Recently, there has been renewed interest within manufacturing execution systems (MES) as to the delineation and ownership of assets and processes with the plant between information technology (IT) and operational technology (OT). The topic has been touched upon in the recent book Manufacturing Execution Systems: An Operations Management Approach, published by the International Society of Automation (ISA).

Manufacturing Execution Systems: An Operations Management Approach

The purpose of this article is to delve deeper into this subject with more details and to provide a solution.

Defining IT and OT

First, let us define what IT and OT are. IT is concerned with the development, deployment, and ongoing support of assets that are responsible for the computer environment of an operation. This include the systems like email, PCs running Microsoft Office software, servers, clients, laptops, networks, computer security, printers, and backups for disaster recovery are all part of the daily operation of IT.

OT is responsible for the operation of the assets that controls the functions of the manufacturing plant floor. This includes programmable logic controllers (PLCs). The PLC-associated hardware, like control panels and their direct input/output devices (I/O) are also part of this responsibility. Even some of the programming and other support software have typically fallen under the responsibilities of OT.

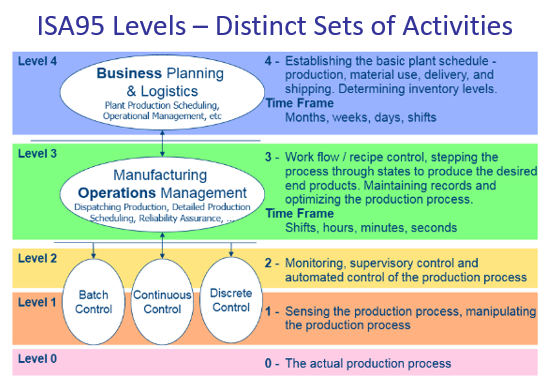

Where it becomes a concern is where IT and OT responsibilities overlap. Using the ISA95 model:

Source: https://www.isa.org/isa95/

We see that IT and OT, depending on the assets, can overlap on Level 1 depending on what networks are used, and also on Level 2 due to PC-based hardware assets used. Based on this, many manufacturers have discovered that either gaps in ongoing support coverage have occurred, or a redundant overlap of coverage has occurred. In a worst case scenario, certain items like system backups for disaster recovery (DR) were not done. When a disaster occurred, the software had to be manually reinstalled and reconfigured from scratch, which was a lengthy, time-consuming process.

Many manufacturers have reviewed this risk and have come up with solid plan to address it. Some of the most successful models to support proper IT and OT operation have defined the following:

IT Owns

- Network

- Hardware (servers, etc.)

- Security (firewalls, virus/malware prevention, etc.)

- Operating system (OS) and other server software

- Database (DB) software (current version of SQL Server, Oracle, etc.)

- DR process/configuration (backups, etc.)

OT Owns

- PLC hardware

- All associated PLC hardware (control panels, I/O devices, etc.)

- Process-specific software packages (RSLogix, RSLinx, Factory Talk, Siemens, etc.)

- Process-specific software packages configuration

- Process-specific software packages troubleshooting and support

This is just a suggested starting point. There must be application support in terms of coding if (or more likely when) customization is added. In addition, there must be upgrade support to the application supporting a process. Upgrades will be handled by the organization that owns them, and depending on the application, it can be either IT or OT. There will be some IT specifics to application config, like security archives and ETLs for data warehousing. The application config that is directly responsible for support of process should be owned by OT. This handles the technical parts for hardware and software.

Working Together

The greater question remains the alignment of the business processes supported by both IT and OT. As with other aspects of MES, the business processes are supported, but these systems must also be understood in order to ensure that all aspects of the systems used properly support the processes involved. This demands even greater collaboration between IT and OT. In many cases, IT and OT have been operating in their own functional silos, and only minimal cooperation and collaboration has occurred between these two operational organizations.

To facilitate the smoothest support of MES and MES-supported business processes, not only should there be agreement as to who supports the elements of hardware and software, greater operational cooperation and collaboration needs to occur in all phases—from system requirements and development to implementation to ongoing support. Manufacturing leadership will need to determine the best business operations model for both IT and OT to work together to ensure common understanding, so that no gaps in support and no redundancies occur. Redundancies can be just as detrimental to an organization as support gaps are—due to work being missed because an assumption was made that the other team would do it, or work being executed that was partially redundant, leading to confusion over which effort is the correct one.

In order to realize the full benefit of MES operations, and also to increase the value to the organization and to lower overall costs, alignment with the different partners in the organization must occur. Technically, it starts with the IT and OT organizations.

To purchase the book Manufacturing Execution Systems: An Operations Management Approach from ISA Publishing, visit the ISA Store.