This post was written by Tapio Talvitie and Martin Ottosson of ABB.

Tension controls are crucially important, both for the runnability of the machine and for the overall quality of the product. However, this control is quite often executed imperfectly or even incorrectly because of poor design or engineering. Many times the selected components themselves are good, but they are still incorrect for the specific application, or the application can be derailed by the wrong type of installation. More often than not, the controller tunes the web tension based on a poor and heavily distorted signal, or the controller output is not used in an optimal way.

The typical requirement for a tension control accuracy is 1 percent at constant speed and 2–4 percent in speed changes, based on the measured signal. But it is not unusual to see a tension signal distortion to be about 10–200 percent off. An independent reference may be difficult to obtain, and so the degree of distortion is evaluated indirectly.

There are many factors that can undermine good quality tension control; these must be accounted for when designing your application. Here is a bulleted list of things to consider when planning a tension measurement and control application. The list may not be comprehensive and is just headlines, without further explanation of the deeper meaning, as each one of those can include information worthy of a separate article. The team we work with has a long history of researching, working, and solving these issues.

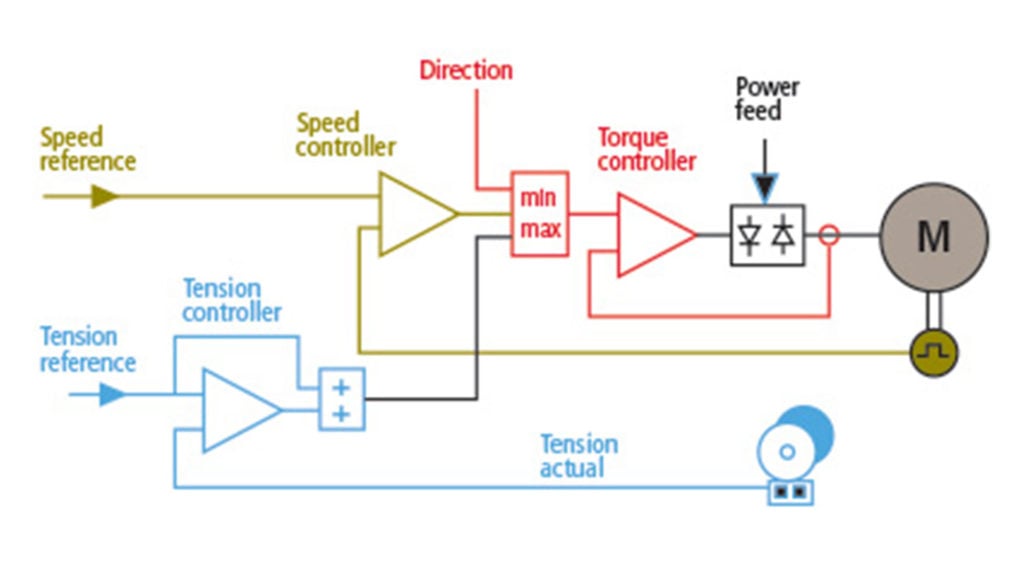

Tension-controlled center drive

Tension-controlled center drive

1. Environment for the tension measurement

- Temperature (in load cells, in supportive structure, radiation from side)

- Stiffness of supporting structure

- Roll balancing (vibration)

- Roll surface (slipping or gripping)

- Driven or nondriven roll

- Single or parallel motor within inverter unit, applied in measurement roll

- Roll inertia

- Roll weight

- Different motor coupling types (e.g., universal shaft, teeth coupling, flange coupling, belt)

- Bearing housing supports

- Threading rope belt force isolation

- Web wrap angle around roll

- Force direction of the web versus force measurement and tare weight

- Optimal place of measurement for the control

2. Tension measurement

- Type of load cells (e.g., quality, robustness, overload capacity)

- Number of load cells (on one side, on both sides, multiple cells with or without roll ends)

- Load cell mechanical and electrical installation

- Load cell installation direction (horizontal, vertical, angle)

- Load cell dimensioning (according to measured force, overload, and tare)

- Calibration methods and optimal scaling

- Pros and cons in signal filtering

- Stability in signal offset, ways to correct

- Tension profile and tension difference when there is more than one load cell

- Third-party measurements (e.g., air cushion pressure in turn dry, web slack measurement)

3. Tension control

- Tuning parameters (proportional, integral/proportional, integral, derivative and filtering)

- Controller logic (e.g., switch points, limits, ramps, web threading)

- Problem in web moving sidewise, typically in speed changes

- Acceleration and deceleration of the machine

- High-speed effects in tension on speeds greater than 2000 m/min (material air friction, centrifugal force)

- In high speeds do we control tension (stress) in the web or web grip (force) to the roll?

- Controller output effect on the speed or torque reference

- Acceleration compensations to help speed and tension controls

- Motor torque or roll inertia is distorting the measured signal

- Controller logic in dynamics (e.g., doctor blade on/off)

4. Overall system

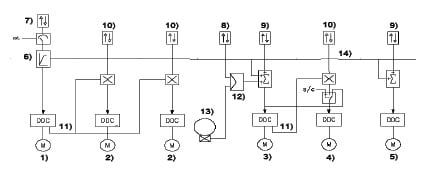

- Speed reference chain (chain, branches)

- Managing multiple (cascaded) tension controls

- Other guiderolls’ influence on the overall system

- Slip of roll controlling the tension

- Handling variable web width (e.g., salvage winder)

Web tension control is used to improve web handling during machine speed changes and to compensate for machine directional variations of the paper. Because tension control is the outmost control loop, the response time is slow compared to that of torque control or speed control. Typically, response time of tension control is about 10 times slower than that of speed control, in the range of 10–30 s. Thus any fast process disturbances influencing the web tension, such as coating beam closing and opening or an excessive paper sheet moisturizing effect, are compensated for using a separate feedforward effect on the drive’s speed or torque reference.

