Preface: Safe Operation Is the Process Industry’s Top Concern

Refineries and petrochemical plants handle various hazardous materials and processes. The 24/7 nature of their operations poses immense challenges with respect to safety, compliance, and reliability. While there is a continuous emphasis placed on competitiveness, product quality, and meeting societies’ requirements for a steady flow of supplies, every plant’s paramount focus is on operating in a safe and environmentally endurable manner.

Digitization in the Process Industry: A Definitive Way Forward

In the last five to 10 years, a wide variety of stakeholders have generated a lot of interest about Industry 4.0 characteristics such as automation, deploying robotics, IIoT, blockchain, cloud computing, and IT/OT integrations. Leading companies have deployed automated business processes with robust data management systems, preventive and predictive analytics, digital twins, and so on. Companies such as Shell, Exxon, BP, Reliance, and Aramco have deployed these types of technologies in an assorted and/or integrated manner for holistic benefits. The projects have spanned areas such as production enhancement, agile profit improvement opportunities (PIO) management, meeting the required product quality with minimum quality giveaways, and processing cheaper feedstocks, for example.

Many automation and/or digitization projects also have been implemented to improve process safety, workplace safety, environmental compliance, equipment and operational reliability, plant integrity, and so on. Almost every plant or company has tried to move ahead with some aspect of digitization in a careful manner, considering the costs and benefits.

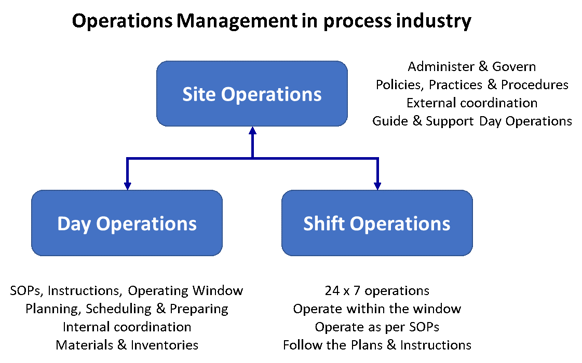

Operations Management

Operations management of a process plant can be divided into two verticals: shift operations and day operations. Typically, the shift operations work on a 24/7 schedule. The object of shift operations is to execute all activities in a safe and flawless manner. There are three aspects to this goal, namely:

- Operate the plant and equipment within the defined operating window all the time

- Conduct all operations as per defined procedures

- Operate the plant as per plans and instructions received from day operations

In a process plant, typically about 40% of the rotating equipment is on standby, with the balance in running mode. Depending on the state of the equipment, its “operating window” is defined and must be kept. Similarly, a plant under shutdown must be watched and kept at a defined shutdown state. It’s not uncommon to see, in a plant under shutdown, that columns have gone under over-pressure situations or tanks have overfilled, leading to undesirable events.

A quick review of past accidents in the process industry tells us that situations often arise due to operating without a set procedure—or, at times, using a wrong procedure.

The shift operations crew needs to be provided with proper plans and instructions in a written format to avoid miscommunication. Unloading a tanker in the wrong storage vessel or dispatching the wrong product to a customer, for example, are not uncommon when plans or instructions are not available.

The object of day operations is to have a midterm view of the operations and align this with business plans. The day operations collaborate with technical and engineering staff and ensure the right operating window is defined and made available to shift operations. They also ensure that all required procedures are available. One of the daily chores of day operations is to supply the production plans and operating instructions to the shift crew.

Day operations are also concerned with the required competencies of the asset-facing crew, and have an elaborate program to define and develop them.

Other than the shift and day operations, there is a third angle: site operations. The object of site operations is the proper administration and governance of all programs and activities of the whole site. Various staff and functions in the organization ensure the same is done so that the site’s or company’s overall goals are defined and achieved.

Diagram courtesy of the author.

Digitization of Operations Management

To help meet all the goals of shift, day, and site operations, several aspects of their management may be considered for digitization.

