With the advent of electronic governors, the control of steam turbines has become seamless and highly efficient. Thanks to the advance of central processing units (CPUs) integrated within the governing devices, the operation and control of machines has become significantly easier alongside machine diagnostics.

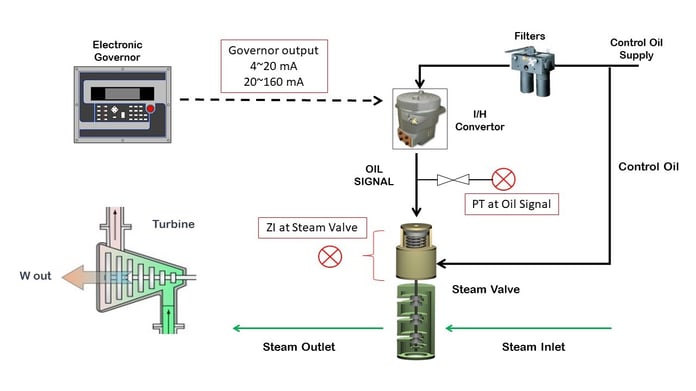

A noticeable growing trend in the manufacturing industry involves replacing the hydraulic flywheel type mechanical governors with the new electronic governing package. The complete electronic upgrade package is usually equipped with an electronic governor, current to hydraulic converter ‘I/H,’ over speed trip (OST) module, and solenoid trip block. This package is commonly included in every upgrade. Although this upgrade substantially enhances operations as well as maintenance and diagnostic abilities, there are some considerations that coupled with this upgrade will significantly enhance the true diagnostic ability of the electronic system.

To explain the effectiveness of these additional instruments, first allow us to examine the potential problem.

Potential Problem

When an electronic governing system is installed, it is usually not connected with the plant's distributed control system (DCS). The governing system and the DCS usually only exchange a few control parameters like Speed set-point, actual speed, and start/stop etc.

If an operational problem arises in the turbine or driven load, troubleshooting can become a challenge due to the limited information exchange between these two systems. As an instrument and process engineer, the approach of troubleshooting turbine governing problems starts by classifying them into two categories:

- Issues in plant operational parameters (e.g., steam inlet, extraction, driven load, other process conditions, etc.)

- Issues within the turbine governing system (e.g., governor, I/H, oil supply, steam valve, etc.).

This classification is necessary to identify the source of the problem. However, if critical parameters are not being exchanged between the DCS and governing system, this can lead to a state where it becomes nearly impossible to distinguish the problem cause from the effect.

Problem Solution and Critical Parameters

A few low-cost additions can help significantly, whether you are uprating a governing system of a turbine, or trying to more effectively identify the root cause of any governing problem in a facility that is already equipped with an electronic governing system.

- Governor Output Indication on DCS

One such addition is to replicate the governing output in the plant DCS by programming governor spare Analog Outputs and hardwiring them to DCS or using Modbus/digital connectivity of the governor with DCS. This parameter is crucial to observe governor behavior in response to process parameters and operator speed commands.

- Pressure Transmitter

Another addition is the installation of a pressure transmitter at the discharge of the I/H converter, which is then hooked up with DCS. By clubbing historical data of governor output and the pressure profile of I/H converter, any problems pertaining to the I/H converter can be easily identified.

- Position Indicator

The provision of an electronic position indicator on the steam intake valve is also critical. Although it can be challenging to mount the position indicator on the steam intake valve, it can be done with the advanced non-contact type technologies available in the market. By analyzing the position feedback with pressure signal, problems associated with the steam valve can be diagnosed easily.

The inclusion of the aforementioned instruments is often overlooked in the upgrade package due to several reasons including lack of information, engineering complexity associated with the interconnectivity of two systems, and the misconception that electronic systems are the ultimate solution.

It is essential to note that installing these additional instruments is not only useful for diagnosing problems but can also be critical in the prevention of faults. By continuously monitoring the governing system's performance and detecting any deviations, the system can be maintained and optimized, leading to extended service life and reduced downtime.

Conclusion

While electronic governing systems have undoubtedly revolutionized steam turbine control, their effectiveness can be significantly improved by incorporating critical parameters and instruments to ensure reliable and efficient operation. A holistic approach to turbine governing systems must consider the importance of process parameters and equipment parameters together for fault diagnosis and prevention.

Example Case

I have witnessed numerous cases where the instruments described above have assisted in resolving turbine-governing issues. However, one specific instance stands out above all others. At a chemical manufacturing plant, we encountered a 100 RPM dip in a high-speed multi-stage turbine compressor driven by a steam turbine. The dip occurred at a fixed schedule of 24 hours daily, yet despite a thorough analysis of plant operational parameters and governor diagnostics, we were unable to determine the root cause. Eventually, we decided to connect the I/H pressure indication with the DCS system. During the next dip, the I/H output pressure dipped out-of-sync with the governor output, leading us to identify the I/H converter as the root cause. We discovered that the I/H governor was programmed for a 1% movement after every 24 hours to remove any silt in the valve internals. Although this 1% was intended to have no effect on turbine speed, the aging I/H governor internals were compromised, resulting in a dip in turbine speed when the program was executed. This programming function came as a default feature of the I/H converter and was overlooked during the governing system installation.