We all want the inside story. Greater visibility into asset performance gives chemical and energy companies a competitive edge. Having a better understanding of column hydraulic performance can significantly improve asset utilization and reduce capital costs in revamp projects and new designs. Predicting the performance of units is critical for simulating towers for process design, performance, and reconciliation. If process engineers can see precisely what is happening to the behavior of trayed and packed columns, they can quickly get to the root cause of operational issues and make informed decisions.

With advanced simulation tools, new and experienced engineers can easily look inside the column to troubleshoot operational issues and evaluate the best options for efficiently designing new and existing units. Using interactive functionalities with enhanced software calculations, engineers can visualize the entire column’s behavior to better understand the occurrence of problems like flooding or weeping, as well as how adjacent equipment and changing process conditions can affect the column. Essentially, better decision support reduces costs, time, and project and operability risks.

Highly complex system

Distillation column analysis is one of the key areas of focus for chemical engineers. Gaining detailed knowledge of column internals is a high priority for engineers, especially regarding the behavior of equipment and processes. As one of the most expensive and energy-consuming units in a plant, the fluid dynamics of the column can be complex.

Distillation columns are one of the most difficult design and operational challenges in the process industry. According to the U.S. Department of Energy, more than 40,000 distillation columns are involved in plant operations in the chemical and petrochemical industries in North America, and they consume approximately 40 percent of the total energy used. Owner-operators always want to improve capacity, product quality, and energy efficiency through debottlenecking or operational troubleshooting. Depending on the complexity of the task, further help from in-house column experts or engineering firms may be needed.

The availability of light crude oils and low natural gas prices, particularly in the U.S., is propelling debottlenecking projects related to columns in both the chemical and energy sectors. Many process engineers find it difficult to optimize the column and the whole process together. For revamp projects to increase capacity, they may face limited rating capabilities and be drawn into iterative design studies with manual, error-prone data transfer between the simulator and other tools. Column specialists typically want to predict when there is a high risk of a column not behaving well (e.g., flooding, weeping, pressure swings) and be able to quickly evaluate across the full range of design conditions, safety margins, and normal operation levels.

When capital is needed to debottleneck a process, engineers within engineering and construction companies are similarly focused on minimizing project capital expenditure by reusing existing equipment (i.e., shell, piping), investing in lower-cost adjacent equipment (like feed heaters and coolers), or replacing the column internals and evaluating different internal configurations to find the most economical option.

In improving operations, process engineers are focused on driving efficiencies and making safe, confident decisions. For owner-operators, it is vital to increase capacity, minimize operational expenditure, optimize product quality, and troubleshoot operational issues. By determining issues quickly, it is possible to reduce costly shutdowns and expensive physical investigations. Pushing the capacity of the column, while operating close to safety constraints, is important to optimize production performance. It is also a high priority to minimize costs by optimizing conditions and reducing energy usage.

In designing new columns, process engineers use process simulators and column vendor tools so designs meet operability guarantees, while also minimizing capital costs when selecting columns and column internals. New columns need to be properly sized to perform adequately for the process requirements, to minimize operating costs, and to avoid future operational issues. Design rules of thumb differ for clients and process applications. Keeping track of those guidelines and applying them where needed is time consuming.