Digitize Operating Window

In a traditional operation, the operating window is kept as a document in Microsoft Excel, Word, or a .pdf document. Such a document is usually reviewed and revised at some interval ranging from three months to a year. But the plant is run with an operating window that is embedded into the DCS in the form of alarms, and shift operations are expected to operate within the window.

Since process plants run under several states, and considering that various pieces of equipment are at different states at any given time, it is beneficial to define an operating window for all equipment and processes against different states under a digital platform. This digital data set is deployed over an IT platform, and when effectively integrated with DCS in real time, there is an assurance that the shift operations are empowered to look at the defined operating window in real time and operate the plant accordingly.

Honeywell, Emerson, Yokogawa, and others have developed these types of IT applications that can hold the digital operating window and integrate with DCS. The Abnormal Situation Consortium, promoted by several companies like Shell, Exxon, Emerson, and Honeywell, have come out with analysis that about 40% equipment failures or degradations can be avoided if the equipment operates within the defined window all the time. The digital platform empowers shift operations to be continuously aware of the right operating window and control the equipment and process conditions in real time.

Digitize Procedures and Checklists

Shift operations are provided with standard operating procedures (SOP). Almost all activities that are typically performed in shift are documented in the form of SOPs. Quite often, some SOPs have checklists. These SOPs are usually available in Word or .pdf format. Such SOPs are usually well-managed over a powerful content management system on the IT platform. Shift operations are expected to take a printout and use it according to site practices. The checklists, once filled, are kept or scanned and uploaded into the system.

There is an opportunity to digitize the SOPs and checklists. Digitized SOPs and checklists can be customized for each piece of equipment so rigorously that it is possible to make certain that using the wrong checklist or procedure is avoided for any shift task.

Digitize Operating Plans and Instructions

Operating instructions are usually communicated by writing in a register which is available in the plant control room. Shift crew must read the same and sign off to acknowledge.

When the operating plans and instructions are digitized, it becomes easy to monitor how the shift crew followed the instructions and what difficulties were faced while executing the instructions or orders. It is possible to analyze various events and trends vis-à-vis shift instructions, and one can even “activate” instructions under certain conditions so that reliance on people is avoided in context-dependent situations.

Digitize Competency Framework

Asset-facing staff competency is honed depending on the number of opportunities in practicing various tasks. The shift tasks typically involve equipment condition monitoring, equipment changeovers, equipment isolations and handover, starting and stopping equipment, and so on. Asset-facing staff are also the first people on the ground to encounter emergency situations and respond with the proper actions.

In a traditional practice, competencies are defined and measured against the number of training sessions attended, the number of tests passed, the number of hours spent on training simulators, and so on. In a digitized competency management framework, however, it is possible to measure the number of opportunities a particular operator came across, such as filter bank back wash, molecular sieve bed regeneration, and equipment isolation and safe handover. The number of successful actions and faults in execution can be digitally tracked and used for improvement.

Digitize Site Operations

As mentioned previously, site operations is all about administration and governance. It involves defining and managing central standards, procedures, practices, and policies. It encompasses business coordination; planning and scheduling; inventory management; material management; contractor management; HR; regulatory compliance; customer, supplier, and community engagement; security; and many other areas of expertise.

Digitization provides opportunities for improving efficiencies in many aspects of site operations, especially in production planning and inventory control. Digitization can help with quality control and assurance; cost control; management of catalysts, chemicals, and other materials; contractor management; and so on.

To improve safety, various types of process safety information can be digitized, such as PFDs, P&IDs, and data sheets. End-to-end digitization—supported by robust data structures of various process safety management (PSM) processes—will provide near-term as well as long-term benefits to the organization.

Other Benefits of Digitization

Digitization of various operations management activities provide immense benefits. One of these worth highlighting here is the potential for developing models and performing analytics. Digitized data can be used for diagnostics, preventive and prescriptive analytics, predicting residual life of equipment, predicting run lengths of catalysts, statistical process control, and so on. In many cases, digitization done properly provides better insights into process capabilities and limits, which can be used for more effective planning.

Interested in reading more articles like this? Subscribe to ISA Interchange and receive weekly emails with links to our latest interviews, news, thought leadership, tips, and more from the automation industry.