The following technical discussion is part of an occasional series showcasing the ISA Mentor Program, authored by Greg McMillan, industry consultant, author of numerous process control books, 2010 ISA Life Achievement Award recipient and retired Senior Fellow from Solutia Inc. (now Eastman Chemical). Greg will be posting questions and responses from the ISA Mentor Program, with contributions from program participants.

In the ISA Mentor Program, I am providing guidance for extremely talented individuals from countries such as Argentina, Brazil, Malaysia, Mexico, Saudi Arabia, and the U.S. This question comes from Daniel Rodrigues.

Daniel Rodrigues is one of our newest protégés in the ISA Mentor Program. Daniel has been working in research & development for Norsk Hydro Brazil since 2016 specializing in:

- Development of a greener, safer, more accurate, and cheaper analytical method

- Cost reduction, efficiency enhancement opportunities identification

- Process modelling and advanced control logic development and assessment

- Research methodology development, execution, and planning

- Statistical analysis of process variables and test results

Daniel Rodrigues’ Question

What is your take on process control based on phenomenological models (using first-principle models to guide the predictive part of controllers)? I am aware of the exponential growth of complexity in these, but I’d also like to have an experienced opinion regarding the reward/effort of these.

Greg McMillan’s Answer

I prefer first principle models to gain a deeper understanding of cause and effects, process relationships, process gains, and the response to abnormal situations. Most of my control system improvements start with first principle models. The incorporation of the actual control system (digital twin) to form a virtual plant has made these models a more powerful tool. However, most first principle models use perfectly mixed volumes neglecting mixing delays and are missing transportation delays and automation system dynamics. For pH systems, including all of the non-ideal dynamics from piping and vessel design, control valves or variable speed pumps, and electrodes is particularly essential, I have consequently partitioned the total vessel volume into a series of plug flow and perfectly back mixed volumes to model the mixing dead times that originate from agitation pattern and the relative location of input and output streams. I add a transportation delay for reagent piping and dip tubes due to gravity flow or blending. For extremely low reagent flows (e.g., gph), I also add an equilibration time in dip tube after closure of a reagent valve associated with migration of the reagent into the process followed by migration of process fluid back up into the dip tube. I add a transportation delay to electrodes in piping. I use a variable dead time block and time constant blocks in series to show the effect of velocity, coating, age, buffering and direction of pH change on electrode response. I use a backlash-stiction and a variable dead time block to show the resolution and response time of control valves. The important goal is to get the total loop dead time and secondary lag right.

Join the ISA Mentor Program

The ISA Mentor Program enables young professionals to access the wisdom and expertise of seasoned ISA members, and offers veteran ISA professionals the chance to share their wisdom and make a difference in someone’s career. Click this link to learn more about how you can join the ISA Mentor Program.

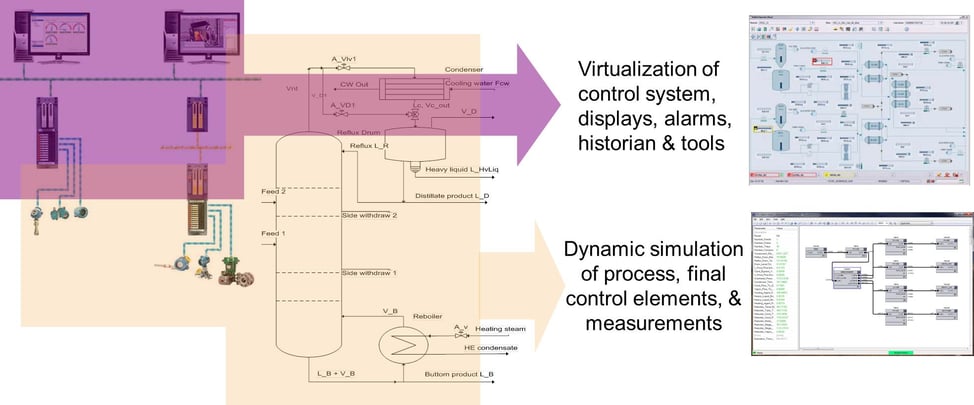

By having the much more complete model in a virtual plant, the true dynamic behavior of the system can be investigated and the best control system performance achieved by exploring, discovering, prototyping, testing, tuning, justifying, deploying, commissioning, maintaining and continuously improving, as described in the Control magazine feature article Virtual Plant Virtuosity.