Example of a part of a paper machine’s speed reference chain

Example of a part of a paper machine’s speed reference chain

Short summary

Tension can exist in material, which is somewhat elastic. Optimal tension improves the runnability of the machine. Tension that is too high can have negative side effects, seen before the material breaks, so be reasonable. One of the side effects is that high tension can permanently deform the material so it loses part of its elasticity for good. In every phase of post processing the product requires typical tension, which is higher than used earlier for the material. So be careful not to distrain the whole capacity of web elasticity too early, so as to aggravate any later processing.

Last, but not least, you can hardly live without good quality tension controls. But to be honest, if the machine is well tuned and the state of changes properly compensated for, the tension controls are more or less passive observers in the background, doing minimal work. Heavy corrections from tension control indicate either poor tuning of sectional drives or insufficient compensations—or, in the worst case, controller measures based only on a distorted tension signal, as a false positive. To tune the machine well, first you need a good quality tension signal as a base for your work. Tuning tension controllers may be a later or last point of interest, though, as an overall and outermost loop of control.

Advances in load cell system technology can help improve the reliability and accuracy of these applications.

Accurate tension key to quality

Accurate web tension measurement and control is essential to achieve high levels of quality and productivity. Modern load cell systems provide the reliability and performance required for these applications, and they are designed to function well in harsh environments.

Knowing what the tension actually is at various key points in a machine or process line is fundamental to ensuring high quality and efficient operations in all types of web converting processes. Web tension measurement and control are equally important in converting, as well as film, foil, textile, and nonwoven manufacturing.

Essentially it is the ability to dynamically control the mechanical tension in any material being processed at any point in the process phase while it is accelerating, decelerating, or at constant speed. It is required in any web handling and converting machinery to achieve production with both high and consistent quality, to achieve high productivity with the minimum of unscheduled production stops, and to increase the machine speed.

Important requirements for reliable web tension measurement and control include long-term stable sensitivity—the secret to good and reliable repeatability—robust construction to withstand real production environments, recalibration-free load cells minimizing maintenance costs, and user friendliness to minimize the time for setup and commissioning.

Improved productivity

Web tension as a process value is measured and controlled to protect machines and machinery and leads to improved productivity and product quality. Tension that is too high can cause damage to deflector rolls and roll bearings, resulting in unplanned machine stops, stretching of the web, change in the width, and ultimately snapping of the web, in addition to “wound roll” defects such as crushed cores, starring, and edge cracks.

On the other hand, tension that is too low often causes defects, including web wrinkles where the web is not stretched sufficiently over deflector rolls; web skid marks coming from the rolls, usually because the web is not able to transfer sufficient torque to idle rolls or pick up torque from driven rolls; and poor reel quality, causing ongoing problems in the follow on processes and the possibility of telescoped reels.

Unstable tension is caused by length and width variations in slitters and sheeters or curled material in laminating processes.

There are a number of high-performance systems available today that use digital tension electronics to provide tension measuring options and performance superior to older technology. Newer technologies that use a measurement principle based on the magnetoelastic effect are not contingent upon physical movement or deformation, providing the sensitivity of load cells with extraordinary tolerance to overloads and virtually no built-in limit to the number of load cycles. In addition, newer load cell technology is easier to maintain. When the web breaks, it is not necessary to spend several hours recalibrating the load cells or replacing them because they have failed, so the lines are quickly up and running again, minimizing downtime. Digital electronics are easy to configure, program, and troubleshoot, and users benefit from access to improved data via the display.

These load cells can deliver very stable tension measurement over time; the display is easy to operate; and there are many good functions to take advantage of. These robust load cells are designed to work well in severe production environments with high humidity and significant differences in temperatures; they provide reliable and stable measurement.

In this rugged environment, the load cells are designed to withstand an impact without breaking (e.g., when the maintenance people climb up and down the machine, one of them can step on a load cell without breaking it).

Closing thoughts

Understanding what influences accurate web tension control and then taking the necessary actions to achieve it are critical to maintaining high product quality, as well as to optimizing overall machine performance. Through careful planning and application design, and by implementing newer measurement technologies for these applications, users can improve overall process and product quality, improve machine and process performance, and avoid costly downtime and minimize off-specification product. The initial investment in the planning stage will pay off handsomely for many years to come

About the Authors:

Tapio Talvitie is product manager in winding applications of PM Drives, working for ABB in Finland. He has 30 years of experience with sectional drives in the paper industry, working as commissioning engineer, SW application engineer, lead engineer, and now as research and development developer. He works on paper machines, winders, on-line and off-line coaters, calenders, and reelers, with a special interest in control philosophies.

Martin Ottosson is marketing communications manager for ABB product group force measurement and ABB global media relations manager for measurement and analytics. He has more than 20 years of experience in the measurement products business, mainly with force measurement in the metals and paper industries. He is author of about 100 application stories from customer sites worldwide.

A version of this article also was published at InTech magazine.

Click here to read this article on web tension control at InTech magazine.