Introduction

In the last 40 years, process control and automation systems in the hydrocarbon processing industry have gone through tremendous change. Latest advancements in digital technologies in the last 10 years have paved the way for many operational excellence opportunities, such as production and loss monitoring, process optimization, process data analytics, and more.

The hydrocarbon processing industry handles large amounts of hydrocarbon production, consumption, storage, and movement data, and it is virtually impossible to manually verify and validate measurements. With accurate and timely accounting of the hydrocarbon flows and inventories, the industry is able to make proper business decisions to ensure that production plans and schedules are met. There is a need to have a comprehensive system to provide accurate and quality data to stakeholders to make optimum planning, scheduling, and supply chain decisions.

Vision

To maximize the full financial value of production by reducing unaccounted losses at par with industry benchmarks by providing a platform for daily data reconciliation and production accounting.

Business Process

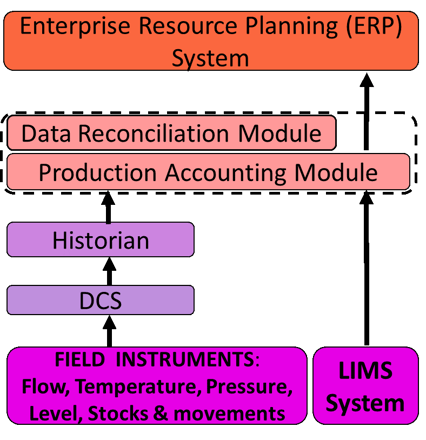

Considering implementation of automated hydrocarbon production and loss accounting, selection of the right measurement technology is the most important step in the process, as measurement has a huge impact in closing daily mass balances. Provision of an adequate number of measurement points with redundancies for key measurements need to be ensured. Upon selection of measuring devices, below are a few important steps in the process:

- Production accounting business process, along with automated workflows embedded with best industry practices and an integration with a company’s ERP system. Important checks like review and diagnosis of reconciliation results, bad meter identification, site-wise MIS reports, and post export of data to the ERP system needs to be included.

- Selection of data reconciliation software: The quality of process data in the hydrocarbon processing industry significantly affects the performance monitoring and benefits realized. Data reconciliation software supported with gross error detection techniques act as an intuitive expert for providing quality process data, while complying with industry auditing standards. Software should also have a robust solver to reconcile and validate raw plant measurements, which can then be further utilized for performance monitoring and optimization. Some data reconciliation software available in the market: Sigmafine by PimSoft, Aspen’s Operations reconciliation and accounting, DVR by Belsim Vali, PAR by Honeywell, and Error Solver by Aveva.

- Production accounting repository: After the selection of data reconciliation software, there is a need for a good production accounting repository/database. Most of the data reconciliation software solutions today come with a database/repository integrated with data reconciliation software. Raw and reconciled results can be historized in such repositories and used for future reference. Old data reconciliation software used real-time data historians as repository. It is a good practice to have a dedicated repository integrated within data reconciliation software.

The overall process is explained below:

Benefits

Benefits

An investment in automated hydrocarbon production and loss monitoring is regarded as highly profitable as performance in top quartile is ensured. There are also numerous benefits:

- Accuracy of data: Improved data accuracy by reconciling and validating process data before it is finally uploaded to a business/ERP system for commercial purpose.

- Consistency: Data reconciliation software gives the confidence of validated data one can trust, or what we call a “single version of truth.” One can be certain that the data is consistent across plants and thus enables teams to act quickly.

- Speed: Enables accurate and agile decision-making by delivering timely and accurate information across the enterprise.

- Improved reliability of measurement systems: Data reconciliation software helps in identifying instrument drift or bias, and maintenance activities can be accordingly prioritized.

- Loss control: Reduction in production losses is achieved through automated monitoring that immediately identifies faulty processes and instruments.

- Improved productivity: Substantial reduction of manhours is ensured by automating the process, with elimination of inefficient work processes, by implementing industry best practices and knowledge.

- Remote working is becoming the new normal: Software application needs to be geared up towards the seamless integration of data, information, and automated workflows.

- Regulatory compliance: Data generated by automated system can be used for regulatory compliance purposes as norms pertaining to fugitive and other emissions are getting stringent every day as part of carbon footprint reduction.

- Automated reporting: Facilitating publishing reconciled inventory, production, consumption, receipts, and shipment reports, integrating with other applications for further analysis.

Operational Excellence

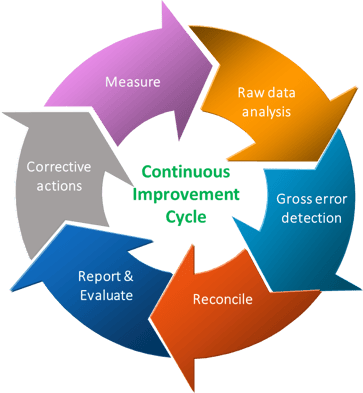

Operational excellence is the goal of all organizations striving for continuous improvement. By embracing automated hydrocarbon production and loss monitoring, business processes, and best practices, sustainable improvement in an organization can be achieved.

Perfection in almost every area of hydrocarbon processing—be it tank stock accounting, solid accounting, flaring losses accounting, fuel gas accounting, and even utilities accounting, can be attained by simplifying work without compromising the quality of outcomes.

Many times, there is no indication of what action plant personnel need to make to reduce loss and improve profitability. It is therefore necessary to apply engineering knowledge and judgement to analyze the results of the material balance further. Digital technologies like data analytics and AI/ML can also be explored to bring in “operational insight.” Large complexes operating in multi-site, multi-plant environments can also leverage cloud-based solutions.

About the Author

About the Author

Vikas Deshmukh is serving as Vice President with RIL’s (Reliance Industries Limited, India) Technology Centre of excellence at Navi Mumbai, India. He holds a degree in Petrochemical engineering, and an MBA and PG diploma in Supply chain management. Vikas carries 26 years of experience in Hydrocarbon industry in various functions like operations, technical services, process automation & control. Additionally, he also has 4 years of consulting experience and has dealt with business development and solution architecting assignments. Currently @ RIL, Vikas is in a Leadership role in the Automation group, driving automation and ongoing digital transformation initiatives.

Supporting Authors

Ramesh Rajaram is the Senior Technologist at Jamnagar Manufacturing Division at Reliance Industries Limited. With more than 20+ years of experience and 13+ years at RIL, he is leading yield accounting and data reconciliation activities, acquiring expertise in production accounting, data reconciliation and offsite operation.

Ayush Agrawal is the technologist at Reliance Industries Limited. With an experience of 5+ years at RIL, he has acquired proficiency in production accounting, data reconciliation, dynamic simulation, digitalization of plant performance monitoring, and optimization.

Ayush Agrawal is the technologist at Reliance Industries Limited. With an experience of 5+ years at RIL, he has acquired proficiency in production accounting, data reconciliation, dynamic simulation, digitalization of plant performance monitoring, and optimization.