IT/OT Convergence: From Device to Database

IT/OT Convergence: From Device to Database

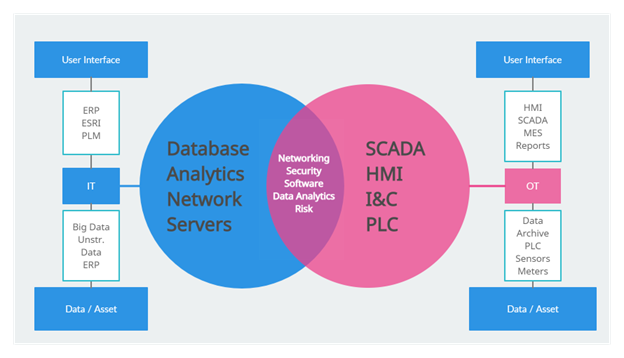

The term IT/OT convergence seems to get thrown around quite a bit these days when discussing industrial automation, but what does it really mean? Information technology (IT) systems are typically composed of database technologies, data analytics, networking devices, and software applications and are primarily used for data-centric computing. Operational technology (OT) systems are designed to monitor, control, and execute the processes required for manufacturing and production facilities. OT systems include sensors, pumps, actuators (industrial controls), supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs), manufacturing execution systems (MES), distributed control system (DCS) controllers, and other devices required for production monitoring, safety, and control.

IT/OT convergence allows us to use the technological capabilities and data from traditional OT systems used in production and manufacturing, combining them with the data-centric computational and analytical analysis of IT systems. Simply put, we can now gather data from the OT systems and use IT systems to analyze the data and make decisions on process design, control, improvement, and maintenance. IT/OT convergence allows us to take the data collected by traditional OT systems and processes to gain valuable insights.

But where does that leave the traditional OT/SCADA specialist? In the Industry 4.0 world, a production facility needs to have a controls specialist, SCADA specialist, database administrator, IT specialist (CST, programmer, etc.), and network engineer just to keep up with the demand in technological advancement and regulatory requirements. Having all of these specialists is cumbersome at best and generally economically infeasible, especially for non-profit utilities and corporations.

This leaves us with two choices: We can integrate IT and OT departments, or we can equip our OT specialists with the required skillsets necessary to build and maintain both systems. As we are trying to maintain segmentation between IT and OT networks, it would seem logical to provide our traditional SCADA specialist with the IT skillset to accommodate IT/OT convergence rather than bringing IT departments into the OT environment.

Full-Stack OT Specialists

Is it now time for a full-stack OT specialist? In the same way a full-stack developer in the web development world works with everything from servers to the user interface/user experience design (UI/UX) or front-end graphics, the full-stack OT specialist should have the skills to work with everything from the device to the database. A full-stack OT specialist should be equipped with the ability to understand, maintain, and troubleshoot traditional IT assets such as PCs, servers, and network hardware and architecture. They should also have the ability to deploy and administer database solutions and implement cybersecurity, network, and redundancy policies.

In today's world, with such a large focus on industrial cybersecurity, a full-stack OT developer could potentially have better insight into potential gaps in security protocols and policies. Having an understanding of how the entire system works together to facilitate safety and security reveals gaps in systems that would not be obvious to an individual specialist (SCADA specialist, controls specialist, etc.). While this may seem like quite a large undertaking, many SCADA specialists already understand these technologies; they just have to apply an IT mindset to what they already do.

Conclusion

Bottom line, it is generally more valuable to provide OT specialists with the ability to manage IT assets (network switches, firewalls, PCs, servers, etc.) and learn traditional coding concepts and languages (python, SQL, visual basic, etc.). This not only allows a better understanding of the systems as a whole, but also allows for more rapid response in an emergency response plan (ERP), as well as the ability to detect and correct the issue(s) that caused the emergency response, protecting the industrial control system (ICS) from further exploitation. This gives OT specialists another set of skills that can be used to solve everything from complex control narratives, to UI/UX design, to changes that can help improve operator response and efficiency.

Thankfully, the information age has given us the ability to learn these necessary skills at the tips of our fingers. With resources like LinkedIn Learning, Coursera, MIT OpenCourseWare, Udemy and other online free or inexpensive learning and content platforms (many libraries have contracts for free learning with your library card) we now have the ability to learn valuable IT and coding skills for almost no cost outside of an investment of time.