What Is RTLS?

A real-time location system (RTLS) is a type of indoor positioning system that is gaining popularity in industries for improving efficiency, productivity, and safety. Using these systems, we can accurately track and locate assets and people inside industrial premises. RTLS is capable of achieving centimeter-level accuracy. Markets and Markets forecasts the RTLS market to grow from USD 3.186 million in 2018 to reach USD 8.792 million by 2023, at a compound annual growth rate of 22.5%.

Conventional GPS systems won’t provide accurate location information inside industrial premises due to the inability of GPS signals to penetrate through construction materials. GPS devices are much more costly, complex, and consume more power in comparison to Bluetooth Low Energy (BLE) technology. Depending on the data transmission and power consumption, the BLE tags can achieve a battery life of seven years.

Components of BLE-Based RTLS

An RTLS is comprised of BLE tags, BLE anchors, and BLE gateways with Wi-Fi connectivity and an edge computer to gather and analyze the received data.

BLE tags transmit BLE signals at definite intervals. The BLE tags come with multiple sensors built in, such as 3-axis accelerometers, temperature sensors, shock sensors, light sensors, and so on, for ambient condition monitoring.

BLE anchors receive the signal transmitted by BLE tags and calculate the RSSI value, angle of arrival (AoA), and angle of departure (AoD).

BLE gateways act as the master and collect information from associated BLE anchors. These gateway devices have Wi-Fi connectivity for communicating with the edge computer.

Why BLE-Based RTLS?

BLE-based RTLS gives better accuracy and is relatively cheap when compared with other existing technologies. Small coin-sized BLE tags are available that have a long battery life.

|

Item |

Accuracy |

Anti-Interference Performance |

Power Usage |

Data Rate |

Coverage |

Battery Life |

Cost |

|

Active RFID |

Good |

Good |

Medium |

Low |

Good |

Good |

Medium |

|

BLE (Bluetooth 5.1) |

Very Good |

Very Good |

Low |

Medium |

Good |

Excellent |

Medium |

|

Wi-Fi |

Poor |

Good |

High |

High |

Very Good |

Poor |

High |

|

ZigBee |

Very Good |

Very Good |

High |

High |

Good |

Average |

High |

|

UWB |

Excellent |

Excellent |

Medium |

Medium |

Good |

Good |

Medium |

|

GPS |

Good |

Good |

Medium |

NA |

Excellent |

Average |

Very High |

Architecture

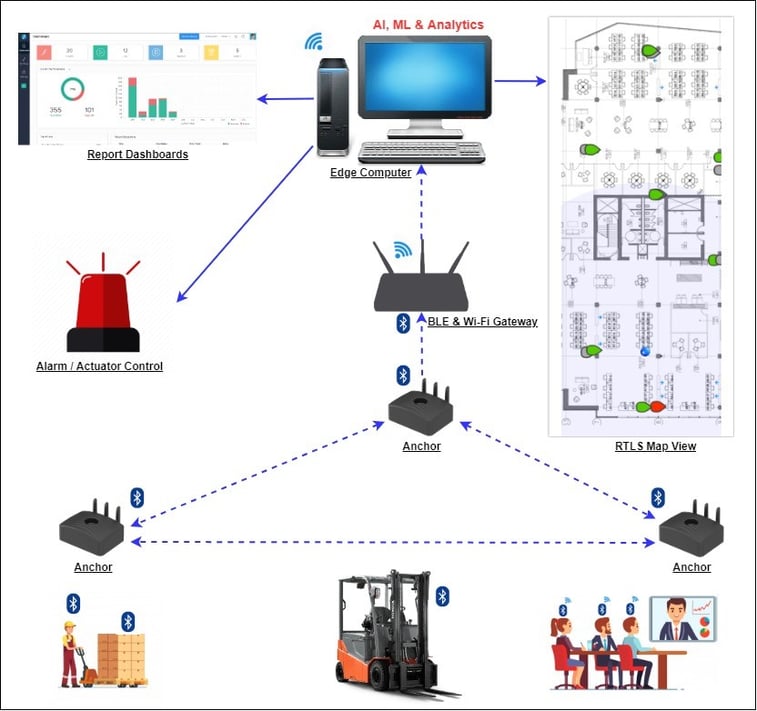

BLE tags are attached to the personnel, forklifts, and assets that need to be tracked. The BLE tags will transfer signals along with the sensor data to the nearest anchors at a one-second (configurable) interval.

These data will be evaluated by the anchors based on the RSSI value, angle of arrival, and angle of departure. Anchors are always placed at fixed locations. They communicate with one another through mesh topology.

The data, along with the position coordinates of the tags, are transferred to the BLE and Wi-Fi gateways. The gateways further transfer the accumulated data to the edge computer. All positioning, AI, ML, and analytics will be run on the edge computer. The computer will also perform control/alarm actions, and it can present report dashboards and live monitoring maps.

Tags come with built-in push buttons that can be configured for intelligent access control to specified areas. This system can be integrated with the alarm management system and existing security cameras to improve security. Enabling cloud functionality to the edge computer will help the operator access the information remotely.

Diagram of RTLS architecture

Diagram of RTLS architecture

Social distance monitoring can also be achieved using this system. If two or more people come in contact, vibration/audio-based alerts can be sent to the respective tags. The vibration/audio alert will automatically reset once they start keeping the safe distance. All reports can be monitored through the respective web/mobile application developed.

Upon fully implementing RTLS, industries will benefit in the following ways:

- Live monitoring of all assets and personnel in map view

- Automatic attendance system

- Productivity tracking of individuals and assets

- Fuel usage pattern of forklifts and their efficiency can be analyzed

- Effective use of forklifts by identifying and using the nearest one available

- Collision avoidance between employees and forklifts

- Time consumed for asset identification can be reduced

- Time reduced for asset identification in inventory and warehouse management

- Improved safety and security

- Intelligent access control

- Integration with existing security cameras, which further improves security measures

- Social distance monitoring and contact tracing

- Theft control

RTLS Applications in Industries

- Control of inventory and management of work in progress and employee productivity calculation in the manufacturing industry

- Supply chain and warehouse industry management

- Asset tracking and safety improvement in the oil & gas industry

- Monitoring patients and tracking of medical equipment in the health care industry

- Advertising in the retail market industry

- Student and staff tracking in the education industry

- Live location tracking within the mining industry

- Continuous tracking of parts, machines, and people involved in the manufacturing process of the automotive industry

Interested in reading more articles like this? Subscribe to ISA Interchange and receive weekly emails with links to our latest interviews, news, thought leadership, tips, and more from the automation industry.