There is a growing need to optimize automation in industries to increase productivity, eliminate errors inherent to people-intensive processes, and create safer workplaces. This requires robust data in the right hands, at the right time, to make sound operational decisions.

Field device tool (FDT) technology is the key to integrating any device, system, or network in today’s complex automation architecture. The ongoing advancement of this technology is leveraging major developments like the Industrial Internet of Things (IIoT) and Industry 4.0, so end users can realize the potential of decentralization, interoperability, integration, as well as a unified view of all data and functions across process, factory, and hybrid control applications.

Operational demands

Modern process plants and factories have critical needs: integrating operations from beginning to end, bridging islands of automation, and distributing information throughout the enterprise. Even as industrial sites integrate their applications, they must comply with regulatory standards and meet stringent business requirements, which include tracking data and controlling the production environment to ensure product quality, consistency, and safety.

With an aging workforce ready to retire, millennials seeking access to new technology, reductions in budget and manpower resources, and the need to achieve operational excellence, it is important to employ all available information. Smart measurement and control devices are typically an underutilized resource that can dramatically help a facility’s decision-making process. Despite significant investments in intelligent devices, end users may not be maximizing the value of the information contained within those installed devices.

Diverse and complex control assets make integration complicated. Most industrial firms deploy different process fieldbuses and manufacturing networks in the same facility. This fact, combined with the challenging nature of today’s industrial environment, makes it difficult to achieve the benefits of operational and enterprise integration.

Traditionally, process and factory applications have worked separately, with little or no information sharing. This approach disregards the potential of smart data from installed intelligent assets. With new requirements for tracing a product all the way through the production process, control systems must share data and turn information into usable documentation.

Increasingly, industrial organizations require modern plants that can use advanced capabilities like the IIoT, Industry 4.0, system modularity, comprehensive interoperability, expanded worker mobility, and increased data security.

Technology ahead of its time

From the beginning, the FDT Group, an independent, not-for-profit association of international companies active in process and factory automation, developed its technology as an open, standardized solution. It had a single engineering environment, with a single interface, to integrate any device asset and network with access to performance-driven data—sensor to enterprise.

In many ways, the FDT, device type manager (DTM) solution was ahead of its time. Industrial facilities currently employing FDT-enabled systems are already benefitting from open access to the IIoT.

Recent FDT developments allow faster execution for mega-installations incorporating thousands of I/O devices. The technology supports an IIoT-connected enterprise, creating a single system infrastructure that standardizes the connection of disparate automation assets. Remote access to connected machines, production units, and devices is the impetus for performance improvements.

The FDT Group has also collaborated with the OPC Foundation to develop an industrial device information model, which supports greater interoperability, collaboration, and information sharing. This solution enhances the configuration of networks and devices, and gives the enterprise access to data without the complexity of protocol-specific handling. FDT’s method of communicating device and machine data using an industrial device information model is an effective combination of local control and monitoring with global overview and aggregation. It helps put “big data” in context and supports better and faster decision making.

In addition, FDT solutions can be implemented in a way that avoids possible cybersecurity threat vectors, providing unparalleled protection when integrated in control system vendor applications and hosted within a secure information technology (IT) platform. All applications created in compliance with the current FDT2 specifications are digitally signed for tamper-proof data delivery and nonrepudiation. And there is granular DTM security with enhanced user rights added to the security settings.

Although FDT is recognized as a communication catalyst providing interoperability between disparate devices on different networks, another often overlooked function is its ability to deliver diagnostic information for integrated assets, including networks and connected devices in the field. The technology’s support for smart device information monitoring and predictive diagnostics optimizes the life-cycle cost of plants while enhancing maintenance activities, increasing the safety of personnel and assets, reducing trips to the field, and improving product quality. Operations are also helped, because many FDT applications comply with the NE107 guidelines that define alert and notification symbols for problem recognition and resolution.

Industrial facilities employing FDT-enabled systems benefit from the robust capabilities of the IIoT.

Industrial facilities employing FDT-enabled systems benefit from the robust capabilities of the IIoT.

Meeting the needs of modern end users

The industrial sector needs to move information seamlessly from process to packaging, and from shop-level control systems to top-level business systems. Automation end users are seeking the latest technology advancements delivered out of the box, enabling modernized asset integration and access to performance data to visualize crucial operational problems.

FDT is an open-source standard that provides open access to device intelligence for all networks in the process and factory automation sectors. It creates a common communication method between devices and control or monitoring systems that are used to configure, operate, maintain, and diagnose intelligent assets. FDT is not a communication protocol, but rather a standardized asset integration and data delivery technology, allowing the connection to the IIoT and information flow from sensor to enterprise. FDT is recognized as an international (IEC 62453), ISA (ISA-103), and China (GB/T 29618) standard.

FDT technology consists of two main components: the frame application (an embedded component of the control system suite or a standalone application) and the device type manager (a device-specific application that launches within the frame). The DTM is a device driver that gives manufacturers control of the attributes displayed for the device. It includes diagrams and methodologies for configuring FDT-compliant devices. The frame application, on the other hand, renders a graphical user interface to DTMs and other device drivers, such as device descriptions, electronic device descriptions, and field device integration device packages. It is the unifying tool embedded in host applications, like asset management tools, programmable logic controllers (PLCs), or distributed control systems (DCSs).

