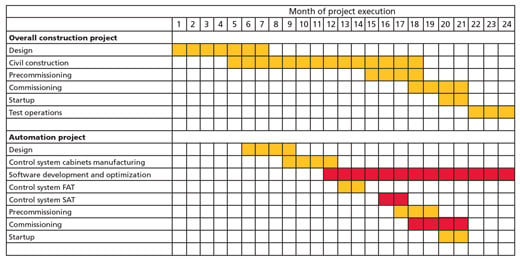

The vast majority of automation projects are included into bigger projects (construction/revamping), and the most significant parts of the work are performed at the very final stage of the overall project. Consequently, time scheduling and time management for automation projects are extremely critical, since the costs of delay are very high.

The closer to the startup time of the project, the more pressure there is for team members. In normal practice, the person who initiates and funds the project is referred to as the “client” even for an in-house project. Unfortunately, due to human nature, clients tend to blame all delays on the most recently involved party, which is the automation team in this case. A project manager, as well as the team members, should be ready for these stressful conditions and follow these tips:

- define the scope of work as accurately as possible

- define all the prerequisites for other mandatory systems and disciplines (e.g., completeness of civil and piping works and the electrical power supply)

- all blocking points from third parties (e.g., construction readiness, delays in deliveries, lack of the required client personnel) should be recorded and highlighted to a client (as officially and formally as possible)

- identify the responsible people, who preferably would accept the project’s deliverables and who would agree upon all of the acceptance procedures

- think how to keep the team members at a good performance level in such a stressful environment. Define overtime conditions and benefits.

Of course, it is better to avoid delays if possible. But it is the responsibility of the project manager to be ready to protect the team from unreasonable accusations of failing to meet construction deadlines. Moreover, a project manager should be ready to show and explain to a client very clearly all of the reasons for delays that are not part of the automation team’s responsibility.

Figure 4. Automation projects are usually a final part of construction projects and lack time reserves.

Figure 4. Automation projects are usually a final part of construction projects and lack time reserves.

4. Commissioning phase

This is the most significant and probably the most important part of the overall project, because during this stage almost all of the problems (mistakes in design, engineering, procurement, and installation) are discovered.

The automation project team members almost always become the most important part of the process at this stage. They are usually involved in troubleshooting with the other disciplines, and hence they have to share their time between their scope of work and solving some of the unexpected problems in other disciplines. It is important for a project manager to try to either avoid such distractions of the team members or at least get approval of an appropriate schedule with additional time available for the team members.

Some other features of commissioning are:

- Automation team members have to maintain a large amount of communication.

- Estimating the duration and the human resources required is not so easy, due to the high level of uncertainty, especially at the beginning of the project.

- It is very hard to reduce the duration of this phase simply by increasing the number of specialists.

- Team members who will be involved in the commissioning should be admitted and included in the project as early as possible (ideally at the design stage).

Considering these peculiarities helps to avoid typical problems like overloading team members with information and communication, lacking human resources at the final stage of the project, and underestimating time limits.

Figure 5. Communications of automation team during the commissioning stage

Figure 5. Communications of automation team during the commissioning stage

5. Team member qualifications

The cost of programmer mistakes is very high due to the time constraints of an automation project. There is simply not enough time during these projects to fix and repair the mistakes of underqualified engineers and programmers. The importance of the qualifications of the team should not be underestimated. It is better to spend money on preventing mistakes, which unqualified specialists could and most likely would cause in the later stages of the project, than spend it fixing them.

Besides all the required technical skills—such as knowledge of the specific control systems, expertise in related disciplines, and experience in the particular industry—a potential team member should be able to work under pressure and have basic knowledge of project management (e.g., ability to create and follow schedules, ability to communicate properly).

An automation team usually does not consist of a large number of members. Hence, a project manager should take a chance to establish a trustful and deep relationship with each member. This improves the team’s efficiency and motivation immensely.

If the project manager pays attention to the proper qualification and motivation of team members, he or she will avoid difficulties such as losing time for intensive software debugging, scope creep creating additions to the project, and lack of communication between all involved parties.

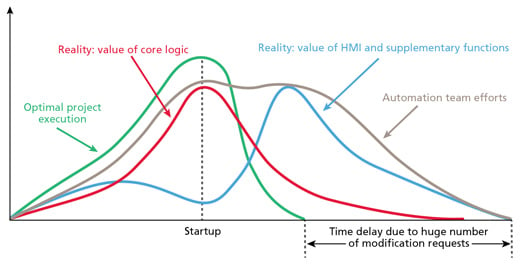

Figure 6. Optimal and real automation project execution

Figure 6. Optimal and real automation project execution

6. No project scope definition

Unfortunately, the scope definition for automation projects is often passed over as an outline. The technical specifications for the control systems often contain a lot of standard sentences and phrases (e.g., “in the most effective way,” “user-friendly interface,” “function should be automatic”) without any clear explanations of the meaning of these words. This creates an opportunity for various interpretations, and subsequently leads to misunderstandings, as well as troubles during the work submission and acceptance. Therefore, it could be very useful to define and to approve the technical specifications for systems, the scope of work, and especially procedures for acceptance as early and clearly as possible. Otherwise, a project team could face a situation where the client demands the work to be done regardless of the specifications, but no one knows what exactly it would mean, including the person that initiated and funded the project.

7. First the startup

Very often at the latest stages of the whole project, the only goal the client has is to start up, to push the “magic button.” Therefore other aspects of the project, such as safety, reliability, reporting, and the human-machine interface, are neglected or overlooked.

The most important drawback of this situation is that after a successful startup a client is usually not motivated to finish all of the remaining work quickly. Moreover, in this case the client has much more free time to study all the issues in detail, and as a result, there are many requests for modifications. The situation for a contractor is the polar opposite. He or she is looking forward to finishing the project as soon as possible. Therefore, if there is too much work remaining after a startup, it is most likely that the contractor will get stuck on the project. This is particularly true when the scope is not clearly defined, and a client generates more and more requests for modifications.

On the other hand, one of the possible benefits of this situation is that before a startup a client is much more flexible. The main objective at this phase is to finish the commissioning and startup, and not dive too deeply into the details of every specific issue. Therefore, it is a good opportunity to close as many issues as possible with as little effort as possible.

Generally speaking, it is better to avoid such situations, but if one has already occurred, then it is better to be ready and use its advantages.

Success journey

Automation projects have many more particularities than the ones mentioned here. Obviously, it is quite difficult for project managers to remember all of the points, but being aware of at least some of them could help them avoid disastrous pitfalls and mistakes. A wise, precise, and conscious approach to managing automation projects—with a clear understanding of specific features—makes the execution of the project smooth and predictable.

A version of this article also was published at InTech magazine.