Figure 1: Virtual Plant that includes Automation System Dynamics and Digital Twin Controller

Figure 1: Virtual Plant that includes Automation System Dynamics and Digital Twin Controller

Model predictive control is much better at ensuring you have the actual total dynamics including dead time, lags and lead times at a particular operating point. However, the models do not include the effect of backlash-stiction or actuator and positioner design on valve response time and consequentially on total loop dead time because by design the steps are made several times larger than the deadband and resolution or sensitivity limits of the control valve. Also, the models identified are for a particular operating point and normal operation. To cover different modes of operation and production rates, multiple models must be used requiring logic for a smooth transition or recently developed adaptive capabilities. I see an opportunity to use the results from the identification software used by MPC to provide a more accurate dead time, lag time and lead time by inserting these in blocks on the measurement of the process variable in first principle models. The identification software would be run for different operating points and operating conditions enabling the addition of supplemental dynamics in the first principle models. This addresses the fundamental deficiency of dead times, lag times and lead times being too small in first principle models.

Statistical models are great at identifying unsuspected relationships, disturbances and variability in the process and measurements. However, these are correlations and not necessarily cause and effect. Also, continuous processes require dynamic compensation of each process input so that it matches the dynamic response timewise of each process output being studied. This is often not stated in the literature and is a formidable task. Some methods propose using a dead time on the input but for large time constants, the dynamic response of the predicted output is in error during a transient. These models are more designed for steady state operation but this is often an ideal situation not realized due to disturbances originating from the control system due to interactions, resonance, tuning, and limit cycles from stiction as discussed in the Control Talk Blog The most disturbing disturbances are self-inflicted. Batch processes do not require dynamic compensation of inputs making data analytics much more useful in predicting batch end points.

I think there is a synergy to be gained by using MPC to find missing dynamics and statistical process control to help track down missing disturbances and relationships that are subsequently added to the first principle models. Recent advances in MPC capability (e.g., Aspen DMC3) to automatically identify changes in process gain, dead time and time constant including the ability to compute and update them online based on first principals has opened the door to increased benefits from the using MPC to improve first principle models and vice versa. Multivariable control and optimization where there are significant interactions and multiple controlled, manipulated and constraint variables are best handled by MPC. The exception is very fast systems where the PID controller is directly manipulating control valves or variable frequency drives for pressure control. Batch end point prediction might also be better implemented by data analytics. However, in all cases the first principle model should be accordingly improved and used to test the actual configuration and implementation of the MPC and analytics and to provide training of operators extended to all engineers and technicians supporting plant operation.

I would think for research and development, the ability to gain a deeper and wider understanding of different process relationships for different operating conditions would be extremely important. This knowledge can lead to process improvements and to better equipment and control system design. For pH and biological control systems, this capability is essential.

For a greater perspective on the capability of various modeling and control methodologies, see the ISA Mentor Program post with questions by protégé Danaca Jordan and answers by Hunter Vegas and I: What are the New Technologies and Approaches for Batch and Continuous Control?

Additional Mentor Program Resources

See the ISA book 101 Tips for a Successful Automation Career that grew out of this Mentor Program to gain concise and practical advice. See the InTech magazine feature article Enabling new automation engineers for candid comments from some of the original program participants. See the Control Talk column How to effectively get engineering knowledge with the ISA Mentor Program protégée Keneisha Williams on the challenges faced by young engineers today, and the column How to succeed at career and project migration with protégé Bill Thomas on how to make the most out of yourself and your project. Providing discussion and answers besides Greg McMillan and co-founder of the program Hunter Vegas (project engineering manager at Wunderlich-Malec) are resources Mark Darby (principal consultant at CMiD Solutions), Brian Hrankowsky (consultant engineer at a major pharmaceutical company), Michel Ruel (executive director, engineering practice at BBA Inc.), Leah Ruder (director of global project engineering at the Midwest Engineering Center of Emerson Automation Solutions), Nick Sands (ISA Fellow and Manufacturing Technology Fellow at DuPont), Bart Propst (process control leader for the Ascend Performance Materials Chocolate Bayou plant) and Daniel Warren (senior instrumentation/electrical specialist at D.M.W. Instrumentation Consulting Services, Ltd.).

About the Author

Gregory K. McMillan, CAP, is a retired Senior Fellow from Solutia/Monsanto where he worked in engineering technology on process control improvement. Greg was also an affiliate professor for Washington University in Saint Louis. Greg is an ISA Fellow and received the ISA Kermit Fischer Environmental Award for pH control in 1991, the Control magazine Engineer of the Year award for the process industry in 1994, was inducted into the Control magazine Process Automation Hall of Fame in 2001, was honored by InTech magazine in 2003 as one of the most influential innovators in automation, and received the ISA Life Achievement Award in 2010. Greg is the author of numerous books on process control, including Advances in Reactor Measurement and Control and Essentials of Modern Measurements and Final Elements in the Process Industry. Greg has been the monthly "Control Talk" columnist for Control magazine since 2002. Presently, Greg is a part time modeling and control consultant in Technology for Process Simulation for Emerson Automation Solutions specializing in the use of the virtual plant for exploring new opportunities. He spends most of his time writing, teaching and leading the ISA Mentor Program he founded in 2011.

Connect with Greg: