The advancement of the Fourth Industrial Revolution (4IR) has brought about pivotal technological developments. These include artificial intelligence (AI) and automation, big data analytics, and cloud technology. Meanwhile, manufacturers face capacity, performance, and innovation pressures. Many of these pressures can be alleviated through digital transformation. However, the longstanding insight that embracing digitalization requires workforces to “fundamentally alter traditional ways of doing business processes and relationships” still holds true.

In light of this, it’s not surprising that most manufacturers understand the potential benefits of 4IR initiatives while struggling to fully enact them. AI-as-a-Service (AIaaS) solutions can work to dissolve barriers to digital transformation—in concert with the right technology stack.

4IR Challenges Manufacturers Face

Let us first delineate some of the key forces advanced manufacturers need to work with as they evolve production:

- Labor and skills shortages

- Supply chain disruptions

- Sustainability mandates

- Increased mass and complexity of industrial data

- Rapid technological advancement of competitors

Regarding labor, there is a mismatch between the number of workers available and the skills needed to fill open jobs. In other words, there is not enough in-house expertise to fully capture the additional value offered by industry 4.0. Furthermore, organizations are required to comply with various sustainability regulations. These have been put in place to help steer the industry toward net-zero by 2050. Failure to comply is often met with costly penalties.

Holding back sustainability and process optimization initiatives is the increasing complexity of industrial data. Manufacturers struggle to get the relevant data from the hundreds of parameters impacting their processes into one place such that it is valuable and ready for use. Adding to the pressure, the manufacturing sector must contend with supply chain disruptions and the often rapid technological advancement of competitors.

How Data-to-Value IIoT Technology Solves Manufacturing Challenges

It all begins with data. Data is essential for powering the factories of tomorrow and empowering the people who run them. To ensure the effective centralization and visualization of production data, manufacturers need a complete industrial internet of things (IIoT) connectivity solution predicated on value.

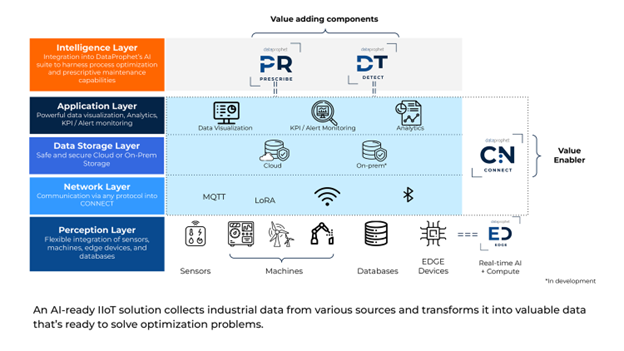

Current IIoT platforms collect raw feeds from sensors, programmable logic controllers (PLCs), supervisory control and data acquisitions (SCADAs), and historians, as well as quality data recorded in the quality management system (QMS), enterprise resource planning (ERP), manufacturing execution system (MES), spreadsheets, and other files. It should be noted, however, that not all such cyber-physical systems work to ensure that the relevant data is contextualized, current, and complete. In other words, a plant’s IIoT stack is little more than a monitoring and visualization tool—unless it renders optimization-critical data available for AI modeling. Only then will industrial data yield actionable insights that drive value.

AI-ready IIoT empowers manufacturers to log, trace, and visualize all processes relevant to production in real-time and in one central location, but it only tackles half of the data-to-value equation.

AI-ready IIoT empowers manufacturers to log, trace, and visualize all processes relevant to production in real-time and in one central location, but it only tackles half of the data-to-value equation.

Deep Learning Optimization for Manufacturing 4.0

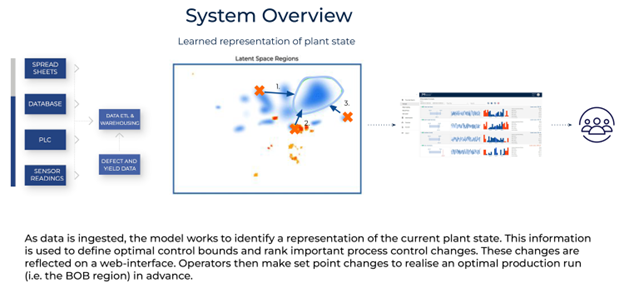

The second half of the data maturity equation is solved with AI. However, the type of machine learning (ML) under consideration matters. Deep learning, for example, leans into AI’s capacity to generate insights into the material flow of a complex industrial process using process and quality data. Applied as prescriptive analytics, it has been proven to leverage AI-ready data to optimize production processes preemptively and holistically.

By applying deep learning for prescriptive control, innovative manufacturers are proactively optimizing their processes against critical key performance indicators (KPIs). Moreover, because the fuel for the technology is production data, this AI is proving successful across a range of verticals, including gray iron foundries, automotive, welding, metalworking, mineral processing, and semiconductors.

