Every time I have a meeting with a customer, I am always surprised about all the ideas they have about how to automate this and that or how this part could be done better. The worst part though is that sometimes I have the difficult role of telling them that half of the things they want to do cannot be done. Even if the technology is evolving like crazy, there is still a huge gap between what you think can be done with robots and what can actually be done. This leads me to the subject of this blog post, what’s hard and what’s easy to automate.

As you look at your entire manufacturing process, there are probably hundreds of different steps that can be automated. Some are easier than others, some ask for more dexterity and some are really tough to accomplish. Since there are a broad range of possibilities, I‘ll try to keep this post simple by separating it into just a few different sections for the automation process.

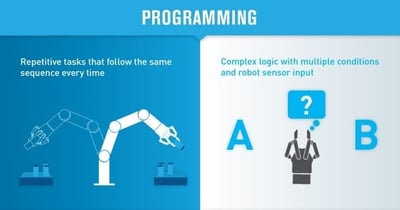

The bottom line is, that robots can still be pretty complex, BUT there are some applications that are easier than others. This is why we have split the image in our graphic into two sections with an easy and hard side. It is not that the hard side is impossible to do, it is just more complex and requires more effort.

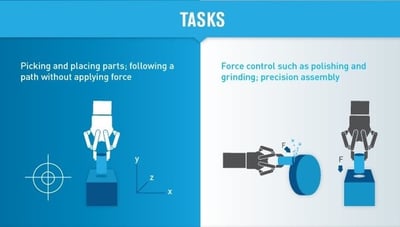

Tasks

The complexity of the automation process usually depends on the task itself. In fact, if the task is a simple pick and place, this is ideal for a robot since robots are really good at repeating the same position again and again. No repetitive stress injuries fo r the cobot.

r the cobot.

However, if the task requires vision or a sense of touch, the level of complexity rises quickly. If your application requires more “senses," then the integration will be more complex.

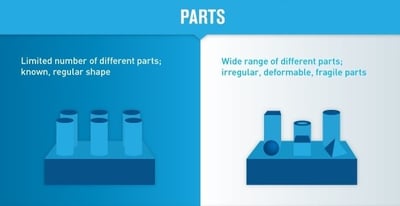

Parts

The choice of the part you will handle is critical in a robotic application. Regular part geometry such as squares, parallel flat sections, or cylinders are easy to grasp with a robot gripper.

If irregular or fragile parts have to be handle by the robot, this increases the complexity of the grasping process. Adaptive Grippers or custom made grippers might then have to be use  in order to grasp the part correctly.

in order to grasp the part correctly.

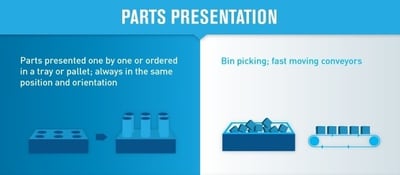

Part Presentation

You need to think about how to present the part to the robot. The best way to accomplish this is to structure the parts so that they make the same presentation to the robot before the robot grabs them. In fact, placing them in a line, a matrix, a grid or some other ordered method will make the robots job a lot easier.

If the parts are all mixed up and the robot has to identify each part or if the parts are running on a conveyor, for example, this increases the complexity of your cell. In this case, you will probably require a vision system that adds complexity to your automation project.

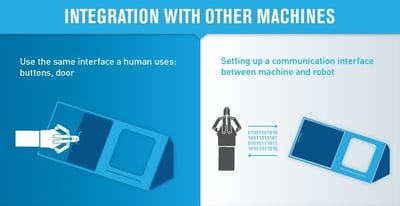

Integration With Other Machines

Integrating a robot with another machine is often the most complex part of the automation setup. In fact, since there are a lot of machines out there and there are almost as many robots, it is hard to find robots and machines that speak the same language. Most robots will have I/O entries that will make the life easier in terms of communication.

If your machines don’t speak the same language, you should keep in mind that there is still a way to set up communications, but again it will be more complex. If your application does not use an  external machine, then your automation project should be relatively simple, lucky you. If not, then you have a bit of work to do here, but it is still very doable. We do recommend the use of external service providers when the integration becomes more complex. This way you will not be wasting your time and you’ll get your automated cell up and running pretty fast.

external machine, then your automation project should be relatively simple, lucky you. If not, then you have a bit of work to do here, but it is still very doable. We do recommend the use of external service providers when the integration becomes more complex. This way you will not be wasting your time and you’ll get your automated cell up and running pretty fast.

Note that timers are really not a good way to integrate your robot with other machines. In fact, if you make your robot wait a certain amount of time while the other machine runs through its cycle, you’ll have a greater chance that your robot will fail over time because eventually the two machines will become out of sync.

Programming

Collaborative robots are easier to program since many use hand-guided programming methods. Classic industrial robots are generally harder to program since you often need to perform the programming offline. This means that you need to hire a full-time robot programmer or to ask an external service provider to set up each robot program you want to use.

Robots are good for redundant, boring things, they are not yet good at decision-making. This is why in your program you should reduce the level of logic required to the most basic sequence. Do not try to involve complex “if’’ statements or other conditional functions in your program if you don’t actually need it.

These are the five basic areas you need to look at when automating a process using a robot. As your automation project has the potential to save your company time and money, it is important to make sure you are making a wise hardware selection. Important in this decision is that all the sensors and tools can be fit together with very little effort. This will make your job a lot easier when you install and set up the robot. It can also mean that you can tweak or re-purpose the robot in house, which will be more efficient over the long run.

Once you have identified your process, and chose what your robotic cell will look like, I still recommend starting small. Build from your first experience. Try to choose an easy application that requires little adjustment and that is stable when done by a human worker. You will have fewer problems debugging it since you are more in control of the process. Adding a robot will then be simple. Notice that if you start with a complex task, you will not solve all your problems by simply putting a robot in the place of a human.

Finally, don’t be afraid to try different set ups with your robot. Even with a very a simple robotic cell, you can add simple devices that will make your application a lot easier. So I hope I encouraged another user to implement another great robotic cell? Did I?