This post was written by Amit Ajmeri, is a control system specialist with Chevron Phillips Chemical Company.

For profitable operations in today’s power and process plants, it is vital to improve overall efficiency and lower costs. To accomplish these goals, operations and maintenance personnel need to respond quickly to potential problems. Operations and maintenance teams are now asked to do more than simply identify problems and fix equipment breakdowns – they are now expected to work together to increase efficiency, minimize downtime, and extend the life of the plant’s equipment. The integration of maintenance data and associated methodologies into an asset management system can create a successful foundation for operations and maintenance teams to meet these challenges.

The latest instruments, analyzers, and valves provide not only important device-related data, but also information that can be used to ascertain the overall status of equipment and the entire facility. Current digital bus technologies, such as HART or the different varieties of fieldbus, make the procedures for detecting, documenting, and recording device alerts and other problems less costly and time consuming.

Organizing this data and documenting the actions taken to resolve problems is an important part of a plant’s overall maintenance strategy. By implementing a proper methodology, maintenance tasks become easier to assign and schedule. Equally important is the audit trail proving that maintenance tasks were executed properly. Documenting and tracking instrumentation maintenance data also produces valuable long-term records, so operations and maintenance personnel can better respond to specific issues.

This article will focus on instruments, analyzers, and valves, but it is important to note that many of the same maintenance procedures can easily apply to electrical equipment. This makes sense from an organizational point of view. Most process plants’ maintenance functions are organized around the instrument and electrical disciplines or a closely aligned group.

Asset management improvements

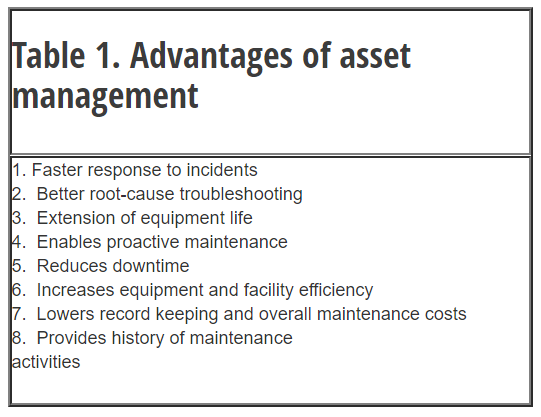

Most process plants use an asset management system that encompasses all large mechanical equipment, such as furnaces, tanks, turbines, and vessels. Twenty years ago, the asset management information pertaining to such equipment would probably be limited to the original documentation, with maybe a few modifications found in maintenance documents. The vast majority of this maintenance information was not in a central repository; maintenance-related documents were instead stored in different locations in various formats. When questions arose about the status of a particular asset, it was difficult to find relevant documents and historical maintenance records. It became clear to many plants that a better system for managing assets was needed. The asset management system had to encompass the entire life cycle of the mechanical equipment, along with incorporating real-time diagnostics. The system also had to be easy to use, and it needed to provide information to relevant parties in a variety of formats. With the right asset management system, operations and maintenance personnel can work together to proactively extend equipment life and prevent breakdowns by closely monitoring device diagnostics. Proactive maintenance translates into faster correction of abnormalities, and can extend equipment life while increasing the plant's overall efficiency and uptime. See table 1 for a summary of advantages provided by a correctly specified, installed, and maintained asset management system.

Proper planning essential

Selection, installation, and implementation of an asset management system must begin with a clear plan. The plan should underscore the mission and goals of asset management, and detail required ongoing activities. Showing workers how an asset management system can make their jobs easier and make their plant run more efficiently is the first planning step, as this will create buy-in and make subsequent steps easier to implement.

Explaining the connection between better maintenance records stored in an asset management system and lower overall maintenance costs will help operations teams understand the importance of good record keeping and will facilitate their participation. Operations staff should be trained to be the first responders, because a good asset management system will supply operators with critical information about potential problems on an ongoing basis. Maintenance staff should be shown how the right asset management system can help them go beyond the old methods of fix and repair.

They should be encouraged to adopt a maintenance philosophy that captures the most relevant operations data, and compares this data with past maintenance records. The right asset management system can help maintenance personnel create lists of potential devices that are prone or susceptible to failures. To implement this type of maintenance methodology, maintenance records cannot be separate from the operations' records, as all relevant information must be stored in a central repository-namely the asset management system. Record keeping must be a comprehensive process that makes it easy to cross reference records.

