This post was written by Walt Boyes, a principal at Spitzer and Boyes LLC, a technology consulting firm.

Picking a flowmeter takes both knowledge of the types of meters available and the kind of empirically derived knowledge that comes from experience. If you are like most people, you first think about the types of meters, their features, and their hardware and software. You might start to build the meter from the application requirements. You might list all the types of flowmeters and then pick one. The first cuts are obvious: liquid, solid, air, gases. Each cut separates out huge numbers of flowmeter types. Let's say your flow is liquid.

We are going to review the types of flow devices, look at selecting a flow device, and examine the real-world basics of flowmeter installation. Then, I hope you've brought your favorite flowmeter problem, because the doctor is IN.

There are lots of flow devices, for both liquids and gases, and for closed and open channels. We'll look at some of the most common devices, and focus on some simple ways to select and use them. Note that there are at least 10 different types, and they don't all work on all applications.

Positive displacement meters are used for both liquids and gases and are nearly always highly accurate. They come in a variety of types, such as oval gear, reciprocating piston, nutating disc, and rotary piston. They all work by emulating a bucket. One bucket in, one bucket out.

Differential pressure-based flow measurement is still the widest used technique throughout the process industries. Why? It is simple, inexpensive, and is accomplished by pressure transmitters, which the plant usually has for other measurements (pressure and level) anyway.

Turbines, paddlewheels, impellers, propellers . . . there are a wide variety of types and styles of volumetric mechanical meters, but they all work by converting the speed of a rotor to a volumetric flow value. They can be highly accurate (1 percent of reading) or only approximate (5 percent of span). They can be spool-piece style, bar-stock style, or insertion devices. They range from inexpensive to medium priced to fairly expensive models with high precision and special materials.

Because they measure the average velocity in the fluid directly, spool-piece magmeters can accurately measure flow. Other flow technologies that can rival a magmeter for installed accuracy include correlation-type ultrasonic flowmeters with calibrated spool pieces, and of course, Coriolis mass flowmeters. Note, however, that a point-velocity insertion magmeter is only about as accurate as a paddle wheel meter, because it only measures flow in a small cross-sectional area of the pipe.

Ultrasonic flowmeters are the most misapplied flowmeters around. When they were first introduced, they were supposed to replace all other types. But what happened is that they, too, found their niche. The "Prince Charming" of flowmeters has not yet come. Both transit time and Doppler ultrasonic flowmeters are now available.

Thermal dispersion is also used for highly accurate flowmeters in low-flow applications and can even be used for mass flow of gases. Considerable care, though, needs to be taken for applications like these. Beware of abrupt changes in fluid temperature.

Vortex shedding meters and other fluidic types have no moving parts and use the fluid itself the way a turbine uses its rotor. A traditional vortex shedding meter uses a bluff body (often called a shedder bar) to produce the repeatable oscillation. A swirl meter uses a stationary "rotor-like" device to twist the flow and a restriction to contain and make the oscillation repeat. They can be installed with little or no upstream straight run. Coanda-effect flowmeters use hydraulic feedback to force the fluid to oscillate in proportion to its velocity.

If I were told that I could pick only two types of flowmeters to use, forever, and that I would be judged based solely on the accuracy of the measurement, I would surely pick a Coriolis mass flowmeter as one of the two. A spool-piece style magmeter would probably be the other one.

In an open channel application, the "flowmeter" is the flow restriction itself: the flume or weir. The instrument is only the level sensor that automates the meter reading. You can use a yardstick and be quite accurate.

How do you select a flowmeter?

So far, we're clear that the previously listed first cuts are obvious. What is the next cut? The one I use is price. Most people use other cuts, but it all comes down to this. Can I spend less than $1000 USD or can I spend more? Why price? Price separates the most flowmeters of any possible cut I could make. Why the dollars figure? The figure of $1000 seems to be a clear dividing line between "inexpensive" and "expensive" flow elements.

You can make other cuts, too. Some of them might make you go back and reconsider the price cuts. For example, it is hard to find a 4-inch (100 mm) flowmeter with 1 percent of indicated rate accuracy for less than $1000. Therefore, if you need very high accuracy, you might be constrained to spend more than $1000 for the meter.

Look at the application. Does it require high accuracy, or, more likely, is it an application that requires good repeatability? Repeatability is usually cheaper than accuracy. If all you need is a good repeatable signal, say, to control a valve or feed a chemical, you will be paying more than necessary for a flowmeter if you buy a highly accurate one. Accuracy is important in precision batching and custody transfer. That is one of the reasons I use price as a major cut. In the end, we are back to the rule of two out of three: accuracy, repeatability, or economy-pick any two.

High temperature or high pressure might also make you reconsider the price cut. Wide flow rangeability may require another look, too. If you need a 20:1 turndown (i.e., the range a specific flowmeter can measure with acceptable accuracy), you can get several relatively inexpensive meters for most applications. If you need a 100:1 or 300:1 turndown, however, your available choices diminish rapidly. Chemical compatibility is another cut that might make your flowmeter choice more expensive. There are few meters available in larger than 1-inch sizes that are highly corrosion resistant, and most are expensive. Abrasion resistance is another consideration.

