This article was written by Jim Colby, senior business development manager for the electronics business unit of Littelfuse, Inc.

The original Industrial Revolution marked the transition from making things using human and animal power to making them with machines by harnessing water and steam power. The ability to use electricity for the mass production of goods made the second Industrial Revolution possible; the third came from using computers to automate production processes. The fourth Industrial Revolution marks the transition from “dumb” machines (i.e., assembly lines, standalone automated painters, welders) to ones that are made smarter and self-configurable. They incorporate sensors and processors and, more importantly, are connected together and to the operations center via the Industrial Internet of Things (IIoT).

Sometimes known as Industry 4.0, the fourth Industrial Revolution has the goals of making production more efficient, cost-effective, and flexible and delivering a better product to the customer in less time. However, the increased connectivity that the IIoT brings to factory automation systems also makes these systems particularly vulnerable to electrical damage from a variety of threats. These threats include electrostatic discharge (ESD), electrical fast transients (EFT), cable discharge events (CDE), lightning-induced surges, as well as system-induced voltage transients that occur when large motors turn on or off via both data and power connections (e.g., industrial Ethernet, Power over Ethernet [PoE], CAN bus, RS-485, Profibus and fieldbus).

The engineers designing and implementing automation systems in industrial settings need to be aware of the appropriate circuit protection solutions, such as transient-voltage-suppression (TVS) diodes, TVS diode arrays, gas discharge tubes, and protection thyristors, that can help reduce (or eliminate) the risks involved. This article is an overview of circuit protection solutions that are particularly appropriate for a variety of industrial automation applications and their advantages for ensuring the reliability of the systems driving the factories of the future.

Industrial Ethernet

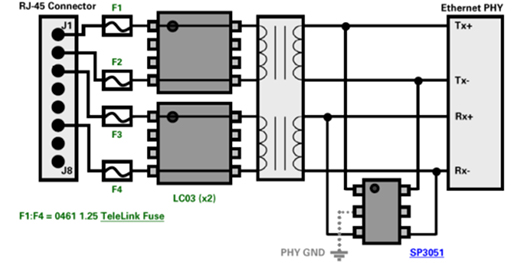

Industrial Ethernet (IE) combines standard Ethernet protocols with rugged connectors and high-temperature switches. Components used in industrial applications must be able to withstand temperature extremes, humidity, and vibration significantly beyond the ranges for equipment intended for installation in typical office environments. Industrial Ethernet networks must interoperate with both current and legacy systems and must provide predictable performance and maintainability. In addition to physical compatibility and low-level transport protocols, a practical industrial Ethernet system must also provide interoperability of the higher levels of the open systems interconnection (OSI) model. An industrial network must provide security both from intrusions from outside the plant and from inadvertent or unauthorized use within the facility. Figure 1 illustrates one approach to indoor long-haul data-line (not PoE) protection against lightning-induced transients, ESD, EFT, CDE, and power faults. It is appropriate to use in a factory automation environment.

Figure 1. One approach to indoor long-haul Ethernet data line protection against lightning, ESD, EFT, CDE, and power faults. The four data lines shown (Tx± and Rx±) are protected against intrabuilding lightning transients. The LC03 TVS diode array diverts the majority of energy away from the transformer, but any common mode energy that does get coupled across the transformer interwinding capacitance is diverted to GND by the SP3051 TVS diode. This component can be connected to ground on the PHY side of the transformer because the IEEE 802.3 isolation requirements are met by the transformer itself.

Figure 1. One approach to indoor long-haul Ethernet data line protection against lightning, ESD, EFT, CDE, and power faults. The four data lines shown (Tx± and Rx±) are protected against intrabuilding lightning transients. The LC03 TVS diode array diverts the majority of energy away from the transformer, but any common mode energy that does get coupled across the transformer interwinding capacitance is diverted to GND by the SP3051 TVS diode. This component can be connected to ground on the PHY side of the transformer because the IEEE 802.3 isolation requirements are met by the transformer itself.

Some industrial Ethernet circuit protection applications pose even greater challenges, such as in facilities with multiple buildings with equipment and cabling outside. Figure 2 shows a circuit protection scheme optimized for applications involving severe outdoor exposure in environments with frequent electrical storms.