Employees must be confident that historical records, as well as the last maintenance action on specific devices, are organized for easy retrieval. In this early stage, great emphasis should be placed on embracing this methodology as a means to interpret the diagnostics provided by each and every instrument, analyzer, or valve.

Collecting data for easy access

Asset management system training begins by demonstrating how having readily available documentation simplifies the information retrieval for a specific device. By creating a single location for all pertinent data, organizations save many labor hours and can address problems more rapidly.

Creating a single data location starts by collecting all applicable data and entering this data into the asset management system. Most vendors provide electronic documents for each device, such as operating manuals and specification sheets, and those documents should be electronically attached to the asset management system to enable easy access. Additional information, such as equipment location and photos, as well as any specific information about the environment where the piece of equipment is located, should also be entered. Another useful device document is the piping and instrumentation diagram, along with the date of purchase and the commissioning date.

A specific naming convention for devices provides valuable information if there is a problem. For example, if a device is designated as environmental, the maintenance manager can easily query all devices associated with environmental monitoring. This is extremely helpful for a root-cause analysis. A similar convention can be established for other like groups of devices.

Documenting maintenance

After the initial stage of gathering and entering the documents associated with a device, the focus turns to maintaining a central point for maintenance records within the asset management system. The actions performed on each device and the name of the maintenance employee who performed those actions should be noted in the asset management records section. This maintenance documentation will be an integral part of the inspection schedule of individual devices.

Good record keeping can alert maintenance team members to specific devices that require more attention based on process conditions, such as vibration or corrosion. This helps determine if one type or brand of device requires excessive maintenance. Whether the process plant is a new unit ready to be commissioned or one with 15 years of continuous service, the maintenance plan should follow the required procedures as new devices are placed into service. The maintenance staff should follow stringent or regimented policies as to how those new devices will be installed and documented, as this consistency will streamline information retrieval.

Using asset management tools

One of the key advantages of an asset management implementation is the ability of the operations team to identify a potential device problem early and to alert the proper maintenance team. These types of coordinated efforts prevent small problems, such as a minor air leak on a valve or intermittent improper readings from a pH analyzer, from becoming more serious situations. Asset management diagnostic tools can provide clearly recognizable alerts for both operations and maintenance personnel that can help them determine the severity of a device problem.

When a call or alert occurs from a device, the first response should be to determine the severity of the problem. The next step is to determine who has recently maintained the device, and what other devices or processes may be affected by this specific issue. A correctly installed and maintained asset management system can facilitate these activities, speeding problem resolution and quickly returning the device back to its normal working state. Documenting actions taken to resolve problems will help technicians know the best procedure for correcting that type of problem in the future, and the asset management system is the recommended place to store this type of data.

Beyond troubleshooting

A good asset management system does more than help operations and maintenance staff troubleshoot problems; it can also help improve the overall operation of the plant. One of the tools provided by asset management systems is a pictorial view of all the devices installed corresponding to a particular process area. This diagnostic view will be the first place the skilled maintenance technician will look for a thorough overview of the overall plant asset status and operating efficiency.

A skilled maintenance person can view and analyze the operation of many instruments and valves from an asset management workstation. This view will provide a wide and varied list of devices and an easy-to-read indication of device problems. This overview information can then be used to make improvements. The asset management system, for example, can be used to retrieve valve diagnostic information, such as the detection of high- or low-friction conditions.

Friction data can be then displayed along with other corresponding information, such as valve supply pressure and temperature. With this new set of valuable related information, the maintenance technician can get a much better picture of the health of the valve, allowing proactive diagnosis of issues. Similar diagnostics from transmitters, such as the sensor temperature of pressure devices that indicates an abnormal temperature of the device, also offer important data that can be analyzed to predict problems before they occur.

These alerts and alarms are an early warning mechanism, enabling maintenance technicians to proactively solve problems and prevent more serious conditions. Furthermore, equipment can receive timely maintenance that extends its overall life. In today's modern plant, whether it is recently commissioned or an updated 10-year old facility, asset management plays a critical role in helping operations and maintenance personnel identify problems quickly. Asset management systems have easy navigation and document retrieval to help skilled technicians locate potential problems quickly and accurately, thus stopping small problems from becoming serious incidents.

About the Author

Amit Ajmeri is a control system specialist with Chevron Phillips Chemical Company, Prior to that position, he was a consultant for wireless and field network technology at Yokogawa Corporation of America and an engineer with Emerson Automation Solutions.

A version of this article also was published at InTech magazine.