Of course, you MUST install the flowmeter correctly for it to operate correctly.

At the end of this process, you may find yourself with one or possibly two flowmeter types that survived your cuts. The last thing you should consider is the useful life expectancy you want. Once you have selected based on life, you are again down to price. Pick the least expensive flowmeter if there is more than one left. This one should meet your requirements.

This is a simple process, and it usually results in selecting the right flowmeter. It is the one I use, and I recommend it, because it will provide you with something no other selection process will. It will not over engineer the meter. You will not buy any more flowmeter than you need.

There are, however, people who use, as much as possible, the same flow meter for every application. I call this "design by shoehorn." I know an engineer in a pharmaceutical plant who tries to use Coriolis mass flowmeters for every application, even the measurement of process water. They work, but it is a little overkill. I know a systems integrator who tries to use inexpensive paddlewheel flow sensors for every application, even high temperature and high viscosity applications. The amazing thing is that often they work too, but this might be referred to as "underkill." Flow measurement is both art and science. There is substantial knowledge that is simply learned-empirically derived behavior. It is experience. Here is some of mine.

Many flowmeter manufacturers tell you that you need at least 10 pipe diameters upstream and five diameters downstream from a flowmeter of straight, unobstructed pipe. Most of these manufacturers have trouble with the question, "But I don't have 10 and five, I have three diameters upstream and two diameters downstream. What do I do now?" There are two answers to the question. The "straight" and "company-approved" answer is, "Change your piping, or your flowmeter will not be accurate, linear, or repeatable."

Of course, if changing the plumbing was an option, the poor victim wouldn't have called now would he? Yes, if you can change the plumbing, you should always do that first. Too many times, we try to select a flowmeter to cure a plumbing issue, and not reverse the process.

The empirical answer is, "Divide your straight run in thirds, and locate the centerline of the sensor at the point that is two-thirds of the distance from the start of the straight-run section. If you are using an insertion, or point-velocity sensor, make sure you put the sensor at the outside edge of the pipe where the velocity is highest." Now why does this work? Well, when it works, it is because it minimizes all the "design sins" you are committing. Putting the flow sensor at the two-thirds distance point gives you as much straight run as you can get without getting involved in problems from the downstream flow obstruction. For point-velocity sensors, putting the sensor into the flow stream at the high side of the disturbed velocity profile makes them more repeatable, although they will usually read high.

Installing a flow sensor into a vertical line with flow going up usually makes it work better even in disturbed flow profiles, too, because gravity can help develop the velocity profile in some applications. A vertical riser installation usually helps combat entrained air or gases in a liquid stream, too.

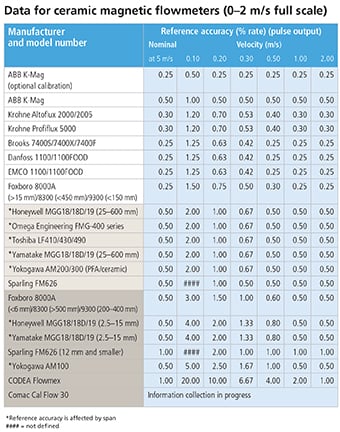

In 2013, Spitzer and Boyes, LLC did a study of the world's magnetic flowmeters. We found that flowmeters, even magmeters, are not commodity products. We divided magnetic flowmeter models into groups and compared their performance and reference accuracy against all the other models in the same group. The groups were: ceramic lined, electrodeless, low flow (smaller than 12 mm/1 inch), medium flow (between 12 mm/1 inch and 300-450 mm/12-18 inch), high flow (larger than 300-450 mm/12-18 inch), high noise, low conductivity, partially full, sanitary, fast response, and two wire. The chart shows some of the ceramic-lined meters compared against each other. Note the very large accuracy variations, especially at low flow rates.

This chart above clearly shows the differences between models, even between models from the same manufacturer! We found that the best-selling meters are not necessarily the most accurate.

About the Author

Walt Boyes has more than 25 years of experience in sales, sales management, marketing, and product development in the automation industry, including executive committee experience and board of directors service in both for-profit and not-for-profit companies. He was the long-time editor-in-chief of Control magazine and currently is a principal at Spitzer and Boyes LLC, a technology consulting firm devoted to assisting companies to better market their products in manufacturing and automation. Walt has published professionally in the technology and science fiction fields, and is a member of SFWA, the Science Fiction and Fantasy Writers of America.

Walt Boyes has more than 25 years of experience in sales, sales management, marketing, and product development in the automation industry, including executive committee experience and board of directors service in both for-profit and not-for-profit companies. He was the long-time editor-in-chief of Control magazine and currently is a principal at Spitzer and Boyes LLC, a technology consulting firm devoted to assisting companies to better market their products in manufacturing and automation. Walt has published professionally in the technology and science fiction fields, and is a member of SFWA, the Science Fiction and Fantasy Writers of America.

A version of this article also was published at InTech magazine.