Power over Ethernet

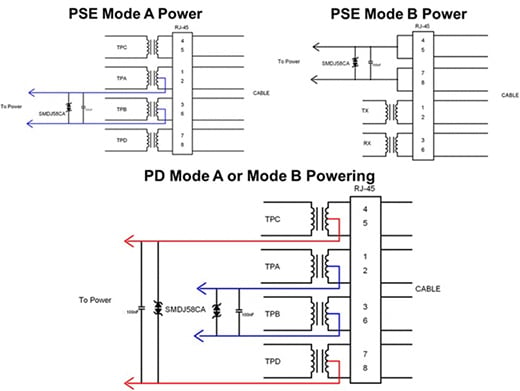

Power over Ethernet describes any of several standardized or ad hoc systems that pass electrical power along with data on Ethernet cabling. This allows a single cable to provide both a data connection and electrical power to a variety of devices, like IP security cameras. Unlike the USB bus, which also powers devices over the data cables, PoE allows extended cable lengths. Power may be carried on the same conductors as the data or on dedicated conductors in the same cable. In a PoE scheme, the device that receives the power is called the client device or powered device (PD), and the device supplying the power is the power sourcing equipment (PSE). “Mode A” power is supplied over the “active” data pair found in 10BaseT or 100BaseTX interfaces. “Mode B” power is applied over the unused pair for 10BaseT and 100BaseT interfaces. For 1000BaseT and 10 GbE applications, all wire pairs are used for data transfer, so there are no “spare pairs.” Figure 3 illustrates circuit protection schemes for PoE-powered device and power supply equipment.

Figure 3. A properly rated transformer and power supply provide the required isolation for IEEE 802.3 compliance. For the PSE, TVS diodes are used on the specific pairs that will provide the power. Shown here are 1,500 W versions for high-exposure cable and equipment installations. For short cables or installations with low lightning exposure, lower-power 600 W or 400 W components can be used. For the protection of the PD, both pairs need to be protected, as it will not be known ahead of time which pairs will provide power. TVS diodes should be selected based on the expected surge exposure level.

Figure 3. A properly rated transformer and power supply provide the required isolation for IEEE 802.3 compliance. For the PSE, TVS diodes are used on the specific pairs that will provide the power. Shown here are 1,500 W versions for high-exposure cable and equipment installations. For short cables or installations with low lightning exposure, lower-power 600 W or 400 W components can be used. For the protection of the PD, both pairs need to be protected, as it will not be known ahead of time which pairs will provide power. TVS diodes should be selected based on the expected surge exposure level.

CAN bus

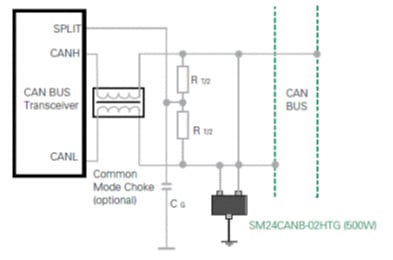

Industrial Ethernet and PoE are far from the only communication buses relied upon for factory automation system coordination. The controller area network (CAN) bus standard allows microcontrollers and devices to communicate with each other in applications without a host computer. Although not nearly as fast as Ethernet, CAN bus is highly robust and capable of communicating data reliably over substantially longer distances than Ethernet. That makes it a good choice for applications that require communicating instructions or returning data from separate pieces of equipment located some distance from each other. Figure 4 shows a typical CAN bus application example.

Figure 4. The TVS diode array is designed to protect CAN bus lines from damage due to ESD, EFT, and surge transients. It is suited for longer cable runs or cables that must be located close to power cables.

Figure 4. The TVS diode array is designed to protect CAN bus lines from damage due to ESD, EFT, and surge transients. It is suited for longer cable runs or cables that must be located close to power cables.

RS-485 (Profibus, fieldbus)

Much like CAN bus, RS-485 is highly robust and lets industrial users transmit data without degradation over longer distances, but it is somewhat faster than CAN bus. In industrial settings, it is often used to control lighting, security cameras, and fire detection systems. Figure 5 illustrates one type of circuit protection for RS-485 ports subject to ESD or low-level transients due to lightning-induced surges. Figure 6 represents a higher level of protection.

Figure 7. Low-profile, small-footprint protection thyristors protect high-density broadband equipment from damaging overvoltage transients.

Figure 7. Low-profile, small-footprint protection thyristors protect high-density broadband equipment from damaging overvoltage transients.

Communications using industrial networking is the backbone of automation and will grow in importance with future factories. Circuit protection technology properly applied is important to maintain conductivity and protect equipment.

About the Author

Jim Colby is senior business development manager for the electronics business unit of Littelfuse, Inc. His responsibilities include identifying and developing strategic growth markets and introducing new products into those markets. He received his BSEE from Southern Illinois University (Carbondale) and MBA from Keller Graduate School of Management (Schaumburg). He has been with Littelfuse for more than 17 years and in the electronics industry for more than 25 years.

A version of this article also was published at InTech magazine.