In today’s digital age, new technologies like artificial intelligence (AI), machine learning (ML), augmented reality/virtual reality (AR/VR), blockchain, IoT, 3D printing, and automation have transformed the product lifecycle immensely and changed consumer behavior drastically, irrespective of any specific industry or sector.

In this article, we will talk about the fundamentals and challenges of AR and its varied industry applications, specifically in the manufacturing sector.

In general, augmented reality (AR) can be defined as one or more forms of immersive, sensory user experiences that integrate real-world environments and computer-generated information.

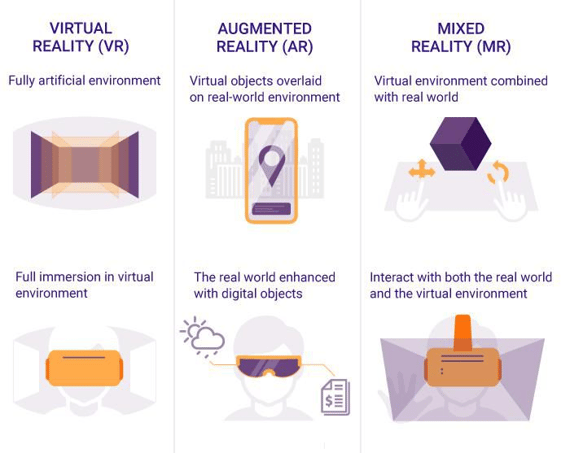

What Are the Different Types of Immersive User Experience Technologies?

Virtual reality (VR) takes users into a virtual, fully artificial world using headset wearable devices. It enables users to interact with a computer-simulated, 360-degree-view reality.

The most common applications of VR are in the gaming and entertainment industry, such as car/bike racing games and simulations, war zone games and simulations, sports, jungle safari games and simulations, and 5D/7D animated cinema.

Augmented reality (AR) gives an immersive user experience when computer-generated virtual objects are overlaid onto real world environments with the help of mobile phones, tablets, and smart glasses through the device camera.

The most common applications of AR are in retail, e-commerce, education, and the media and entertainment industry, offering exceptional user experiences for buying products online, interactive learning, and increased viewership, respectively.

Mixed reality (MR) is an advanced version of augmented reality, blending real and virtual worlds and allowing them to interact with each other in real time.

The most common applications of MR are in medical science for assisting in advanced surgery, forensics, and postmortems.

Image source: Forbes

What Types of Technology Are Used in Augmented Reality?

AR can be experienced via wearable smart glasses, or a mobile phone or tablet with a camera. The device may use AI, ML, Internet of Things (IoT) technology, data analytics, and computer-generated virtual objects to assist users in performing complex tasks and getting real-time insights for informed decision-making.

What Are Some Use Cases for AR in Smart Manufacturing?

The application of AR in conjunction with IoT and AI has enabled new possibilities in product development, manufacturing, machine maintenance, logistics, and customer support.

- Product development: With advancements in technology, environment regulations, and customer expectations, new product development is challenged to deliver shorter time-to-market at lower cost.

The use of AR in early product development helps designers iterate their designs virtually and more flexibly from idea to concept stage, without incurring rapid prototyping cost. - Manufacturing: From the first Industrial Revolution to Industry 4.0, the number of components in any product has grown a thousand-fold, making the assembly process more complex and tedious for workers to perform error-free tasks in the quickest way possible.

AR-guided interactive voiceover work instructions are used in complex assembly processes for mobile phones and aircraft, for example. The process can then get faster and error-free, without putting immense pressure on workers. - Machine maintenance: The need for products of the finest quality has led to the use of very sophisticated and complex machines in manufacturing setups, Of course, sudden machine breakdowns have always resulted in downtime and production loss.

AR can cut down on periodic machine maintenance and breakdown losses with real-time daily monitoring. It can also help predict potential failure trends by performing quick diagnostics, as well as faster repair and recovery. - Logistics: A reduction in warehousing operation cost has always been in sight, due to loss in delivery time and damages caused by improper cargo handling or loading.

AR can streamline cargo picking for loaders with assistive and interactive voiceover guided instructions to locate the right cargo and find where it must be placed in a vehicle. - Customer support: Usually, onsite OEM customer support needs multiple technician visits to run diagnostics, order spare parts, and replace or repair equipment. This makes it challenging for OEM to deliver better customer experience by the fastest resolution possible.

AR smart glasses can offer technical customer support in real time with personalized instructions in a remote working environment, and can help fix issues faster without the need for a physical visit.

Overcoming Challenges in AR Adoption

AR product development faces a lot of challenges in realizing its full potential. Adoption of AR can accelerate with the advancement of these technologies:

- 5G data connectivity: Low latency data transfer in real time

- Highly trained AI models: Based upon different applications, AI model should be highly trained to enable real-time interactive user experience

- High-quality virtual objects: A real-like virtual objects creation showing every possible detail

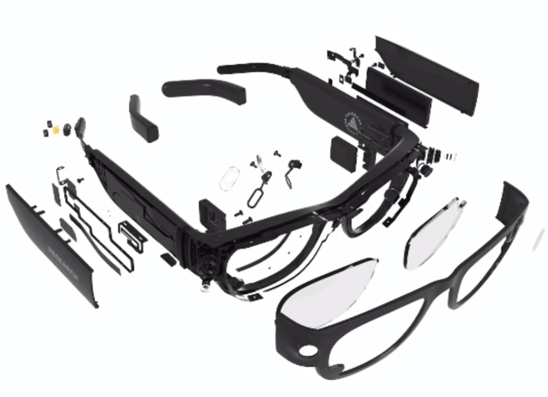

- Miniature and flexible electronic devices: Being wearable with hundreds of components including a battery, an AR device has to be compact, lightweight, efficient, and safe

Image source: Facebook

For example, Facebook and Bosch have collaborated to develop smart glasses for the masses, similar to wearable smart watches, which may revolutionize the consumer electronics industry.

This article is a product of the International Society of Automation (ISA) Smart Manufacturing & IIoT Division.