This post was authored by Tony Christian, director of Cambashi, a global industry analyst and consulting firm

In many sectors of the manufacturing industries, especially those considered "high tech," developing and introducing new products faster is seen as the primary driver for growth, while managing changes to products is seen as the top challenge for maintaining quality.

That is, product change is a source of improvement and opportunity, and, at the same time, a source of complexity that introduces quality problems. Automation enhances quality at the local facility level. It is also critical to the continued prosperity of many sectors of manufacturing in the Western economies in terms of productivity. However, it is often viewed through the narrow lens of "making things in this facility more efficiently and in a more repeatable way."

Even exploiting automation technologies fully to achieve improvement at the local plant level often requires consideration of an integrated web of processes and practices. However, many industries that have embraced high levels of automation in their own facilities have to cope with lengthy and complex supply chains spanning a number of organizations in a number of countries, or perhaps even a worldwide set of relationships more appropriately characterized as a supply network.

The different stages of the product lifecycle are likely to involve different participants in different roles; for example, a development partner with advanced prototyping facilities would likely be replaced by a facility with mass component production capabilities once the product was finalized.

The ideal is therefore to consider automation technologies in the context of optimizing the operational performance-speed of product flow, inventory levels, and quality-across the whole network throughout every product life cycle. This covers not only steady-state production, but also all the changes. At this broader supply-chain level, the product lifecycle problem extends to inter-organizational processes and information.

As a result, the search to maximize benefits-for example, by optimizing "where to make" decisions or when to invest in new manufacturing technologies-often founders on the difficulties of communicating information, the processes which by nature are more opaque than tangible material movement, or manufacturing process steps. Nevertheless, inter-organizational processes and information can be critical, and ensuring that they are fit for purpose, especially at the inter-organizational level, is a complex problem that demands effective information technology (IT) integration across the value chain, including supply chain and automation.

The requirement for effective communication starts at the early stage of the formation of the supply chain, that is, in the product design activity. Examples of activities that are both nonvalue adding and potential sources of error are creating different versions of design information simply for communicating changes to other members of the design network and the inefficiencies involved in manually updating information in multiple places to reflect the latest design changes.

This is where the concept of product lifecycle management (PLM), which has its roots in product data management and has evolved to management of the full life cycle, originated. However, the benefits of effectively using information go way beyond "keeping everyone on the same page." PLM systems are now widely exploited for access to previous design information, allowing organizations to properly evaluate existing components or subsystems in the new product.

Integration between design and manufacturing at the product development stage, now much greater than it was when groups did not work cooperatively and the "over-the-wall" problem was common, offers even greater possibilities. In an environment in which constant product innovation and speed to market must go hand in hand with stringent product quality requirements-in today's world, that means most manufacturing sectors, from automotive to medical devices-the ability to consider the manufacturing options early in the product development stage is of huge benefit.

This should not only involve considering the technology required, the cost, and so on, but also include an analysis of how changes to the design may deliver worthwhile benefits in terms of manufacturing and whether such changes would be acceptable.

Improving manufacturing

The role of automation is a major aspect of improving manufacturing. Current technology enables a digital version of the manufacturing facility to be tested in its entirety for production of the new product before starting manufacturing-or if the product requires new manufacturing facilities, prior to their physical creation. The core manufacturing processes (e.g., machining, robotic operations) can be simulated in significant detail using specific technologies like work-cell design and simulation software that allows users to develop, simulate, optimize, validate, and program multi-device robotic and automated manufacturing processes.

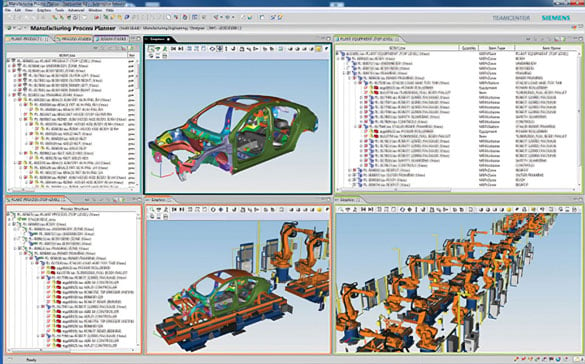

Automation engineers create full-action simulations of complete manufacturing cells and systems within a three-dimensional environment. In this way, the processes can be optimized, and ideas for improved manufacturing ability fed back to design. Subsequently implementing design changes to improve existing and new automation facilities yields maximum benefits from investments. In fact, the technology now goes further, allowing organizations to simulate an entire manufacturing operation, including the materials handling and logistics aspects (figure 1).

Figure 1. An entire simulation of an automotive production line provides insights for better manufacturing and automation.

Figure 1. An entire simulation of an automotive production line provides insights for better manufacturing and automation.

Optimizing facility operations

Experimenting with the digital model in this way enables the overall facility's operation to be optimized, and many problems that would have required interruptions in manufacturing operations (which of course can be expensive) to be fixed in the virtual world. That is, by including information regarding the manufacture of components and subsystems in the PLM environment, it becomes possible to review and assess the manufacturing side of the picture early in the product's life. This aspect of PLM is therefore highly relevant to automation engineers.

First, given the cost of most automated production facilities, designing the automation systems with a view to maximizing throughput is a key consideration; but second, there is usually a trade-off between cost and throughput on the one hand and flexibility in terms of product variety on the other. The ability to experiment with different automation configurations in the context of the anticipated new product flow is therefore of huge value, not only in terms of consideration of the manufacturing process early in the design phase for a given product, but potentially in terms of optimizing the facility across a range of products.

The benefit is enhanced further if the knowledge base of production information extends across the supply chain, supporting the analysis of where to carry out each task. This is the role of PLM. It integrates all parties involved in the whole product lifecycle, from ideas and research to manufacturing and in-field support-means that the technology must be available to a wide range of users, certainly wider than the traditional design engineering user base.

The good news is that the leading PLM providers recognize this and have made substantial progress in recent years toward this goal, including making PLM technology more affordable by exploiting infrastructure and hardware developments like cloud computing and the capabilities of mobile devices.

There is one more aspect, however, that is important to automation engineers, namely the need to manage the software component of automated production technologies. In general, software has been managed outside of the classic PLM environment, but recently the major PLM vendors have begun to incorporate specific capabilities for software.

As a result, the leading PLM solutions now integrate design systems with the control and process information, allowing engineers to collaborate on establishing the design options for the optimum combination of product capability and manufacturing processes.

About the Author

Tony Christian is director of Cambashi, an industry analyst and consulting firm focused on the use of IT in industry. He brings a wide range of experience in engineering, manufacturing, energy, and IT. Christian’s early career was in technical research and development roles, after which he moved into computer-aided engineering. More recently, he was a director of the U.K. Consulting and Systems Integration Division of Computer Sciences Corporation, leading a consulting and systems practice for manufacturing industries, and then services and technology director at AVEVA Group PLC, where he was responsible for all product development and the company’s worldwide consulting and managed services business. He has a B.S. in mechanical engineering and an M.S. in engineering acoustics, noise, and vibration from the University of Nottingham.

A version of this article also was published at InTech magazine.