This post was authored by Debashis Sadhukhan, process controls system manager at NASA, and John Mihevic, retired DCS control system manager.

At the NASA Glenn Research Center (GRC) in Cleveland, Ohio, existing programmable logic controller (PLC) input/output (I/O) was replaced with distributed control system (DCS) I/O, while keeping the existing PLC sequence logic. Until about the year 2000, the GRC’s central process system (CPS) distributed control system used PLC I/O to remotely control and monitor process equipment.

Until about the year 2000, the GRC’s central process system (CPS) distributed control system used PLC I/O to remotely control and monitor process equipment.

For many years, these devices were the core of process I/O at the facility. As new industrial control and communication technologies emerged, the benefits of improving traditional I/O schemes for newer approaches became attractive. For this reason, NASA recently replaced several PLC I/O with DCS I/O hardware, while keeping the PLC processor in order to evaluate the interoperability of this new technology. The new technology has improved throughput speed from the I/O to the operator screens.

There are now many attributes to a data point, including diagnostic capability and calibration.

Plant description

The CPS at NASA Glenn provides combustion air to 1,250 pounds per square inch gauge (psig), altitude exhaust (to 90,000 ft), atmospheric exhaust, refrigerated air (to –90°F), cooling tower water, and service air for the major wind tunnels and propulsion test facilities at Glenn. The CPS consists of 20 miles of process piping and 600 valves to connect the above systems to the various test facilities. A DCS/PLC/pressure and surge controller system consisting of nearly 100 proportional, integral, derivative (PID) control loops and more than 12,000 I/O points monitors and controls the vast amount of equipment across the facility. More than 12 miles of dual-redundant data highway cable is installed to interface with the control/data system for these essential services. Historically, the equipment for controlling and monitoring the process consisted of a PLC processor and its associated I/O distributed near process equipment. The PLC communicated to the DCS controller via the Modbus RTU protocol. The DCS controller then communicated to the operator console via a proprietary data highway network.

Reasons for conversion to DCS I/O

Although the existing I/O was adequate at one time, the need for its replacement became more apparent as the technology changed. While the existing I/O was readily available in the 1990s, more recently parts for repair and replacement were difficult to find. An upgrade to the new replacement PLC I/O was available, but it provided none of the benefits of the DCS I/O. The DCS I/O had much faster speed and a “quality status,” which was not available on a Modbus RTU serial link with a transmission rate of 19,200 baud. The choice was to either replace the entire PLC system with the DCS system at one time, which required massive logic conversion and testing, or perform a two-phase implementation approach. The first phase would replace the PLC I/O with the DCS I/O. Then the second phase would involve converting PLC logic to DCS logic. The split approach was chosen to minimize downtime and prevent a complicated check-out process.

Hardware installation

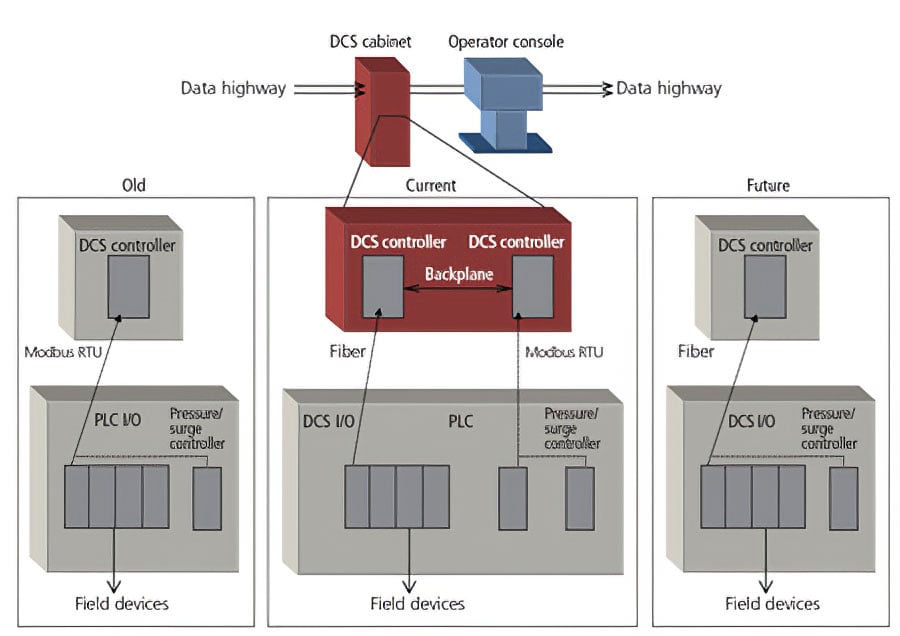

The components for this application include a new DCS controller, a DCS I/O, and new 24-V dual-redundant power supplies for the I/O. The PLC processor remains and communicates strictly to the old DCS controller, which in turn communicates to the new DCS controller that talks to the new DCS I/O. As with the old system, the primary function of the new system is to provide process control of the equipment via the DCS, which is made available to operators at a remote location. The basic system architecture is shown in figure 1.