How does it work?

An expert execution system (EES) continually correlates historical production data with the latest production state to provide prescriptions that will take the production line from a suboptimal state to its best-of-best (BOB) operating region.

The implementation of these AI-driven digital solutions can resolve many of the ongoing production process optimization and data-readiness issues experienced by manufacturers.

The implementation of these AI-driven digital solutions can resolve many of the ongoing production process optimization and data-readiness issues experienced by manufacturers.

Barriers Preventing Industry 4.0 Adoption

While such value-driven digital transformation appears to be a potent remedy to many manufacturing pain points, it is often met with resistance. In general, there’s a perception that the adoption of emerging technologies will disrupt ongoing operations and shift the structure of existing jobs—negatively affecting output and creating challenges in the labor market.

In the manufacturing space, plant engineers and operators often show an unwillingness to adopt new technologies due partly to knowledge domain skepticism. This is often based on a lack of familiarity with, and trust in, algorithmic business thinking. To embed digital skills into standard operating procedures, a data-driven mindset is vital.

Embedding Digital Skills with AIaaS

To achieve it, manufacturers need to adopt holistic solutions that digitally align with manufacturing subject matter experts (SMEs), operators, and data science/ML experts. Having these stakeholders co-create value will ensure key personnel are upskilled to make practical use of their plant data. They will also be motivated to change their standard operating procedures. AIaaS is a solution fit for the smart factory change management challenge.

AIaaS means ongoing and complete support for factory personnel and solutions tailored to an individualized factory context. During a collaborative journey, the specific data maturity and optimization needs of the production environment are established at the outset. Delivered as a service, the right AI solutions enable manufacturers to continually optimize any advanced, multi-step production process as they digitally transform.

Value-Tracking and Measurement for Collaborative 41R Stakeholders

AIaaS also allows for collaborative value tracking and measurement. Here, the AI solution benchmarks various metrics the manufacturer wants to optimize. These may include quality, uptime, throughput, and overall equipment effectiveness (OEE). The AI specialist then leverages production data to generate targeted adjustments for plant engineers to incorporate into their control plan and for operators to apply. With prescription compliance built into the agreement, the manufacturer and technology vendor can track production efficiency and process improvement data—as per the agreed benchmarks.

On the journey, a knowledge-sharing and digitally curious mindset are indispensable. AIaaS ensures information technology (IT) people, operations technology (OT) departments, manufacturing experts, and the technology vendor work together. Stakeholders involved in this collaboration include IT managers, process engineers, operators, plant managers, executives, and data scientists (ideally, with manufacturing and engineering experience):

- IT managers: AIaaS works with IT managers by providing an end-to-end solution that works on top of existing data collection investments.

- Process engineers: By ensuring contextualized, current, and complete data, AIaaS solutions allow process engineers to innovate, rather than reactively troubleshoot.

- Operators: The AI solution adaptively identifies optimally prioritized actions on a real-time dashboard for plant operators to apply in advance of missed KPIs.

- Managers and executives: AIaaS solutions lead to satisfied customers, empowered teams, better workflows, and improved margins.

- Technology vendors: Data scientists, engineers, and software specialists ensure the effectiveness of the solution and continuous support to the plant.

In this way, AIaaS pulls together each stakeholder to work around a common value-driven digital transformation goal.

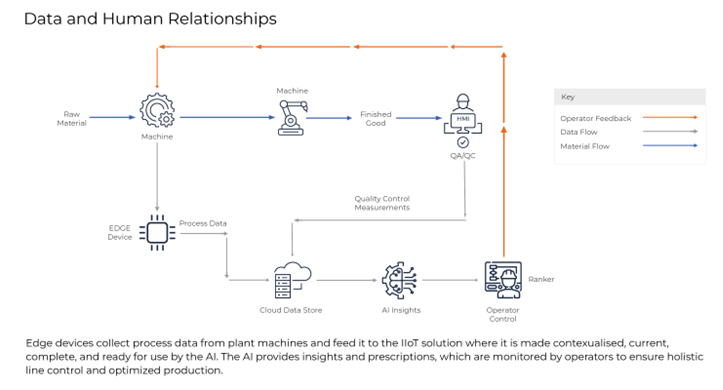

Human-Machine AIaaS Update Loop

The diagram below illustrates the relationships between humans, machines, and AI. The AIaaS update loop reflects a partnership ecosystem in which plant personnel, the technology vendor, and machine learning insights co-create digital value symbiotically.

Start Your Digital Maturity Journey

Start Your Digital Maturity Journey

By embracing digital transformation, manufacturers can address many of the challenges posed by industry 4.0. AIaaS solutions provide a means to reframe human change barriers as opportunities. Value-driven digital transformation towards a common goal ensures a more seamless transition to the factories of tomorrow for manufacturers—where innovative capabilities, algorithmic data literacy, and adaptability will be the new normal.