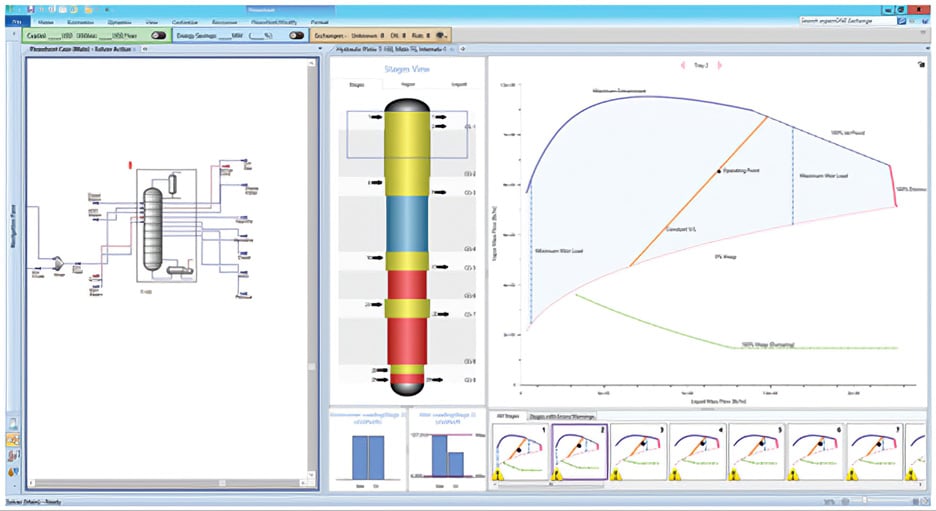

Cutting-edge simulation technology helps users better understand the behavior of columns. They can swiftly address or predict operational issues by seeing the entire column in one view with a visual presentation of inputs and results. The tools offer clear messages to explain problems with potential solutions. In addition, engineers can look at the column as part of the larger process with an interactive solver for quickly evaluating multiple design options and operating cases.

Users can improve workflow by creating and analyzing column tray and packed sections for hydraulic design and rating using an interactive sizing mode. Engineers can tune their designs to perform within hydraulic limits by using hydraulic plots and clear system messages to quickly compare the results of multiple designs. A process simulator allows users to change operating conditions on the flowsheet, visualize and observe changes to hydraulic behavior, and make adjustments to create an optimal design. Column analysis makes it simpler to gain insights into column performance problems.

New functionality in process simulation and process optimization software enables engineers to optimize energy use in columns and quickly pinpoint potential issues at the design stage, when troubleshooting poor operational performance, or for revamp projects.

New functionality in process simulation and process optimization software enables engineers to optimize energy use in columns and quickly pinpoint potential issues at the design stage, when troubleshooting poor operational performance, or for revamp projects.

Column performance

Software suppliers have incorporated new functionality in process simulation and process optimization software. Engineers can optimize energy use in columns and quickly spot potential issues affecting the unit—whether at the design stage, when troubleshooting poor operational performance, or for revamp projects.

With enhanced hydraulic correlations, it is possible to decrease assumptions and produce more accurate modeling for column analysis. Intuitive, interactive, and visual graphics for tray geometry or packing inputs and the resulting hydraulic plots for every stage give greater detail about the hydraulic behavior of the individual stages. They simultaneously show the performance of the whole column. The ability to easily evaluate the effects of changes in flowsheet inputs, as well as internal geometry on hydraulic performance, produces better troubleshooting and design.

The main benefits of using advanced process simulation and process optimization software for column analysis are:

- quicker insights into column performance problems and behavior based on current operating conditions

- the ability to see the column as part of the larger process with an interactive solver for evaluating multiple design options and operating cases

- the ability to evaluate interactivity between columns and other equipment before making operations/revamp decisions

- the ability to evaluate multiple revamp options for more informed discussion with vendors

- automated sizing capabilities and design templates that save time and effort when designing a new column and help less experienced users get up to speed

- reduced time and manual labor iterating between process data in the process simulation or process optimization software and column analysis with third-party tools with automatic export of geometry and process data

Seeing the whole picture

Greater visibility into asset performance provides the platform for better decision making. Advanced process simulation offers engineers powerful chemical engineering capabilities for column analysis. Gaining insight into key processes enables better and faster problem solving. With new column analysis capabilities, engineers can troubleshoot operational issues and evaluate new and revamp options with an interactive tool offering enhanced calculations and visualizations.

The inside story is that column design and rating no longer needs to be done in isolation or viewed as a mysterious black box. Visualizing operations can be done within an advanced process simulator to fully understand the behavior of a critical capital and energy-intensive piece of equipment. As a result, engineers can minimize capital expenditure and make discerning design decisions that affect the entire plant performance—great news for improving performance and increasing profitability.

A version of this article also was published at InTech magazine.