This guest post, Part 1 of a two-part series, was authored by Narciso Santiago, CAP, a senior electrical engineer at Colas USA. To read the second post in this series, click this link.

Many times I have walked into different wastewater facilities control rooms and looked at the effluent residual trend, which to me looks like it is out of control. When I ask for the first time how the effluent residual control is performing, most likely I will get the same answer,

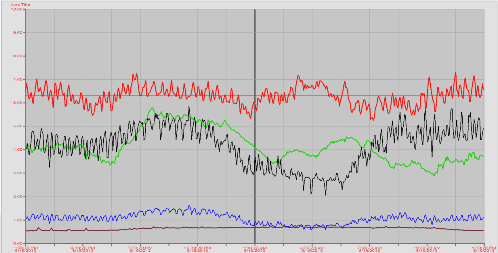

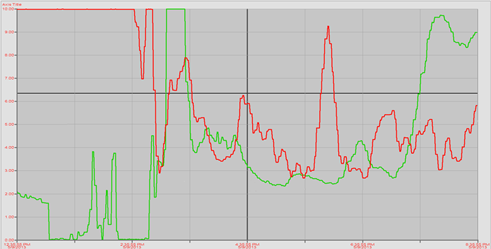

it’s doing OK. But in reality, there is a big difference between a trend depicting “in control” of effluent residual (Figure 1, below) and a trend depicting “no control” (Figure 2, below). Good control can simply be determined by the fact that the process variable will track the setpoint (in this case the residual measured). A lack of understanding of effluent residual control fundamental considerations results in higher operational and chemical costs.

A trend depicting a small deviation from setpoint demonstrates excellent process tuning. But in wastewater effluent facilities not having good control of residual results in chemical waste, and therefore, gaining effluent residual control is more important than having an excellent process tuning. The immediate result of gaining control of effluent residual is chemical savings.

Advance process control (APC) technologies can provide ultimate optimization for effluent residual control and should be utilized when process conditions demand process modeling and predicting capabilities such as processes with long and variable dead times. But since not all programmable logic controllers are APC capable, and gaining control of the effluent residual is more important than optimizing process tuning, APC technology is not a requirement to gain control of effluent residual.

Important factors for effective effluent residual control include correctly sized control elements; installation and maintenance practices; types of chlorine analyzers; and analyzer redundancy. But more important factors are fundamental considerations that include mixing at the point of injection and how it affects the flow stream; the measuring point location and why it matters; the process dead time and how it relates to choosing a more advanced control method or not; the processing algorithm which is an industry standard; and how a correction factor based on error between setpoint and process variable is implemented.

When there is no effective control of effluent residual, operational activities include time spent daily verifying the effluent residual will not go out of compliance, and taking multiple samples daily to determine the actual value of the effluent residual. Also, the operator is more likely to set the system to manual control, and set the chemical feed rate for enough chemical feed to guarantee the effluent residual will not go out of compliance.

The result of these activities will show up in the effluent residual trend depicting a process variable not tracking the setpoint. Worse, a residual trend indicating the residual measured at full scale does not represent the actual value of the residual measured; it’s higher. In contrast, when the effluent residual is under control, the time spent verifying if the residual is in compliance is now a matter of checking the influent and effluent residual trends for consistency; and a dosage adjustment is now based on the knowledge of actual process disturbances. In wastewater facilities with no effective control of effluent residual, addressing the important factors and implementing fundamental considerations mentioned above results in gaining control of effluent residual and reduction of operational time and chemical consumption.

Upgrading the programmable logic controller and software is most likely not required. Implementation and initial tuning can be completed in a few days. Additional tuning time may be required, but the overall implementation cost will most likely prove to be affordable with immediate cost savings in chemicals. In Part 2 of this series, I will offer a checklist to help you assess factors that must be considered to achieve automatic control of effluent residual.

About the Author

Narciso Santiago, CAP, is a senior electrical engineer at Colas USA. Prior to that position, he was project engineer at EMA, Inc. in Orlando, Fla., a company dedicated to the design, development, and implementation of control systems and automation for water and wastewater facilities. Prior to joining EMA, Narciso spent over 12 years at Gencor Industries, a manufacturer of asphalt plants, soil remediation plants, combustion systems and control systems. Narciso is an adjunct instructor for the School of Electronics Technology at ITT Technical Institute in Lake Mary, Fla. He earned a bachelor’s degree in electronics engineering technology from the University of Puerto Rico, and an associate of instrumentation engineering technology from the Technological Institute of Puerto Rico. Narciso has been a ISA Certified Automation Professional since April 2009.