Figure 1. A single FDT frame application, embedded in any host system, supports multiple networks and field communication protocols.

Figure 1. A single FDT frame application, embedded in any host system, supports multiple networks and field communication protocols.

The FDT standard is not new to the industry; it is easy to forget about embedded technologies that are not tangible. Most major system manufacturers currently integrate the FDT frame application interface in their offerings, and more than 8,000 devices are supported by FDT-certified DTMs—making it the most widely adopted standard for integrating devices in industrial control systems.

FDT/DTM solutions are effective for the new generation of smart operations, improving configuration, calibration, and diagnostics in the process industries, and optimizing network interfacing and device configuration in factory automation. The technology delivers valuable device and process information for cost-saving and operational improvements.

Interoperability is one of the prime motivators for adopting FDT technology. It is associated with the standardized integration of devices, systems, networks, and applications to reduce the time and cost of implementation. FDT supports heterogeneous control architectures, allowing best-in-class network and asset integration, as well as the cascade of information from sensor to the enterprise. The technology also frees end users from the constraints of a specific platform or communications method when configuring and monitoring devices. They can choose the best product for their installation and know that it is easily integrated into their system.

A single FDT frame application, embedded in any host system, supports multiple networks and field communication protocols, including HART, Profibus, Foundation Fieldbus, Modbus, CIP networks, Interbus, AS-Interface, Profinet, IO-Link, CC-Link, and ISA-100 wireless. The FDT open architecture allows end users to add networks to meet changing industry demands (figure 1).

Deploying FDT/DTM

Automation plays a critical role across the industrial landscape and involves a host of diverse tasks—both in different industries and in different areas of the same plant or factory. It demands the highest levels of integration and interoperability amongst measurement and control assets.

Process operations require advanced control, monitoring, and simulation. Emphasis is on continuous or batch mixing, reaction, and separation of materials to produce other materials of higher value. A DCS is most commonly used in process plants.

Discrete manufacturing involves the assembly of component parts to construct products that can be measured in units. These operations may use a DCS and PLCs to operate and control the motors, conveyors, robots, inspection systems, and similar devices that work together to complete the manufacturing process.

Applications having elements of discrete, batch, and continuous process control are often called hybrid. They typically require a process control system that can deliver both PLC and DCS capabilities.

Experience has shown that FDT/DTM bridges the chasm between different communication protocols used across facilities and industries and, as such, is helpful for the array of process, factory, and hybrid automation tasks. The traditional boundaries between areas of control do not exist for FDT technology, making it easier for engineers and production managers to set up seamless asset management.

FDT is particularly advantageous for hybrid automation applications in fields like food and beverage, fine chemicals, and pharmaceuticals, where many different technologies are used throughout a single facility and the enterprise. This includes process control networks running at an appropriate speed for the production side of the operation, and factory automation networks running at higher speeds for packaging and bottling. The challenge is to develop new strategies for maintaining cost-effective, sustainable production capacity. Any such strategy needs to take into account the efficient integration of the network infrastructure.

FDT technology harmonizes disparate plant networks and optimizes the strengths and capabilities of both process and factory automation for end users. The standard was specifically developed to provide an open, standard interface for integrating field devices with automation and asset management systems. Suitable for the growing array of hybrid applications, FDT has multi-network support and is independent of the communication protocol and software environment of both the device and host system—allowing any device to be accessed, from any host, using any protocol to support smart operations.

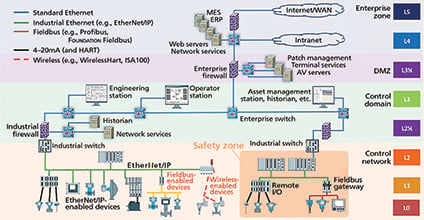

A key feature of FDT is “nesting,” which is the ability to seamlessly communicate through different types of networks to an end device. For example, this might start from an Ethernet network hosting a PLC or DCS, passing through several network layers to configure or communicate with a smart device. The FDT standard is written such that the end user has no awareness that routing through different networks is taking place. It is as if they are directly connecting to the device and can access all of its intelligent features.

Figure 2. A key feature of FDT is “nesting,” the ability to communicate through different types of networks to an end device.

Figure 2. A key feature of FDT is “nesting,” the ability to communicate through different types of networks to an end device.

Most importantly, FDT allows industrial organizations the freedom to choose best-in-class devices from any supplier without worrying about incompatibility. Because FDT breaks down proprietary barriers in control systems, it opens those systems to smart applications that can use all of the advanced features of the intelligent devices.

Timeless multiplatform integration

With FDT technology, industrial firms have already unlocked the power of the IIoT for crucial automation applications. They also gain the freedom to mix and match communication protocols, control system platforms, and solution suppliers, simplifying device integration for a modernized approach across diverse plant and factory environments. FDT can balance these needs, especially with the increased number of hybrid installations that combine elements of both forms of automation.

A version of this article also was published at InTech magazine.