Figure 1. Basic system architecture

Figure 1. Basic system architecture

In all cases, existing wiring could be reused as part of the new scheme. The new I/O was mounted in the existing I/O space. The old field wires were terminated on the new I/O. The 24-V I/O power supplies were installed in an existing cabinet. A new DCS controller, connected to the new DCS I/O via fiber, was installed in the same cabinet as the old DCS controller. The new DCS controller communicates to the old DCS controller via a backplane that provided a local control highway within the cabinet.

Software installation

The software for this application includes DCS controller software that allows communication between the old DCS controller and the new DCS controller. The PLC receives the necessary data for sequence logic from the new DCS controller. No field I/O connects to the PLC. All PID algorithms are processed in the new DCS controller and pressure and surge controllers, which communicate to the old DCS controller via Modbus.

System architecture

The new DCS I/O is installed in the current PLC I/O location. Wires from the field were removed from the PLC I/O and terminated on the new DCS I/O. The new DCS I/O connects to the new DCS controller via a fiber optics network. The old DCS controller utilizes a custom foreign device interface “C” program and Modbus RTU protocol to communicate to the PLC. The old and new DCS controllers communicate with the operator console via a proprietary data highway.

One of the powerful features of the new I/O is the troubleshooting capability via the DCS diagnostic. It also provides “bad quality” status on the operator console in the case of signal failure. With the old PLC I/O system, analog data was converted to digital counts (0–4095). The problem with this conversion is there is no “under” or “over” range. The live zero of a 4- to 20-mA signal is lost. This is a very important feature.

Before DCS and human-machine interface (HMI), when pushbuttons and meters were the interface to the operators, “zero-based” meters—whether voltage or current—were common. The problem with zero-based measurement readouts is the inability to distinguish a true zero reading from a failed transducer. With the PLC there was also no way to distinguish a zero reading (4 mA = 0 counts) from a failed transducer (0 mA = 0 counts).

High-speed PID loops (100-ms sampling time) and analog data used for measurement and alarming is processed through the new DCS I/O. Only sequence data is processed through the PLC processor.

Testing of new I/O

Some problems were encountered while commissioning the new I/O installation. One of these involved minor wiring errors on the drawings, which made it hard to find the field devices for HMI screen-to-field device point testing. This was a relatively easy fix. Verification of the drawings before demolition, although time consuming, would have lessened downtime and would have resulted in a net saving of time. Having the same PLC logic reduced troubleshooting, by isolating errors to the I/O cabinet.

General evaluation

Although the PLC I/O was sufficient by prior standards, the organization believed that the newer industrial technologies were at the very least worthy of a trial in the CPS application. No historical data is presented here to detail the performance of the traditional PLC I/O system versus the new DCS I/O system, but years of experience with them does give one an overall appreciation for the strengths and shortcomings of the vintage technology. All said, this type of I/O has, except perhaps in less demanding roles, outlived its usefulness in modern control and data acquisition systems.

Thus far, the new I/O is very accurate. There is no indication of failing or drifting from the original calibrations. However, one drawback to the system is that for the present the signal update time in the PLC is 4 to 5 seconds compared to 2 to 3 seconds with the old I/O. However, the signals that are not needed in the PLC are scanned at the field device and available to the operator console in 2 seconds. The 4- to 5-second delay is due to the transfer rate from the new I/O to the old DCS controller in addition to the field device interface (FDI) of 2 to 3 seconds. This update rate is tolerable, however, for these noncritical process sequence points. With the new I/O, the FDI is gone, therefore eliminating the overhead of the C program and the 19,200 baud serial transmission rate. The time required for the new DCS controller to scan all its associated I/O is 250 milliseconds.

Future applications

There is a plan to convert the PLC program to a DCS controller program, thereby reducing two controllers (the PLC and the old DCS controller) to one controller and reducing the 4- to 5-second response time for sequence points to 2 seconds.

Benefits

The new DCS I/O provides simple installation, more accurate data, and improved diagnostic capability compared to the old I/O systems at GRC. Therefore, in the long term, we foresee the utilization of DCS I/O as an enhancement to our facility DCS and a benefit to users.

About the Author

Debashis Sadhukhan, process controls system manager at NASA Glenn Research Center (GRC), has been employed at GRC since 1991 and is experienced in integration of DCS and PLC systems. He is currently president of the ISA Cleveland Section and bulletin editor. John Mihevic was DCS control system manager at GRC until his retirement in 2007.

A version of this article also was published at InTech magazine.