AutoQuiz is edited by Joel Don, ISA's social media community manager.

This automation industry quiz question comes from the ISA Certified Automation Professional (CAP) certification program. ISA CAP certification provides a non-biased, third-party, objective assessment and confirmation of an automation professional's skills. The CAP exam is focused on direction, definition, design, development/application, deployment, documentation, and support of systems, software, and equipment used in control systems, manufacturing information systems, systems integration, and operational consulting. Click this link for more information about the CAP program.

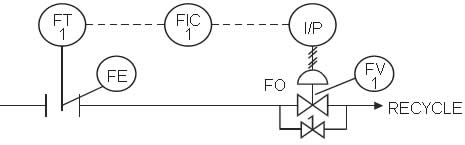

The liquid flow control loop in the post image is installed at a plant where it is suspected that the amount of recycle flow is somewhat more than what is being displayed by FT-1, a digital flow transmitter. The flow transmitter was recently re-calibrated and does not display any signs of damage. The installation appears to be in conformance with good instrument installation practices. Given this information, you determine that one potential cause of the apparent discrepancy in flow may be:

a) The control valve positioner is outputting a signal that is higher than requested by the flow controller.

b) The flow control valve bypass valve is fully closed when it should be open.

c) The orifice plate that has been eroded, thereby increasing the effective size of the orifice.

d) Square root extraction is enabled at the transmitter, but should not be for this flow measurement loop.

e) none of the above

The orifice plate that has been eroded, thereby increasing the effective size of the orifice. Liquid flow through an orifice plate can be represented by Q, volumetric flow rate,

Q = C x A √ [2∆P / ρ]

where C = meter coefficient (constant), A = orifice hole diameter, ∆P = pressure drop across the orifice plate, and ρ = fluid density. Erosion of the orifice opening will result in a larger effective orifice diameter than was originally provided with the orifice plate. From this equation, if the orifice diameter, A, is larger than it is assumed to be, the actual flow rate will be greater than anticipated for an equivalent pressure drop. The recent re-calibration of the flow transmitter would not have identified this problem. Periodic visual inspection of orifice plates is required to ensure the integrity of measurement with this type of sensor.

Answer A is not correct. For a fail open valve (air to close), a higher positioner output would have resulted in a lower recycle flow rate initially. However the feedback loop would have detected the lower flow and would have adjusted the final control element output accordingly.

Answer B is not correct. A control valve bypass is not meant to be opened except for maintenance purposes. If the valve had been opened, the increased flow would have been seen by FT-1 and the control valve output would have been adjusted accordingly.

Answer D is not correct. For a differential pressure flow element such as the orifice plate in this example, square-root extraction must be enabled. (Had this feature not been enabled, then a flow rate higher than the actual flow rate would have been registered by the flow transmitter).

The correct answer is C.

Reference: Measurement and Control Basics, Fifth Edition, by Hughes, Thomas.

About the Editor

Joel Don is the community manager for ISA and is an independent content marketing, social media and public relations consultant. Prior to his work in marketing and PR, Joel served as an editor for regional newspapers and national magazines throughout the U.S. He earned a master's degree from the Medill School at Northwestern University with a focus on science, engineering and biomedical marketing communications, and a bachelor of science degree from UC San Diego.